Real-time monitoring method of electric actuator of large valve

An electric actuator, real-time monitoring technology, applied to engine components, valve operation/release devices, valve details, etc., can solve the problem of shortening the service life of valves, aggravating the wear of valve core and valve inner cavity, and protecting the process of inability to travel, etc. problems, to avoid major accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

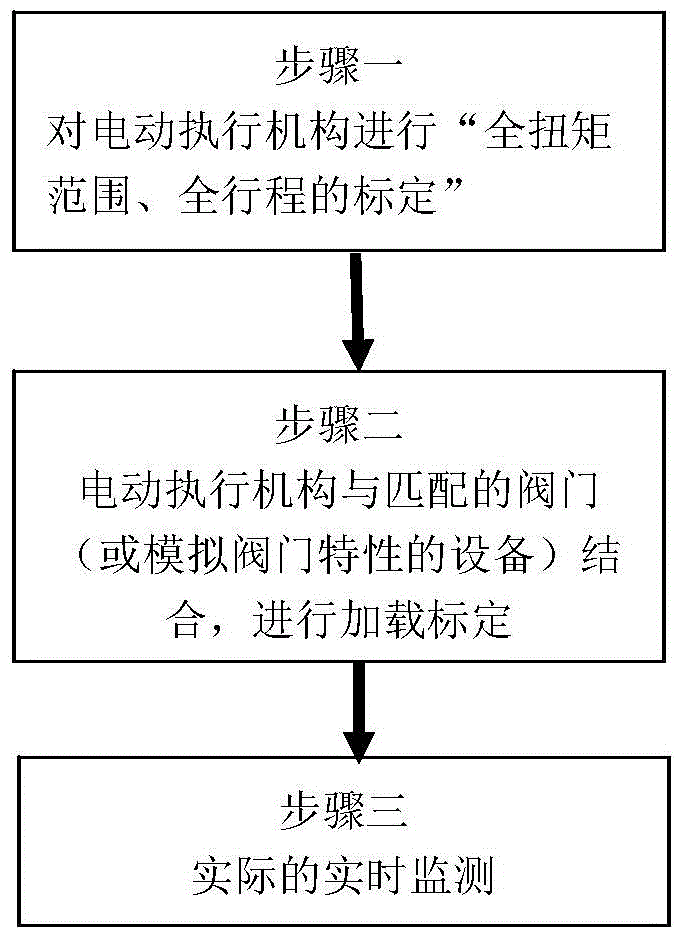

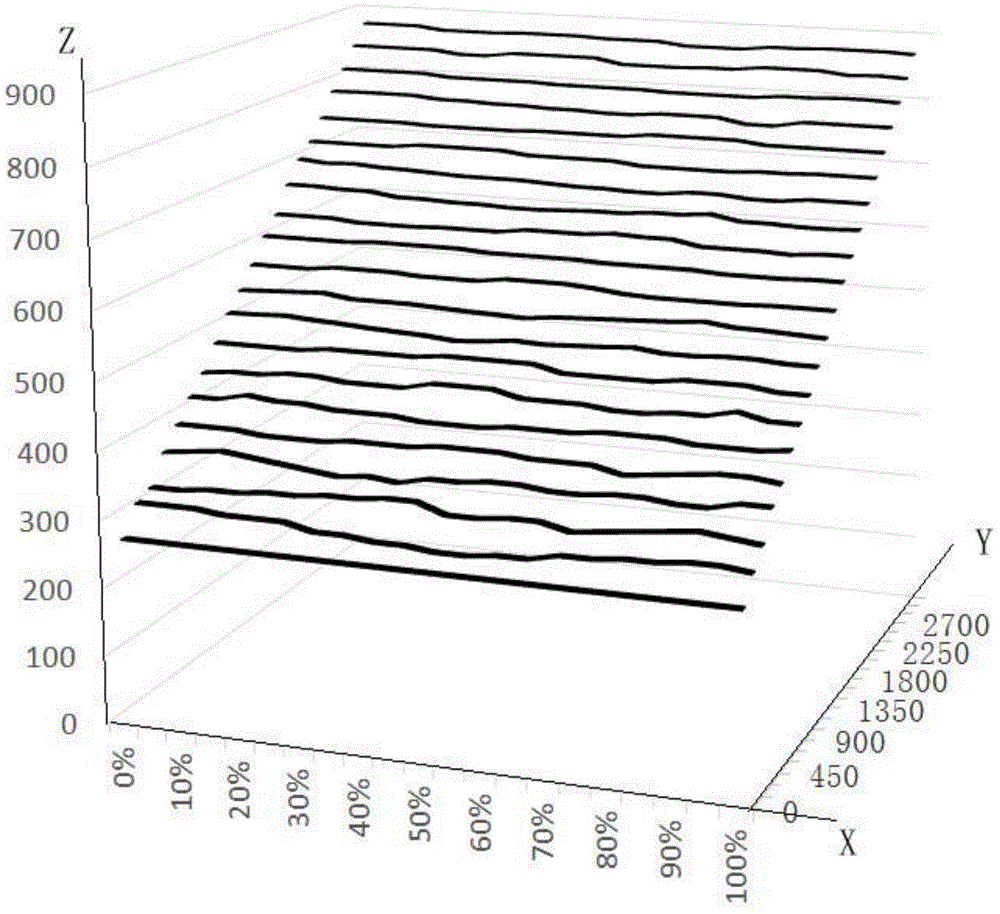

[0029] figure 1 It is a schematic flow diagram of the main steps of the present invention, such as figure 1 As shown, in step 1, firstly carry out "full torque range and full stroke calibration" on the electric actuator to obtain the following figure 2 The data table of "actual output torque value & stroke value --- analog-to-digital conversion value" shown is a three-dimensional data table.

[0030]

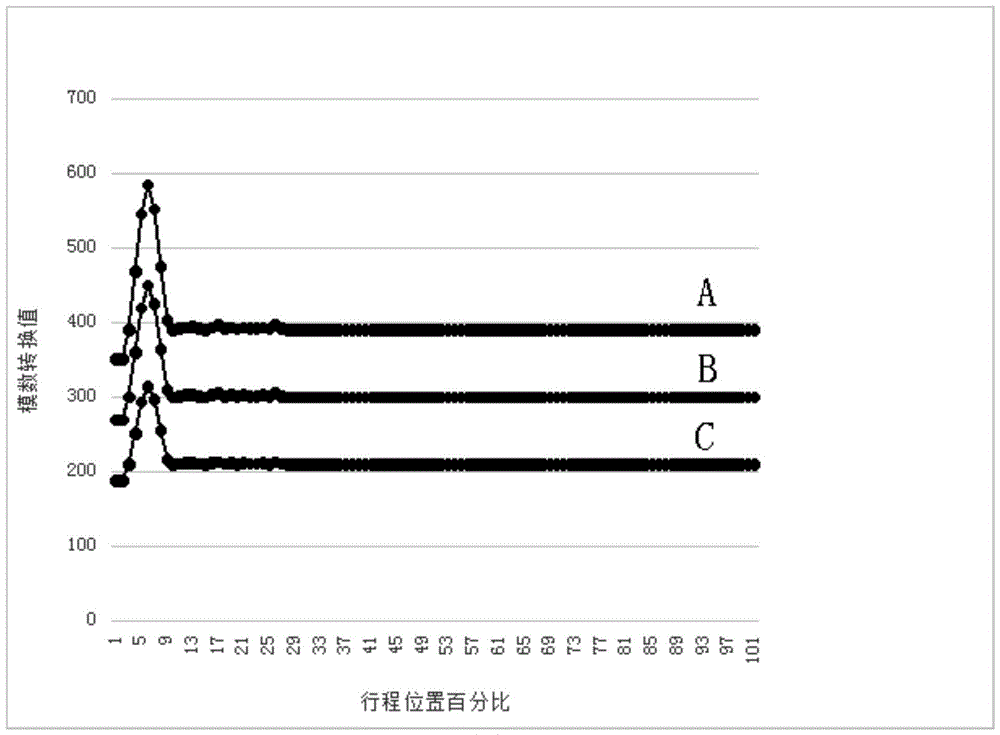

[0031] In this step, while performing range calibration on the analog-to-digital conversion value corresponding to the actual output torque value, the identification of the corresponding stroke position is added. Therefore, each actual stroke position and actual torque corresponds to an analog-to-digital conversion value, forming a Three-dimensional data table, the specific method is given as an example: starting from 0% of the rated torque, the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com