Energy-saving and environment-friendly oil-stone separation production device for road old asphalt mixture

An energy-saving and environment-friendly production device technology, applied in the direction of roads, roads, road repairs, etc., can solve the problem of high temperature, solvent dosage, and soaking time control, and cannot achieve the effect of mass processing of old asphalt materials, energy, raw materials, Solve problems such as artificial waste, achieve the effect of improving the oil-stone separation effect, improving the oil-stone separation effect, and smooth feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

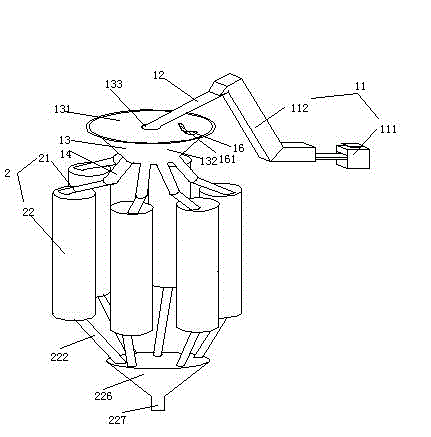

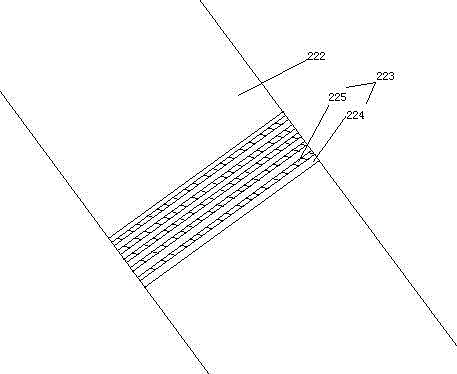

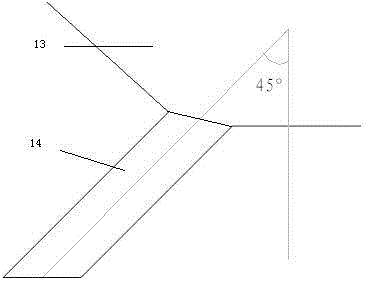

[0017] As shown in the figure, an energy-saving and environment-friendly road-used asphalt mixture oil stone separation production device includes a feeding device 1 and a separation device 2, and the feeding device 1 includes a conveying device 11, a feed pipeline 12, and a hopper 13. And feeding pipeline 14, the delivery device 11 includes a conveyor 111 and a delivery pipeline 112, the delivery pipeline 112 is arranged outside the conveyor 111, the hopper 13 is funnel-shaped, and the upper end of the hopper 13 is provided with a cover plate 131, the cover plate 131 is connected to the hopper 13 by welding, the cavity surrounded by the cover plate 131 and the hopper 13 is the hopper cavity 132, the cover plate 131 is circular, and the center of the circular shape of the cover plate 131 is opened with a hole To the feeding port 133 of the hopper cavity 132, the lower end of the hopper 13 is evenly and symmetrically provided with 16 feeding pipes 14, the feeding pipes 14 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com