Machine for separating freshness-retaining plastic cloth on tire face

A technology of plastic cloth and tread, which is applied in the field of tire machinery, can solve the problems of high rubber viscosity, difficulty of tearing off at one time, and high labor intensity, so as to improve the success rate, reduce white pollution, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

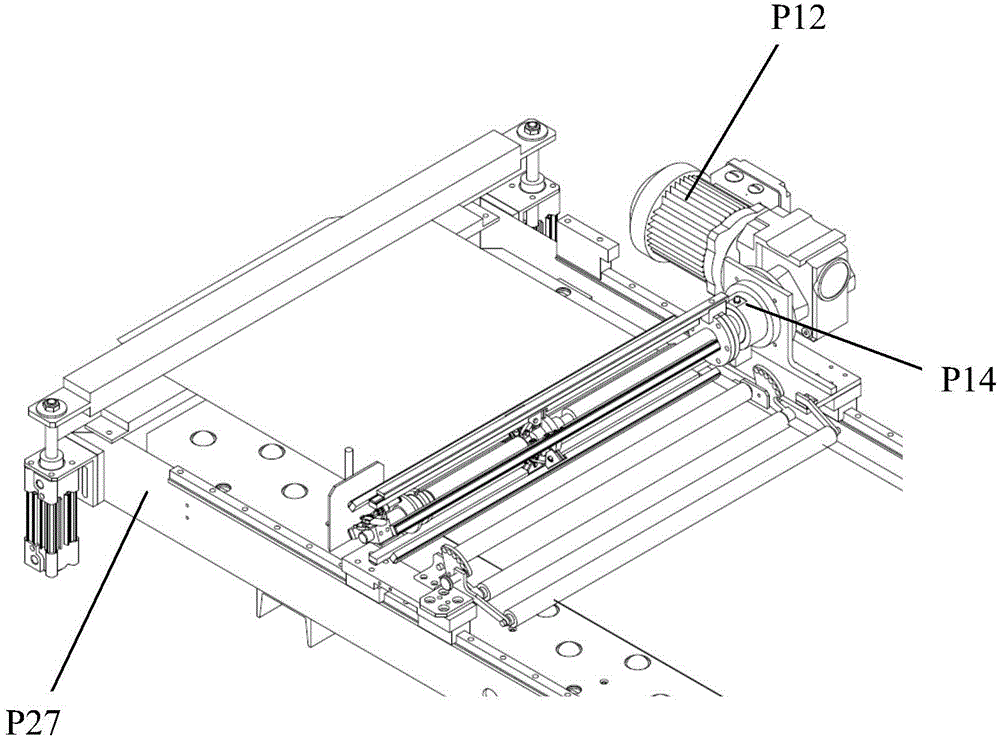

[0044] Machines that separate tread wrap, such as figure 1 As shown, it includes: tread feeding rack P27, expansion and contraction rolling device, power device, roller separation fresh-keeping plastic cloth device, and pressing device.

[0045]The tread feeding rack P27 is used to place the tread with fresh-keeping plastic cloth. Expansion and contraction rolling device is installed between the tread feeding frame P27 and is used for compressing the fresh-keeping plastic cloth head of the tread.

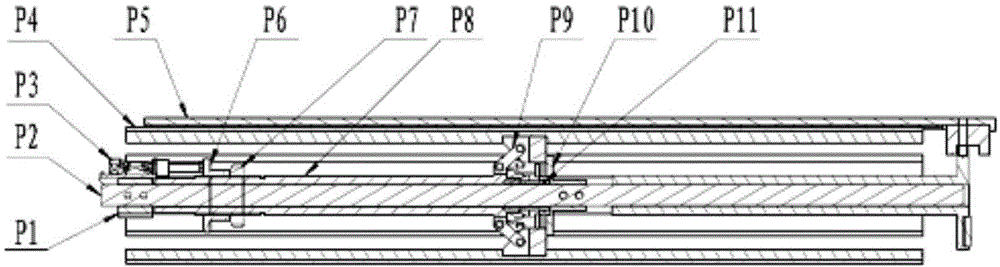

[0046] like Figure 2a to Figure 2c As shown, the structure of the expansion and contraction rolling device is:

[0047] One end of the main shaft P2 is equipped with a locking installation frame P1, and the locking installation frame P1 is equipped with a locking device P3.

[0048] The top sleeve P6 is set on the main shaft P2 in a sliding manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com