Air pressure cloth inspecting machine

A cloth inspection machine and air pressure technology, which is applied in the inspection of textile materials, textiles and papermaking, etc., can solve the problems of easy respiratory infection, inability to inspect cloth efficiently, high error rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

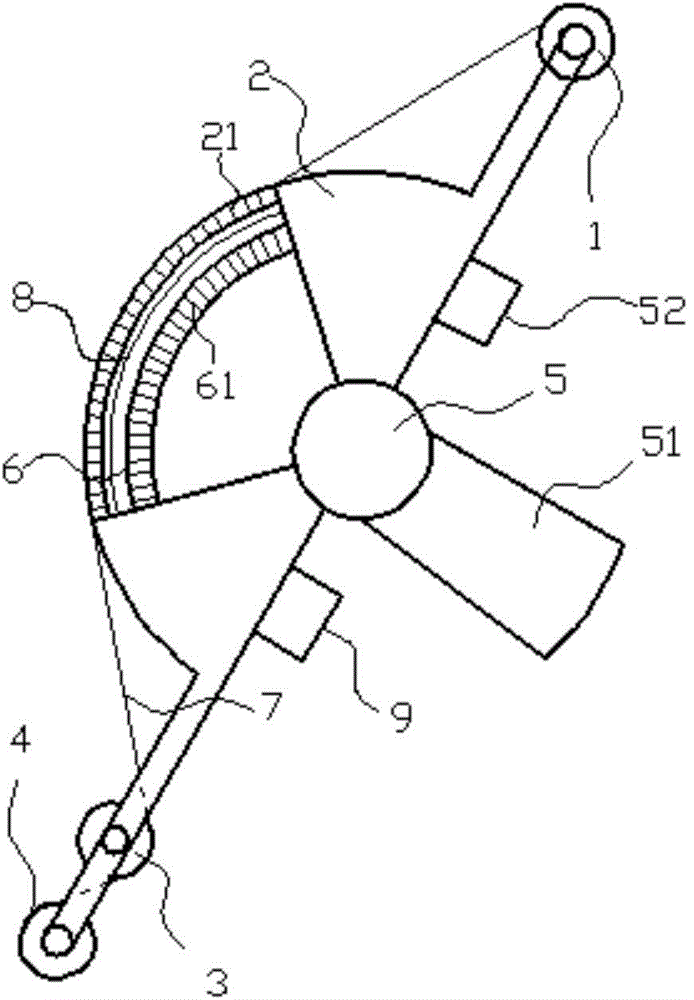

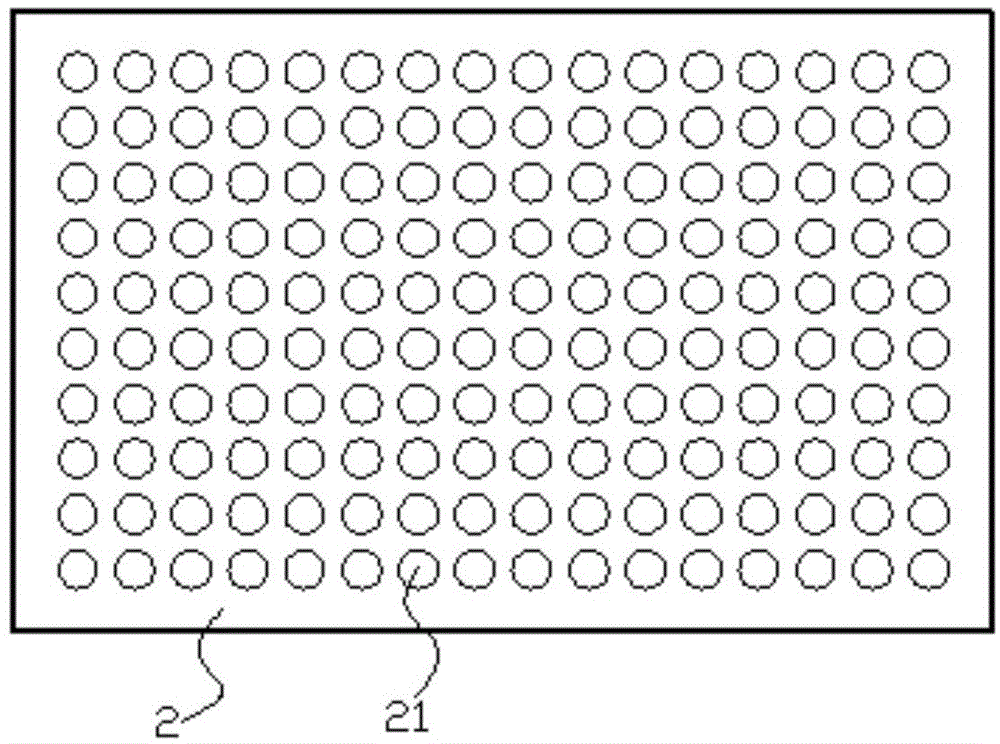

[0012] exist figure 1 , figure 2 In the illustrated embodiment, the air pressure cloth inspection machine mainly includes a loose cloth rotating shaft 1, a workbench 2, a driving roller 3 and a cloth rolling shaft 4; the loose cloth rotating shaft 1 is installed on the top of the workbench 2, and the cloth rolling The rotating shaft 4 is installed at the bottom of the workbench 2, and the surface of the driving roller 3 is rough and maintains static friction with the cloth 7; Stomach 21, the axis of each described ventilation hole 21 is vertical and points to the axis of described arched surface; Observe from the expanded view of the arched surface of workbench 2, as figure 2 As shown, the ventilation holes 21 are distributed equidistantly and vertically on the workbench 2 and form a rectangular array; a detection module 6 is installed below the workbench 2, and each air pressure detection end 61 on the detection module 6 is One-to-one matching with each of the air holes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com