carrier catapult

A technology for catapults and aircraft carriers, which is applied in the direction of launching/dragging transmissions, etc., which can solve the problems of high manufacturing difficulty, low ejection speed or ejection cycle, and high maintenance costs, and achieve low manufacturing difficulty, low manufacturing cost, and long manufacturing cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

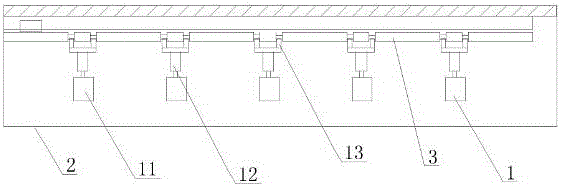

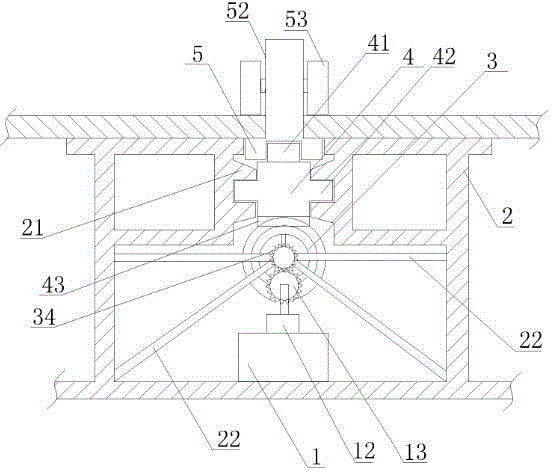

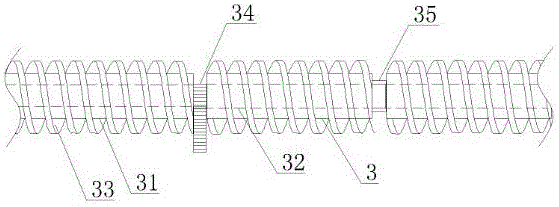

[0029] Such as figure 1 , figure 2 As shown, a carrier catapult includes a power system 1, a catapult fixed frame 2, a worm 3, a stressed slider 4, and a slide plate 5; the catapult fixed frame 2 is fixed below the deck of an aircraft carrier, and the catapult An opening is provided on the deck of the aircraft carrier above the fixed frame 2, which is commonly referred to as a slideway; one end of the slide plate 5 is located above the deck of the aircraft carrier, and the other end is socketed with the stressed slide block 4; the slide of the stressed slide block 4 The wing 42 is embedded in the slide rail 21 of the catapult fixed frame 2 and can slide in the slide rail; all the force-bearing teeth 43 below the force-bearing slider 4 are engaged with a part of the worm 3; the power system 1 drives the worm 3 turn.

[0030] Such as figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com