A method for extracting lactoperoxidase using ultrafiltration-assisted two-phase extraction technology

A technology of lactoperoxidase and extraction technology, applied in the direction of oxidoreductase, biochemical equipment and methods, enzymes, etc., can solve the problem of lack of lactoperoxidase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

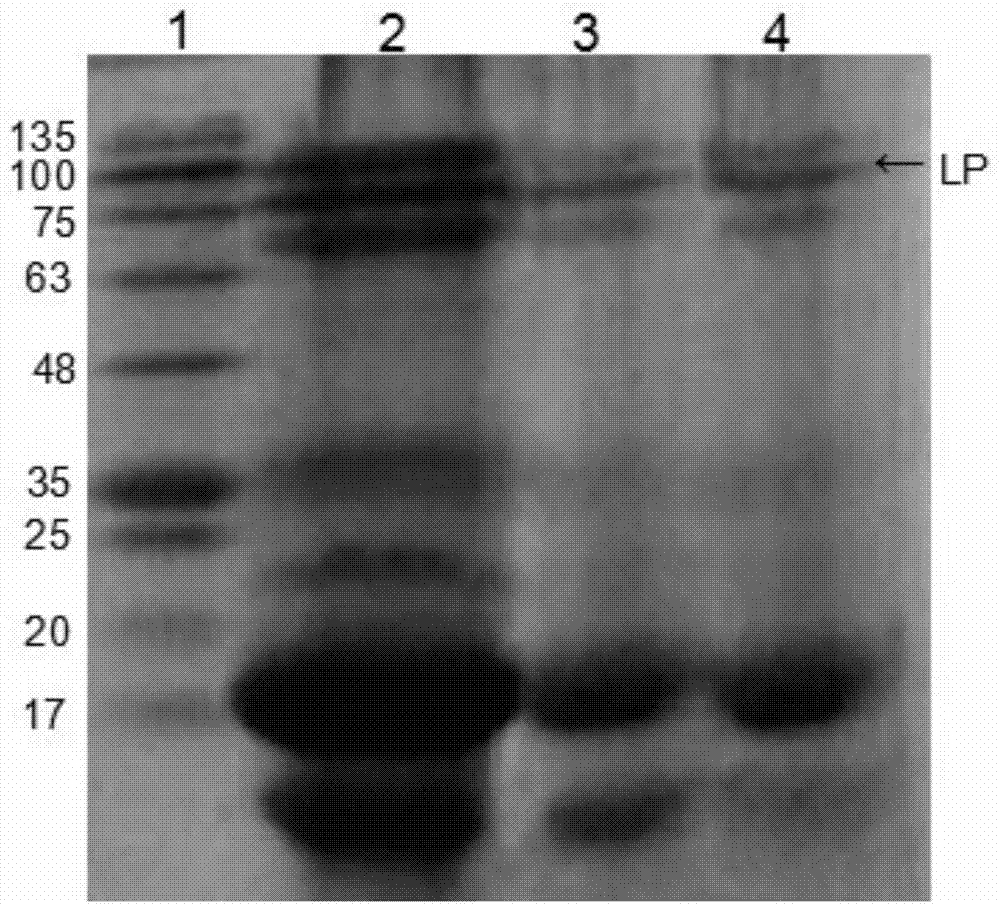

[0039] The extraction of embodiment 1 lactoperoxidase

[0040] (1) Aqueous two-phase extraction lactoperoxidase:

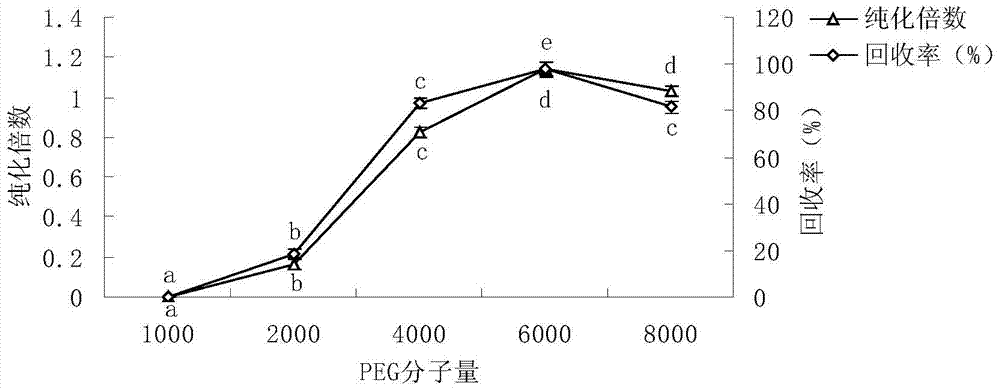

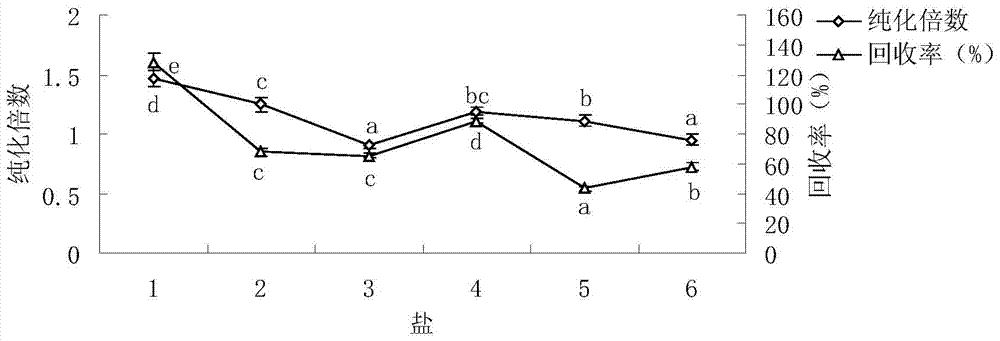

[0041] The whey is obtained after removing the fat and casein in the fresh milk. At room temperature, add an appropriate amount of whey to the container, directly add PEG and salt to the whey continuously and place it on a stirrer for continuous stirring. Until the PEG and salt are completely dissolved in the whey, an aqueous two-phase system is formed. Among them, the molecular weight of PEG is 6000Da, and the salt is MgSO 4 , the final concentration of PEG is 16% (w / w), MgSO 4 The final concentration of the solution was 10% (w / w), and the pH of the system was adjusted to 8.5 with 1 mol / L NaOH, and stood still for about 30 minutes. After the two phases were completely separated, the lower phase of the system, namely the salt phase, was collected.

[0042] (2) Ultrafiltration: Use 1mol / L HCl to adjust the pH of the collected salt phase solution system to about ...

Embodiment 2

[0059] The extraction of embodiment 2 lactoperoxidase

[0060] (1) Aqueous two-phase extraction lactoperoxidase:

[0061] The whey is obtained after removing the fat and casein in the fresh milk. At room temperature, add an appropriate amount of whey to the container, directly add PEG and salt to the whey and place it on a magnetic heating stirrer continuously Stir until the PEG and salt are completely dissolved in the whey to form an aqueous two-phase system. The molecular weight of PEG is 6000Da, and the salt is MgSO 4 , the final concentration of PEG is 14% (w / w), MgSO 4 The final concentration of the solution is 12% (w / w). Use 1 mol / L NaOH to adjust the pH of the system to 8.0. Stand still in the separatory funnel for about 30 minutes until the two phases are completely separated, and collect the lower phase of the system, that is, the salt phase.

[0062] (2) Ultrafiltration: Use 1mol / L HCl to adjust the pH of the salt phase solution system of the collected lactoperoxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com