Multi-channel high-pressure gas mechanical reversing mechanism

A technology of high-pressure gas and mechanical reversing, applied in the direction of mechanical equipment, multi-way valves, valve housing structures, etc., can solve the problems of difficult maintenance, reduced work efficiency, expensive maintenance costs, etc., to avoid failures, simple structure, easy to use The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

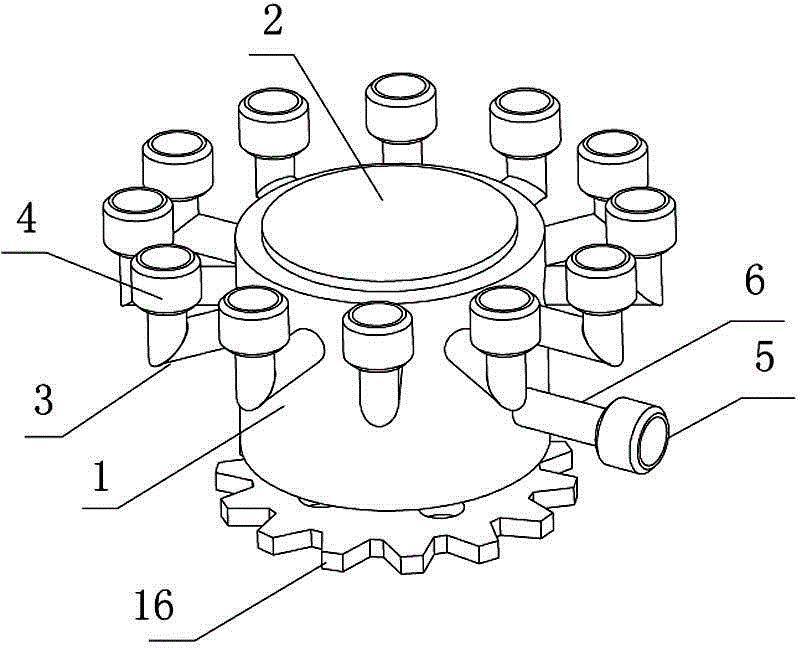

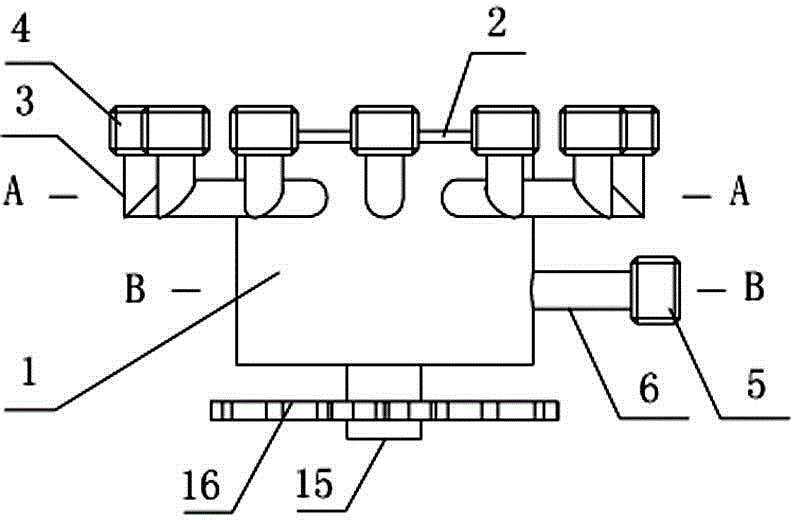

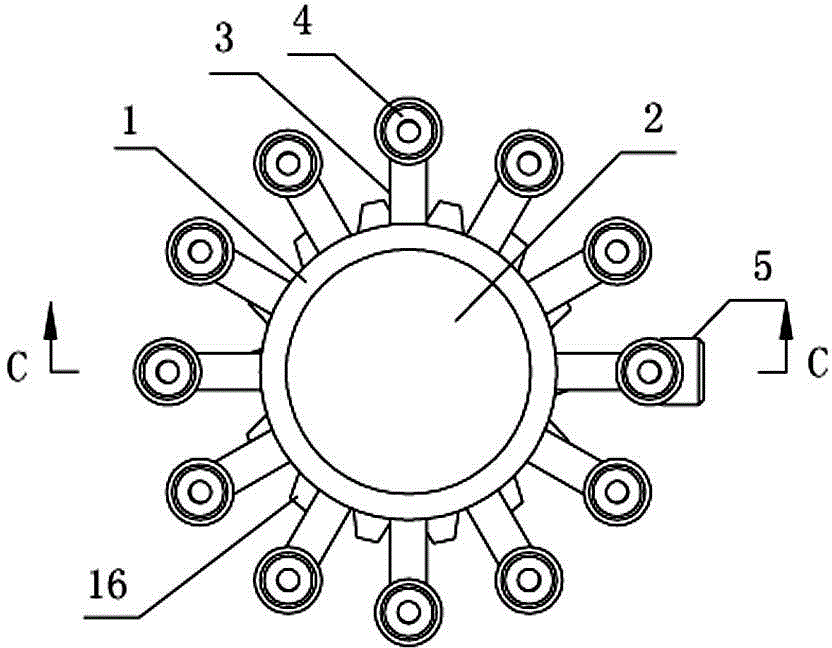

[0015] Such as Figure 1-6 As shown, the multi-channel high-pressure gas mechanical reversing mechanism of the present invention includes a valve casing 1 with a cylindrical cavity, and a cylindrical valve core 2 inserted in the cylindrical cavity of the valve casing 1; The upper part of the outer peripheral surface of the valve housing 1 is evenly distributed along the circumferential direction with twelve air outlets, and each of the air outlets is fixedly connected with an air outlet pipe 3 with an L-shaped structure, and the air outlet of the L-shaped air outlet pipe 3 is set upwards. And a pipe joint 4 is installed; the lower part of the outer peripheral surface of the valve housing 1 is provided with an air inlet, and the air inlet is fixedly connected with an air inlet pipe 6 with a pipe joint 5; the outer peripheral surface of the cylindrical valve core 2 is from top to bottom. There are three annular grooves 7, 8, 9 separated at the lower part, and sealing rings are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com