Method for producing 2,6-dimethylnaphthalene by using amylene in fischer-tropsch reaction product

A kind of technology of dimethylnaphthalene and reaction product, applied in the field of producing 2,6-dimethylnaphthalene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

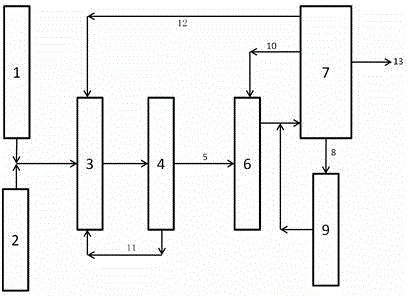

[0022] see attached figure 1 , a method for producing 2,6-dimethylnaphthalene from pentene in the Fischer-Tropsch reaction product, mainly comprising a Fischer-Tropsch pentene separation unit, an alkylation unit, a separation device, a cyclodehydrogenation unit, and an isomerization unit, 2,6-dimethylnaphthalene separation unit.

[0023] figure 1 Shown is a method of utilizing pentene in the Fischer-Tropsch reaction product to produce 2,6-dimethylnaphthalene, the Fischer-Tropsch product enters the Fischer-Tropsch pentene separation unit 1, and the pentene in the product is separated from other products, The olefins separated from the pentene separation unit are mixed with toluene 2 and then enter the alkylation unit 3. In the alkylation unit, the pentene and toluene undergo an alkylation reaction to form C 12 The mixture of polyalkylbenzenes of the components makes the pentene of the Fischer-Tropsch product react with toluene, the molar ratio of toluene to olefins is equal t...

example 2

[0027] See attached figure 1 , a method for producing 2,6-dimethylnaphthalene from pentene in the Fischer-Tropsch reaction product, mainly comprising a Fischer-Tropsch pentene separation unit, an alkylation unit, a separation device, a cyclodehydrogenation unit, and an isomerization unit, 2,6-dimethylnaphthalene separation unit.

[0028] figure 1 Shown is a method of utilizing pentene in the Fischer-Tropsch reaction product to produce 2,6-dimethylnaphthalene, the Fischer-Tropsch product enters the Fischer-Tropsch pentene separation unit 1, and the pentene in the product is separated from other products, The olefins separated from the pentene separation unit are mixed with toluene 2 and then enter the alkylation unit 3. In the alkylation unit, the pentene and toluene undergo an alkylation reaction to form C 12 The mixture of polyalkylbenzenes of the components reacts the pentene and toluene of the Fischer-Tropsch product, the molar ratio of toluene to olefin is equal to 5-9, ...

example 3

[0033] See attached figure 1 , a method for producing 2,6-dimethylnaphthalene from pentene in the Fischer-Tropsch reaction product, mainly comprising a Fischer-Tropsch pentene separation unit, an alkylation unit, a separation device, a cyclodehydrogenation unit, and an isomerization unit, 2,6-dimethylnaphthalene separation unit.

[0034] figure 1 Shown is a method of utilizing pentene in the Fischer-Tropsch reaction product to produce 2,6-dimethylnaphthalene, the Fischer-Tropsch product enters the Fischer-Tropsch pentene separation unit 1, and the pentene in the product is separated from other products, The olefins separated from the pentene separation unit are mixed with toluene 2 and then enter the alkylation unit 3. In the alkylation unit, the pentene and toluene undergo an alkylation reaction to form C 12 The mixture of polyalkylbenzenes of the components reacts the pentene and toluene of the Fischer-Tropsch product, the molar ratio of toluene and olefin is equal to 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com