A resistance adjustment structure on a leather softening machine

A technology of resistance adjustment and softening machine, applied in the mechanical field, can solve the problems of poor leather quality, leather waste, low efficiency, etc., and achieve the effect of long service life and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

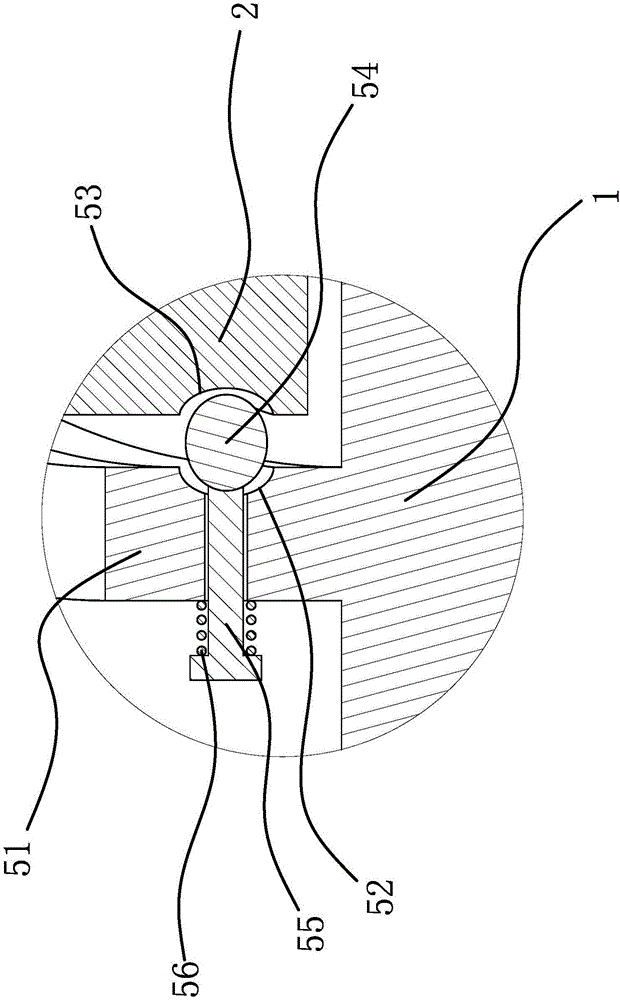

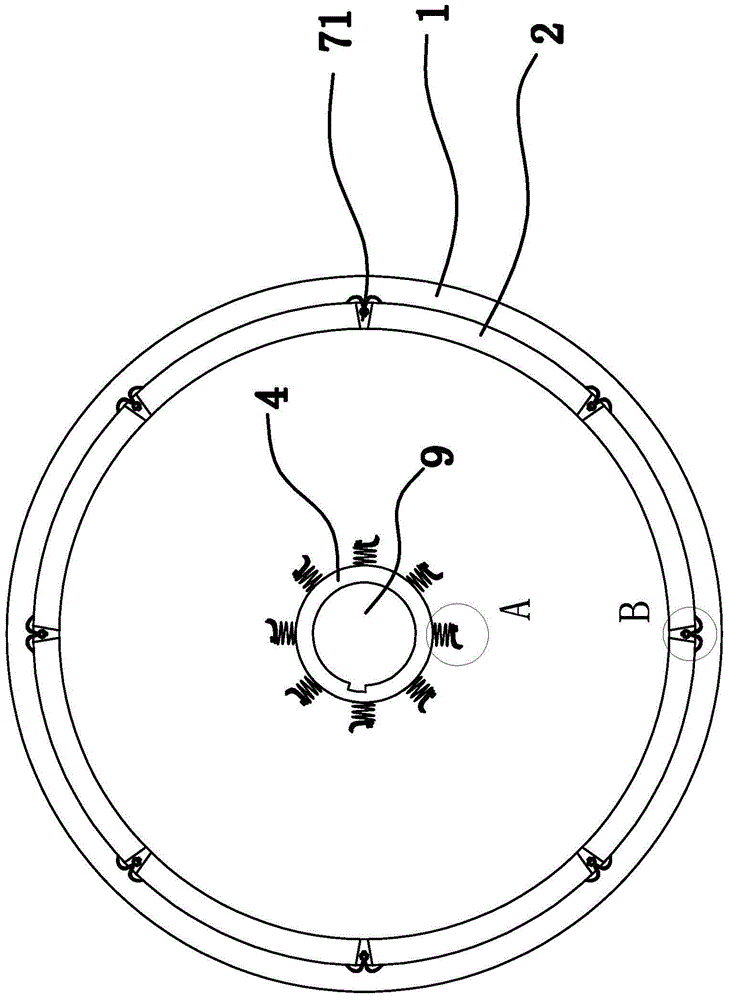

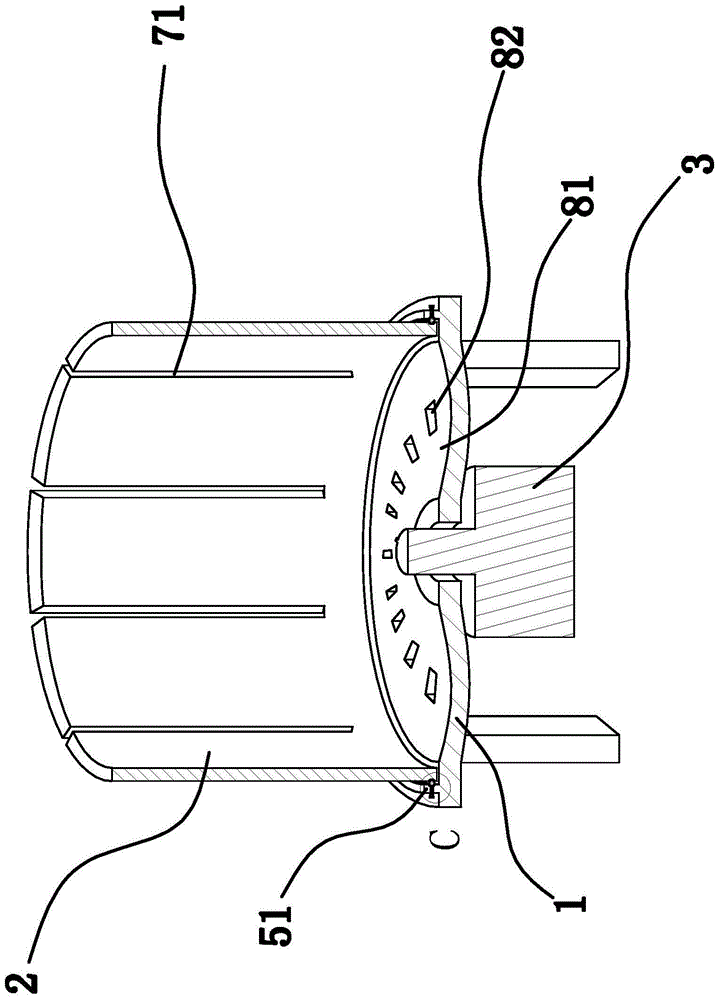

[0021] Such as figure 1 and figure 2 As shown, the leather softening machine includes a base 1 supported by several legs, a drum 2 is rotatably connected to the base 1, and a resistance adjustment structure for adjusting the rotation resistance of the drum 2 is arranged between the drum 2 and the base 1. A motor 3 is fixedly arranged on the base 1, and a rotor 4 is arranged inside the rotating drum 2, the rotor 4 can be connected with the output shaft of the motor 3, and there are a number of rotors arranged in the upper direction of the rotor 4, which can fix one side of the leather on the rotor 4. The clamping structure of the drum 2 is provided with a fixed structure corresponding to each clamping structure and capable of fixing the other side of the leather. After the leather is dried, the leather needs to be softened. This softening machine By fixing the two sides of the leather on the rotor 4 and the drum 2 respectively, the motor 3 drives the rotor 4 to rotate, and dr...

Embodiment 2

[0031] The locking spring is made of wear-resistant steel. The alloy elements of wear-resistant steel include manganese, carbon, silicon, chromium, iron, titanium, tungsten and nickel, among which manganese accounts for 8% by mass and carbon accounts for The mass percentage of silicon is 1.37%, the mass percentage of silicon is 0.04%, the mass percentage of chromium is 3.9%, the mass percentage of titanium is 0.001%, the mass percentage of tungsten is 0.001%, and the mass percentage of nickel is The mass percentage is 0.002%, and the balance is composed of iron.

Embodiment 3

[0033] The locking spring is made of wear-resistant steel. The alloy elements of wear-resistant steel include manganese, carbon, silicon, chromium, iron, titanium, tungsten and nickel. Among them, the mass percentage of manganese is 10%, and carbon The mass percentage of silicon is 1.39%, the mass percentage of silicon is 0.02%, the mass percentage of chromium is 4.0%, the mass percentage of titanium is 0.001%, the mass percentage of tungsten is 0.001%, and the nickel The mass percentage is 0.002%, and the balance is composed of iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com