High activity catalyst for hydrogenation refining of Vaseline and preparation method and uses thereof

A technology for hydrofining and petroleum jelly, applied in the field of petroleum jelly hydrofining catalyst and its preparation, can solve the problems of slow reaction speed, low reaction temperature, limited catalyst activity, etc., and achieve the effect of improving activity and high activity of hydrofining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

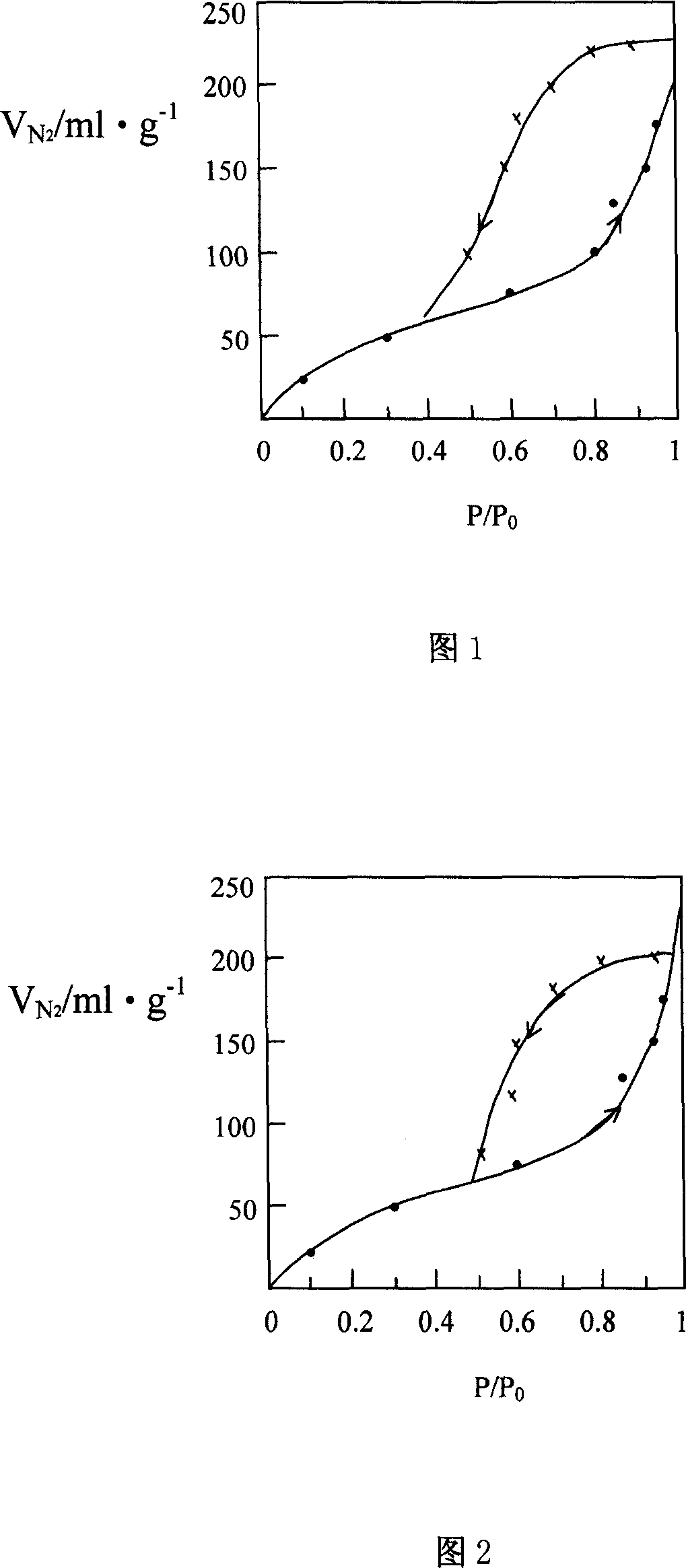

[0024] Mix macroporous aluminum hydroxide dry powder (obtained through the above selection), acetic acid as a peptizer, scallop powder as an extrusion aid and deionized water according to the formula in Table 1, then knead, and extrude into strips, which are shaped like clover , then dried at 110°C for 3h, and calcined at 550°C for 3h to make the catalyst carrier S of the present invention 1 , the main physicochemical properties are shown in Table 2, and the catalyst carrier S1 was subjected to N 2 The shape of the hysteresis loop formed by its isotherm after the adsorption / desorption test is shown in Figure 1, and the shape of the hysteresis loop is similar to that of the B-type hysteresis loop.

example 2

[0026] The macroporous aluminum hydroxide dry powder selected above (obtained through the above selection), acetic acid as peptizer, scallop powder and deionized water as extrusion aid are mixed according to the formula in Table 1, then kneaded, and extruded into strips. It is clover-shaped, then dried at 100°C for 4h, and calcined at 500°C for 4h to make the catalyst carrier S of the present invention 2 , the main physicochemical properties are shown in Table 2, and the catalyst carrier S1 was subjected to N 2 After the adsorption / desorption test, the shape of the hysteresis loop formed by its isotherm is similar to that of accompanying drawing 1.

example 3

[0028] The macroporous aluminum hydroxide dry powder selected above (obtained through the above selection), acetic acid as peptizer, scallop powder and deionized water as extrusion aid are mixed according to the formula in Table 1, then kneaded, and extruded into strips. It is clover-shaped, then dried at 130°C for 2h, and calcined at 550°C for 2h to make the catalyst carrier S of the present invention 3 , the main physicochemical properties are shown in Table 2, and the catalyst carrier S1 was subjected to N 2 After the adsorption / desorption test, the shape of the hysteresis loop formed by its isotherm is similar to that of accompanying drawing 1.

[0029] 3. Preparation of co-immersion solution

[0030] Add WO to 120ml deionized water 3 65g of ammonium metatungstate with a total content of 82.0%, 35g of nickel nitrate and 10ml of orthophosphoric acid were stirred and dissolved and filtered to obtain a co-immersion solution containing W, Ni, and P elements, and deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com