Outdoor sportswear fabric and preparation method thereof

A technology for sportswear and fabrics, applied in the field of fabrics, which can solve the problems of difficulty in cleaning clothes, reducing the air permeability of fabrics, ignoring the comfort of clothing, etc., achieve good antibacterial, anti-ultraviolet and waterproof effects, improve wearing performance, and ensure wearing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An outdoor sportswear fabric comprises a surface layer coating, a middle layer fabric and an inner layer fabric. The inner fabric is made of blended superfine polyester fiber, bamboo fiber and Coolplus fiber, wherein the weight percentage of superfine polyester fiber is 50%, the weight percentage of bamboo fiber is 15%, and the weight percentage of Coolplus fiber is 35%. The middle layer fabric is made of a blend of superfine polyester fiber, Coolplus fiber and cupro fiber, wherein the weight percentage of superfine polyester fiber is 65%, the weight percentage of Coolplus fiber is 15%, and the weight percentage of cupro fiber is 20%; The surface coating is polyurethane waterproof coating.

[0036] The ultra-fine polyester fiber of the middle layer fabric will undergo antibacterial and anti-ultraviolet treatment.

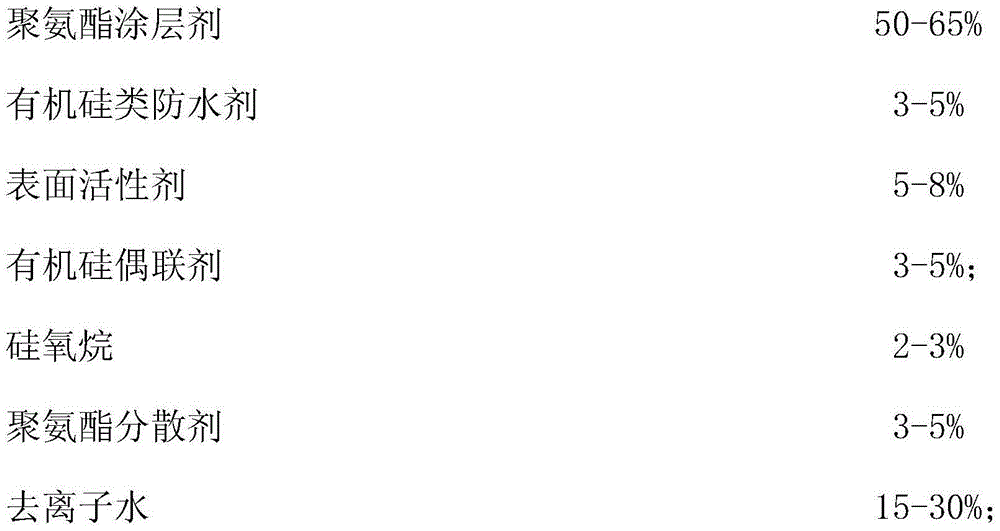

[0037] Described antibacterial antiultraviolet treatment agent comprises the component of following weight percent:

[0038]

[0039] Preferably, the po...

Embodiment 2

[0054] An outdoor sportswear fabric comprises a surface layer coating, a middle layer fabric and an inner layer fabric. The inner fabric is made of blended superfine polyester fiber, bamboo fiber and Coolplus fiber, wherein the weight percentage of superfine polyester fiber is 55%, the weight percentage of bamboo fiber is 10%, and the weight percentage of Coolplus fiber is 35%. The middle layer fabric is made of a blend of superfine polyester fiber, Coolplus fiber and cupro fiber, wherein the weight percentage of superfine polyester fiber is 75%, the weight percentage of Coolplus fiber is 10%, and the weight percentage of cupro fiber is 15%; The surface coating is polyurethane waterproof coating.

[0055] The ultra-fine polyester fiber of the middle layer fabric will undergo antibacterial and anti-ultraviolet treatment.

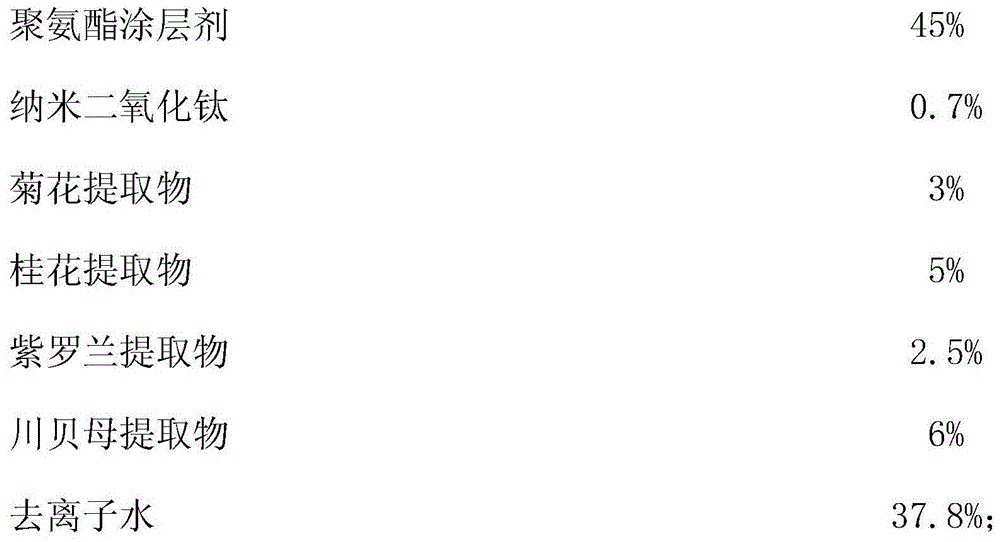

[0056] Described antibacterial antiultraviolet treatment agent comprises the component of following weight percent:

[0057]

[0058] Preferably, the po...

Embodiment 3

[0073] An outdoor sportswear fabric comprises a surface layer coating, a middle layer fabric and an inner layer fabric. The inner fabric is made of blended superfine polyester fiber, bamboo fiber and Coolplus fiber, wherein the weight percentage of superfine polyester fiber is 40%, the weight percentage of bamboo fiber is 20%, and the weight percentage of Coolplus fiber is 40%. The middle layer fabric is made of a blend of superfine polyester fiber, Coolplus fiber and cupro fiber, wherein the weight percentage of superfine polyester fiber is 65%, the weight percentage of Coolplus fiber is 10%, and the weight percentage of cupro fiber is 25%; The surface coating is polyurethane waterproof coating.

[0074] The ultra-fine polyester fiber of the middle layer fabric will undergo antibacterial and anti-ultraviolet treatment.

[0075] Described antibacterial antiultraviolet treatment agent comprises the component of following weight percent:

[0076]

[0077] Preferably, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com