Oil cylinder with mechanical locking function and hydraulic system

A mechanical locking and functional technology, applied in the field of hydraulic pressure, can solve the problems of the oil cylinder lifting position not falling, the oil cylinder lifting position falling, and zero leakage can not be achieved, so as to avoid leakage, avoid hydraulic oil compression, and keep it from falling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

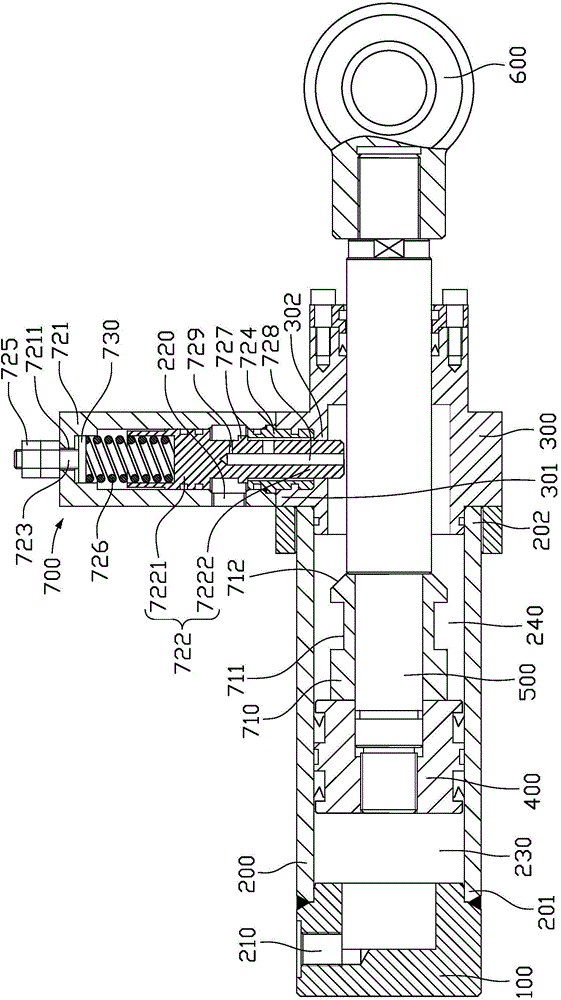

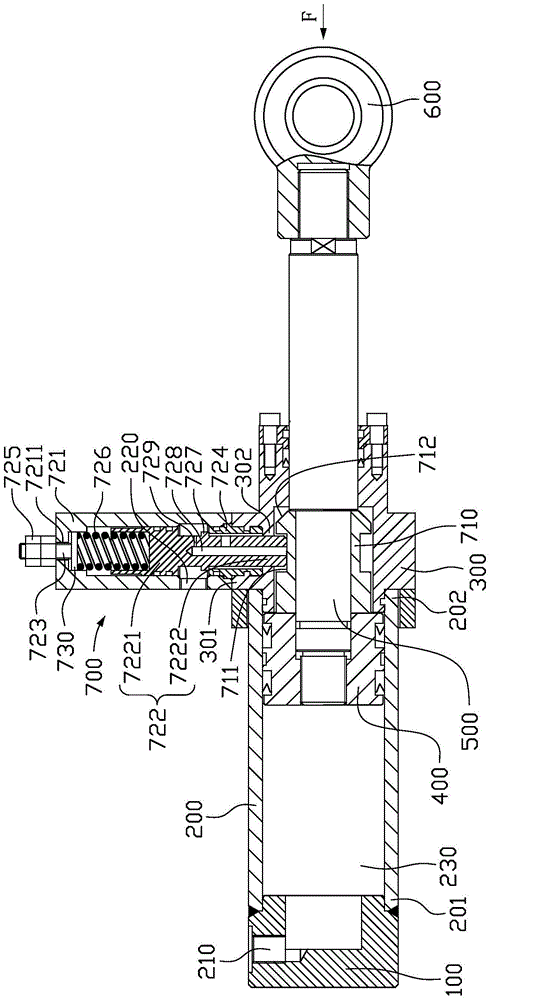

[0023] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended invention purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

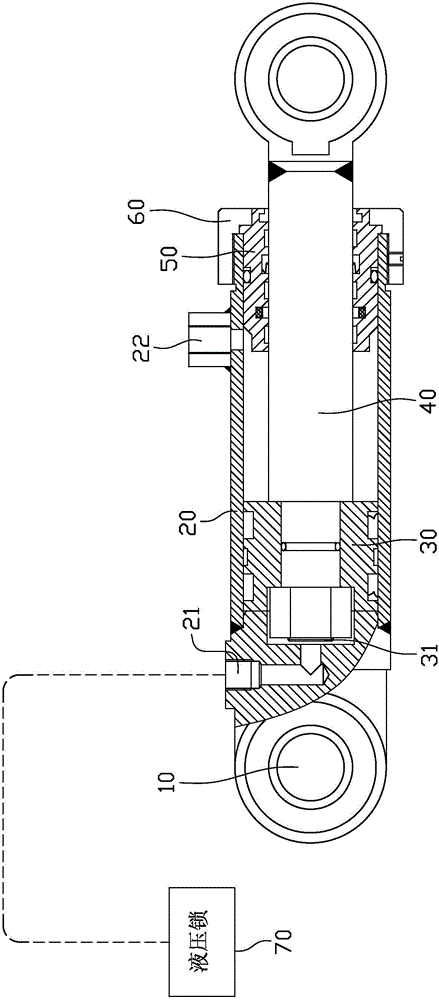

[0024] figure 2 It is a structural schematic diagram of an oil cylinder with a mechanical locking function in an embodiment of the present invention, as figure 2 As shown, the oil cylinder includes a cylinder head 100 , a cylinder barrel 200 , a cylinder head 300 , a piston 400 , a piston rod 500 , a front earring 600 and a piston rod locking device 700 . The piston 400 is mounted on one end of the piston rod 500 extending into the cylinder 200. The cylinder 200 has an opposite first end 201 and a second end 202. The cylinder 200 is formed between the piston 400 and the first end 201 of the cylinder 200. Without the rod chamber 230 , a rod chamber 240 is formed in the cylinder 200 between the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com