Machine-woven industrial filter cloth of covered yarns and production and application thereof

A technology of covering yarn and filter cloth, which is used in textiles, papermaking, fabrics, textiles, etc., can solve the problems of poor filter cloth decake effect, low filtration accuracy, shortened filter cloth service life, etc. , The effect of improving filtration precision and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

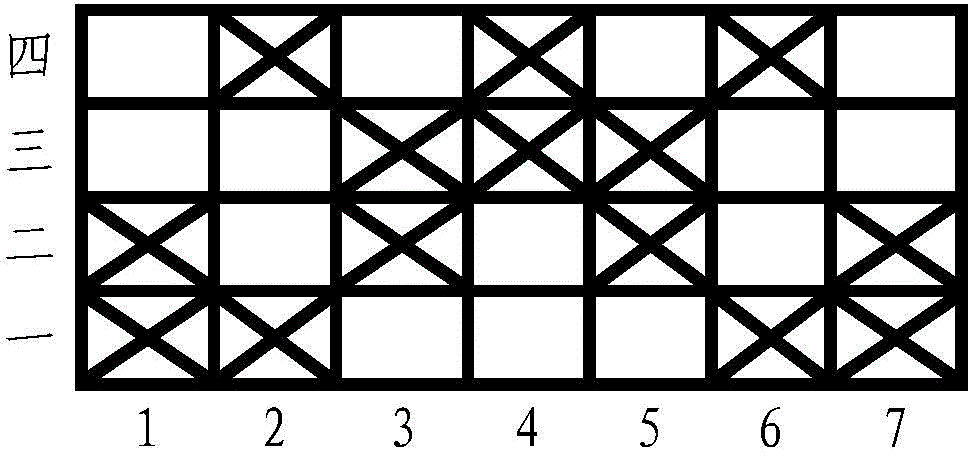

[0031] The woven filter cloth used in the field of solid-liquid separation requires the fabric to be stiff and stable, not easy to wrinkle and fold, and the filter residue can adhere to the surface of the fabric without falling off or passing through the filter (see Table 1).

[0032] 1. Preparation of woven industrial filter cloth:

[0033] The woven filter cloth is woven from warp yarns and weft yarns, and has a mountain-shaped twill structure. The warp yarns are 2 Φ0.15 monofilaments and 1 1000D multifilament twisted; the weft yarns are 3 Φ0.25 monofilaments and 1300D multifilaments. Composed of covered yarn.

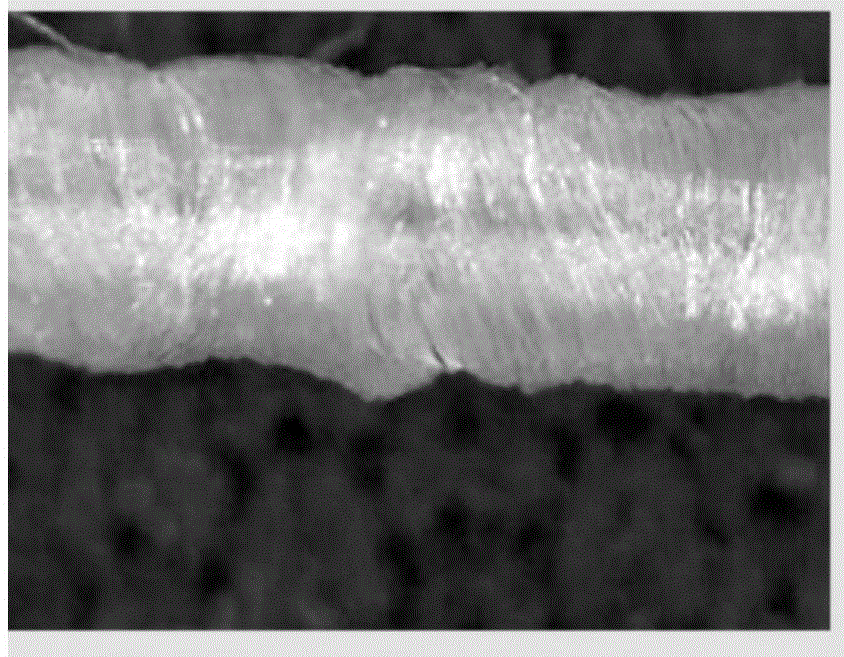

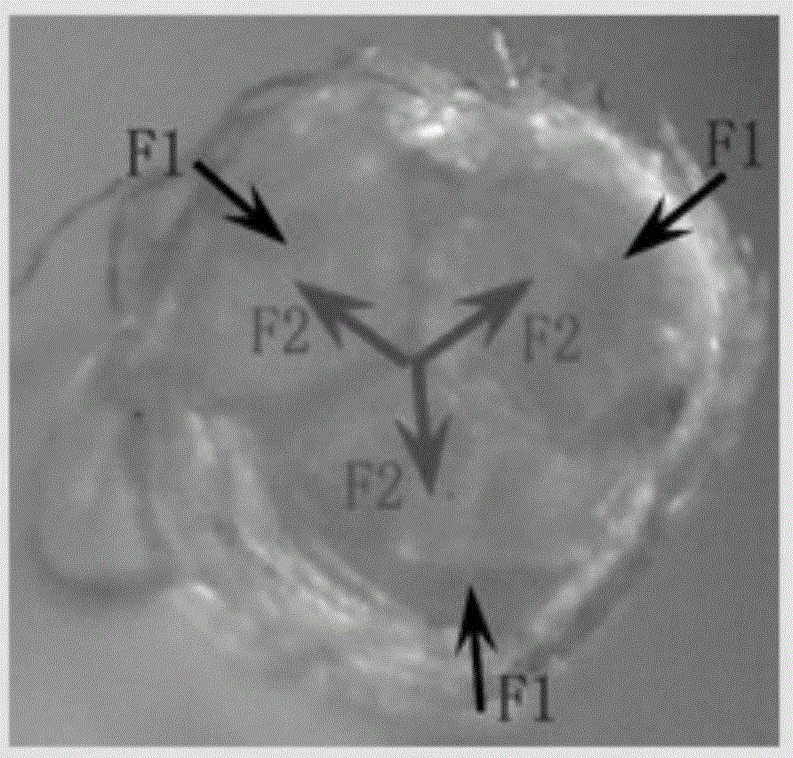

[0034] Covered yarn is composed of core yarn and outer yarn. Its production process is mainly formed by continuously rotating the outer yarn and winding it on the core yarn that is drafted at a constant speed (see figure 1 and figure 2 ).

[0035] Depend on figure 1 It can be seen that the outer layer of the covered yarn is tightly and evenly wrapped by multifil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com