Multistage expansion pressure oil pipe

A technology of pressure oil pipe and pipe section, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of inability to flush and cool the workpiece, and inability to transmit pressure oil, achieve high practical value, meet the needs of use, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

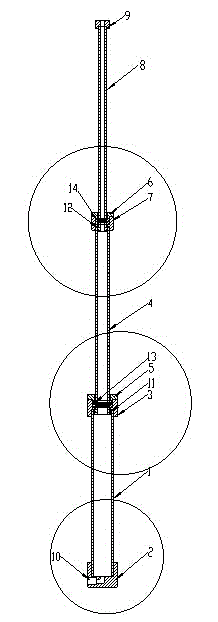

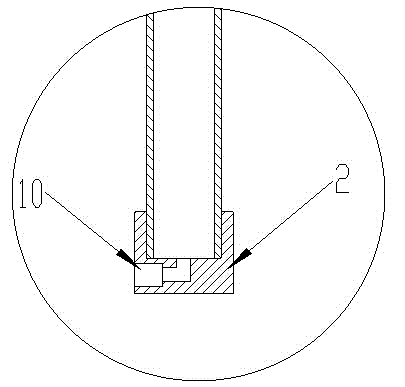

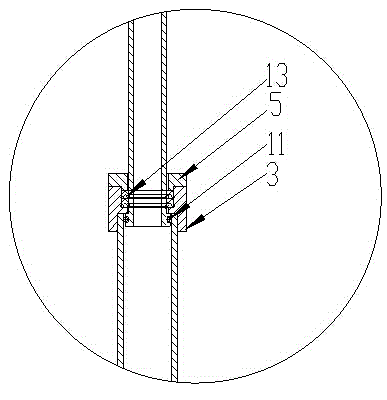

[0015] as attached Figure 1-4 The shown multi-stage telescopic pressure oil pipe of the present invention includes a large-section pipe 1, a large-section base 2, a large-section sleeve 3, a middle-section pipe 4, a large-section flange 5, a middle-section flange 6, a middle-section The joint sleeve 7, the small joint pipe 8, and the small joint sleeve 9; the large joint base 2 is provided at the lower end of the large joint pipe 1; the large joint base 2 is provided with a flow hole 10 communicating with the large joint pipe 1; the large joint The upper end of the pipe 1 is provided with a large-section sleeve 3; the middle-section pipe 4 is arranged in the large-section pipe 1 through the large-section sleeve 3; the upper end of the large-section sleeve 3 is also provided with a large-section flange 5; the middle-section pipe The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com