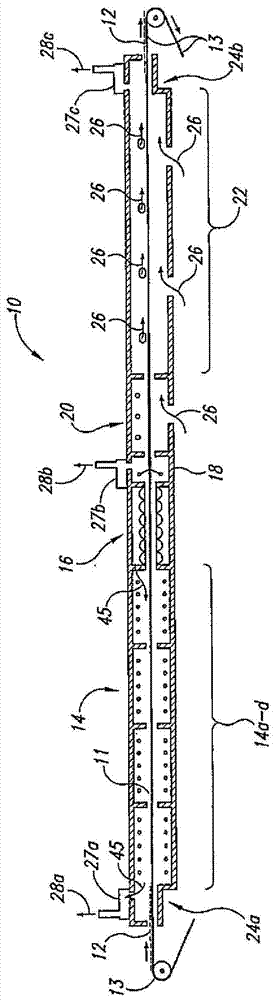

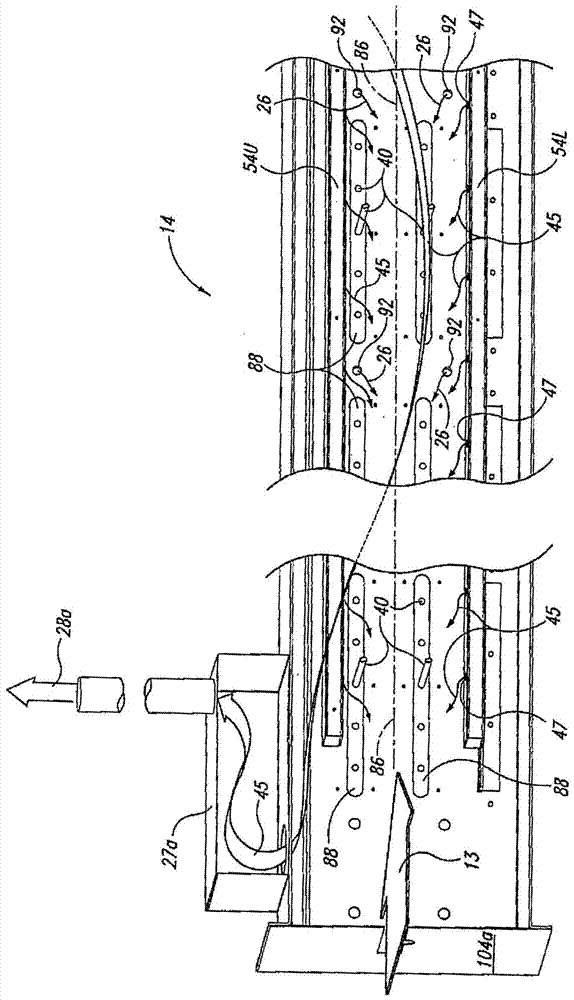

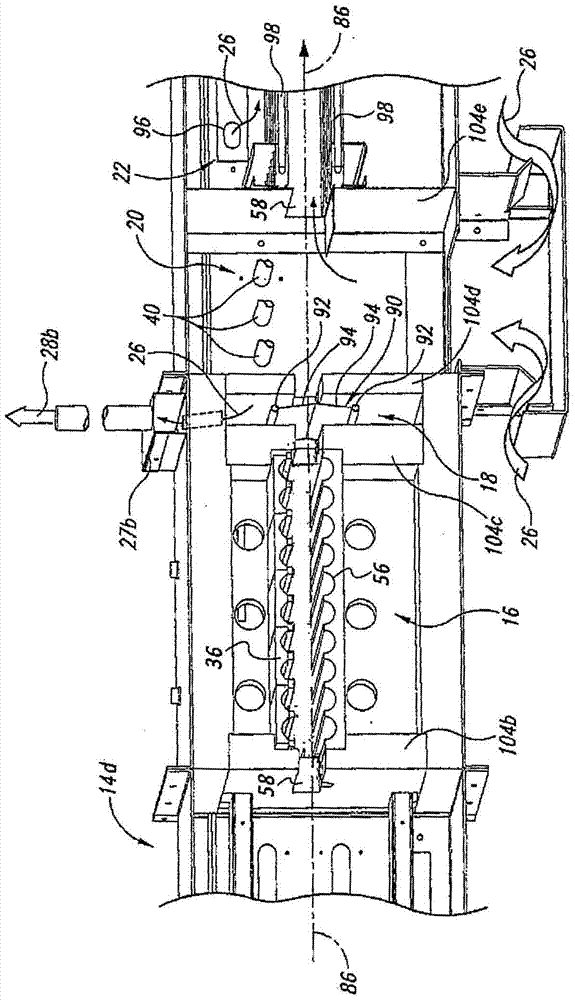

Infrared Conveyor Furnace with Single Belt and Multiple Independently Controlled Processing Lines

A conveyor, heat treatment furnace technology, applied in the direction of post-processing, post-processing details, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0131] The following embodiments illustrate the invention, but do not limit the scope, equivalents or principles of the invention. This description will clearly enable those skilled in the art to make and use the invention, and describes several embodiments, adaptations, variations, substitutions and uses of the invention.

[0132] In this regard, the invention is illustrated in several drawings and is sufficiently complex that its many parts, interrelationships and subcombinations cannot be fully described by a single patent-type drawing. For the sake of clarity and conciseness, some of the figures show schematic or omitted parts, which in the figures are not necessary to illustrate the specific features, aspects or principles disclosed in the invention. For example, the numerous electrical and pneumatic connections for lights, brakes and lift bellows, well known to those skilled in the art, are not shown in the figures. Thus, one feature may be shown in one drawing and anot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com