Manipulator for box filler

The technology of a manipulator and a cartoning machine is applied in the field of packaging, which can solve the problems of broken bottles and low production capacity, and achieves the effect of stable packing, high production capacity, and overcoming the broken bottles and broken boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

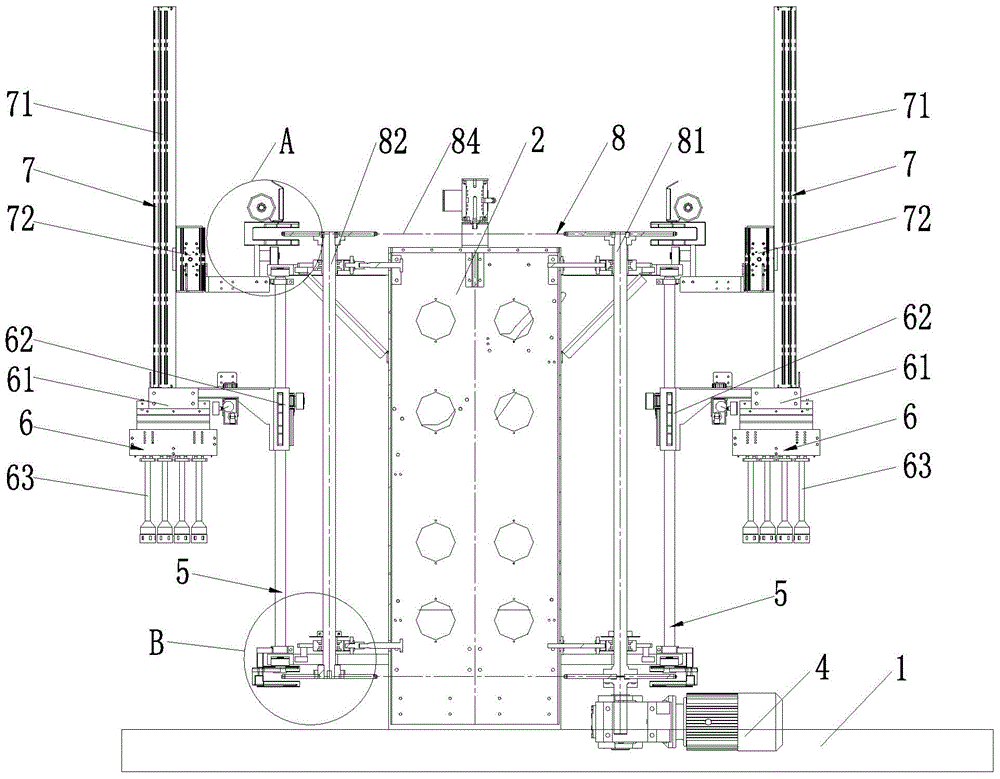

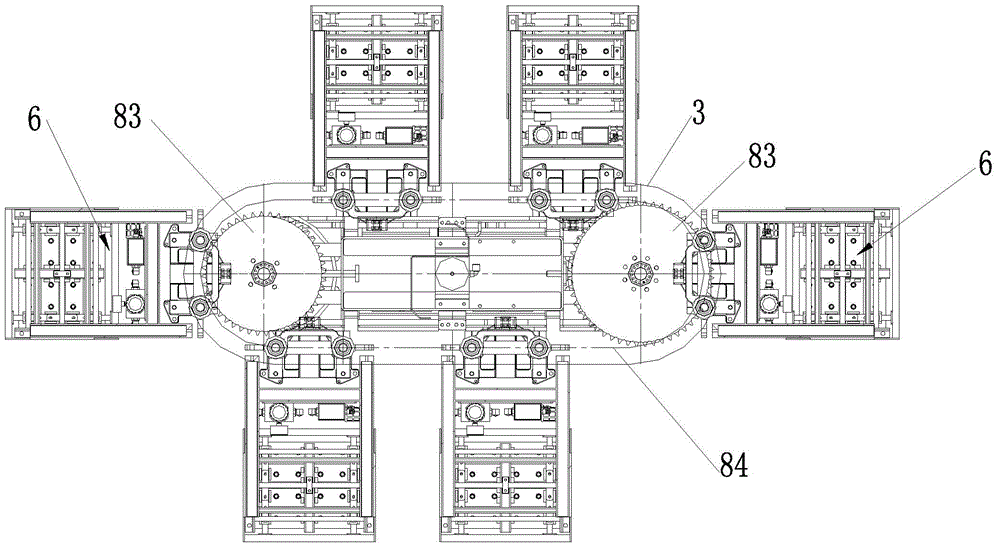

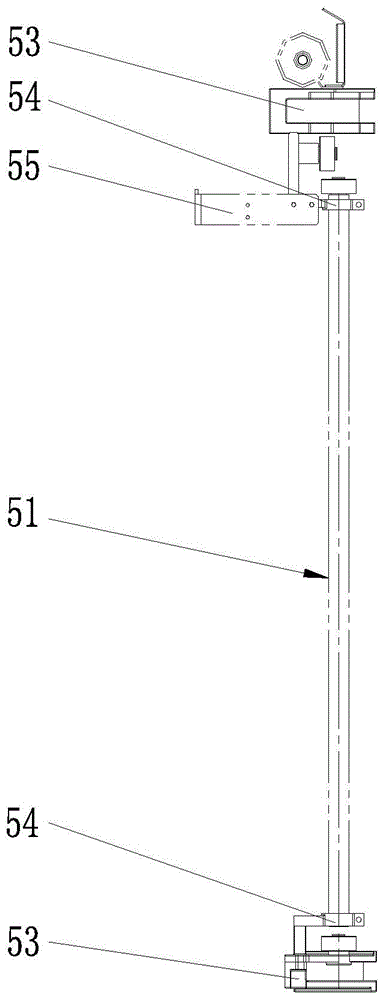

[0021] see figure 1 As shown, a manipulator for a case packing machine is installed on the frame 1 of the case packing machine. It includes a central tower 2 fixed on the frame 1, a plurality of circular guide rails 3 fixed on the central tower 2 parallel to each other, and multiple rails installed on the central tower 2 that can slide along the track of the circular guide 3. A rotating arm 5, a gripper assembly 6 mounted on each rotating arm 5 to lift and place the bottle to be boxed, the manipulator also includes a transmission that can drive the rotating arm 5 to slide along the circular guide rail 3 . In this embodiment, there are two annular guide rails 3, which are respectively located at the upper and lower ends of the central tower 2. see figure 2 As shown, there are 6 rotating arms located between the two circular guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com