Piling ship

A technology of piling ship and piling platform, which is applied to special-purpose ships, ships, motor vehicles, etc. It can solve the problems that the piling ship cannot drive multiple piles with high precision, and the piling ship is greatly affected by wind and waves, so as to achieve control that is beneficial to precision , The impact of wind and waves is small, and the effect of reducing the windward receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

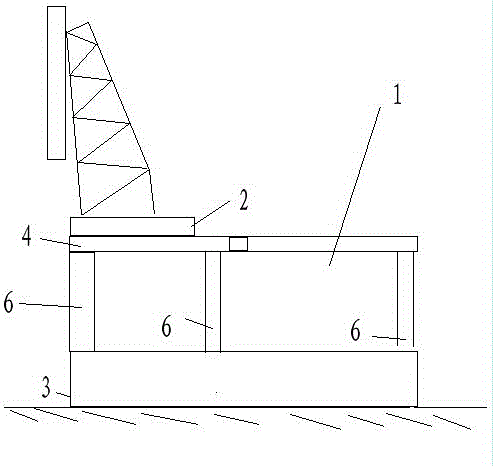

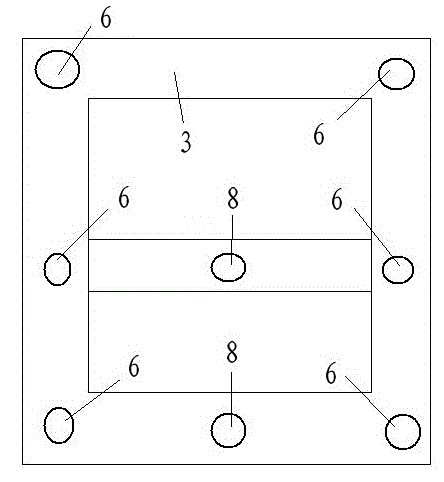

[0040] A piling ship includes a hull and a sliding piling platform, the hull includes a base and an adjustable rotating deck, the base includes a plurality of hollow cavities, the base and the adjustable rotating deck are connected through support columns, the The above-mentioned base is provided with a ballasting and loading device for water, and the said ballasting and loading device is used for pumping or filling water from the hollow cavity, thereby controlling the floating and sinking of the hull,

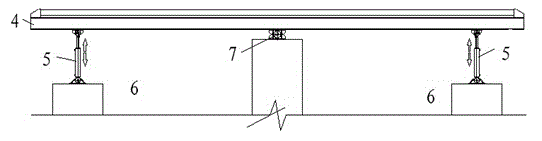

[0041] The adjustable rotating deck includes a rotating platform, at least 2 rotating supports, and 4 supporting supports. The supporting columns are respectively located in the middle of the base and the four corners, and the middle columns are connected to the rotating platform through pin shafts The support columns at the four corners are connected to the rotating platform through a hydraulic support system.

[0042] There is also a fixed platform adjacent to the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com