Hydraulic braking system with energy feedback and esp function and its control method

A technology of hydraulic braking and energy feedback, applied in ESP control system, braking control system, hydraulic braking transmission device, etc., can solve the problems of high cost and difficult manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

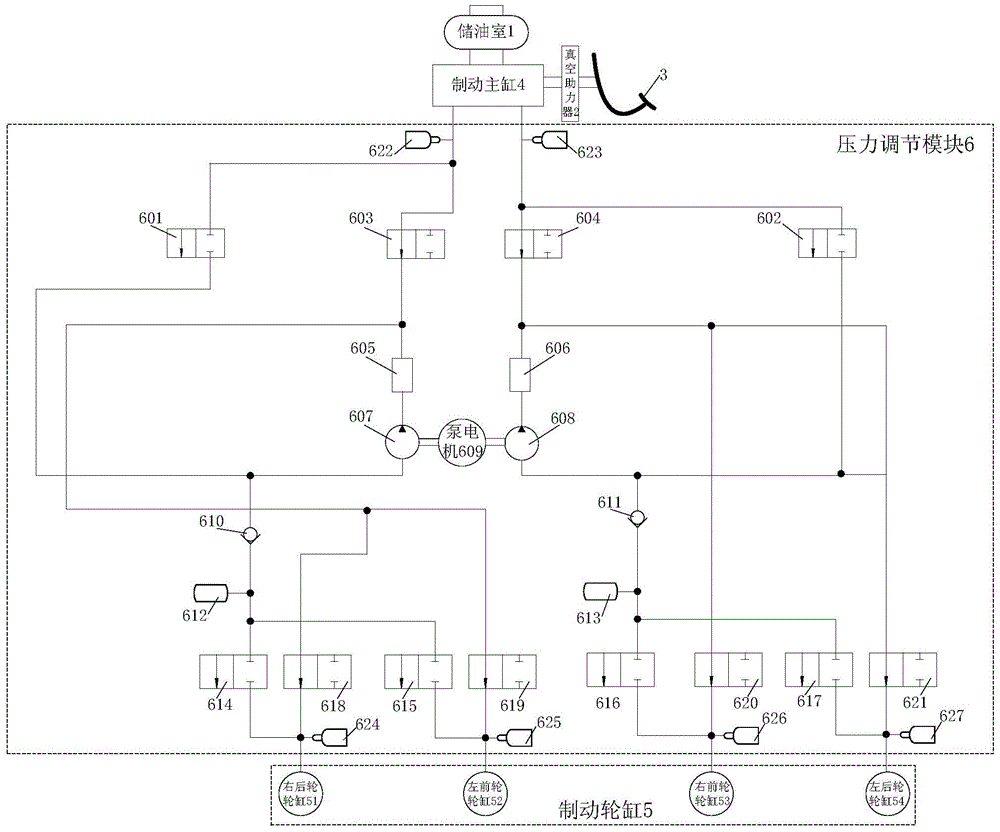

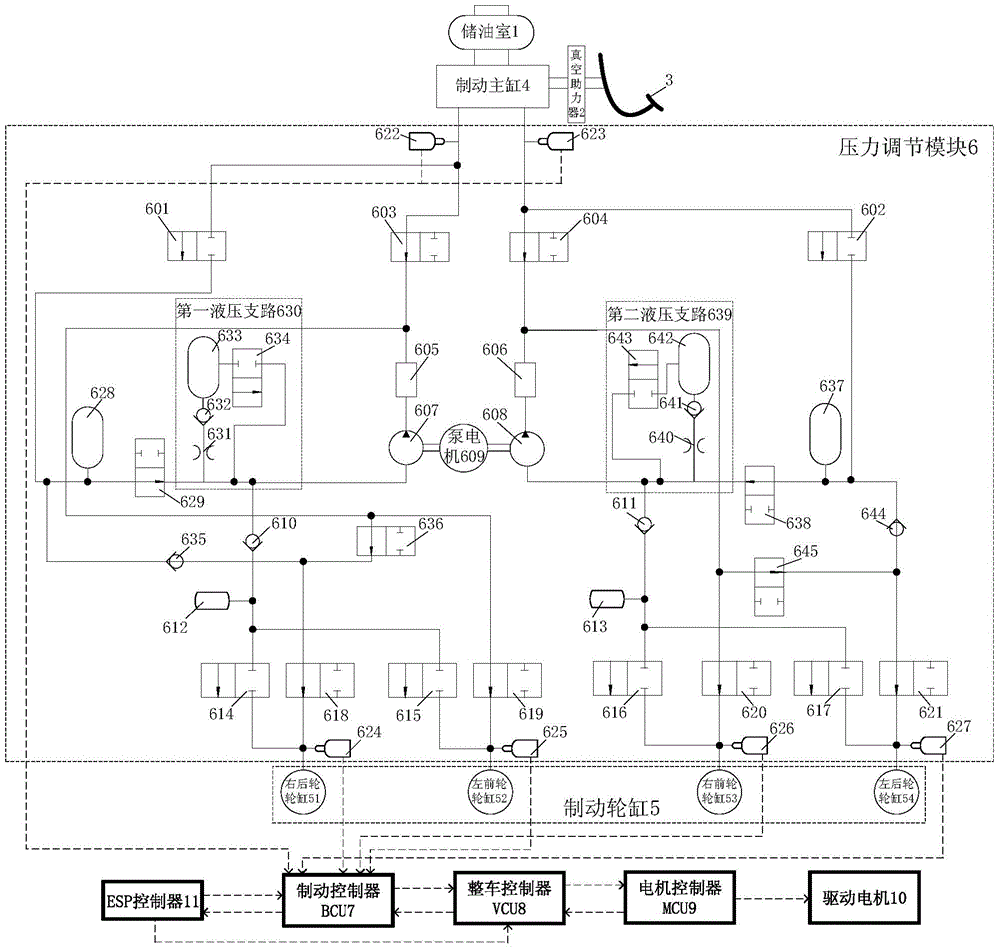

[0015] Such as figure 1 As shown, the hydraulic pipeline in the traditional vehicle dynamics control system is mainly composed of oil storage chamber 1, vacuum booster 2, brake pedal 3, brake master cylinder 4, brake wheel cylinder 5 and pressure adjustment module 6, etc. . The brake master cylinder 4 controls the pressure of the brake wheel cylinder 5 through the X-shaped oil circuit and the pressure regulating module 6 provided on the oil circuit. Wherein, the brake wheel cylinder 5 includes a right rear wheel cylinder 51 , a left front wheel cylinder 52 , a right front wheel cylinder 53 and a left rear wheel cylinder 54 . The brake master cylinder 4 controls the right rear wheel cylinder 51 and the left front wheel cylinder 52 respectively through the first oil circuit, and controls the right front wheel cylinder 53 and the left rear wheel cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com