Single-cooling type refrigeration device and heating and cooling type refrigeration device

A refrigeration device, cooling and heating technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems affecting the heat exchange efficiency of heat exchangers, affecting the performance of compressors, etc., so as to improve sealing and lubrication performance and prolong service life Longevity, improved energy efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

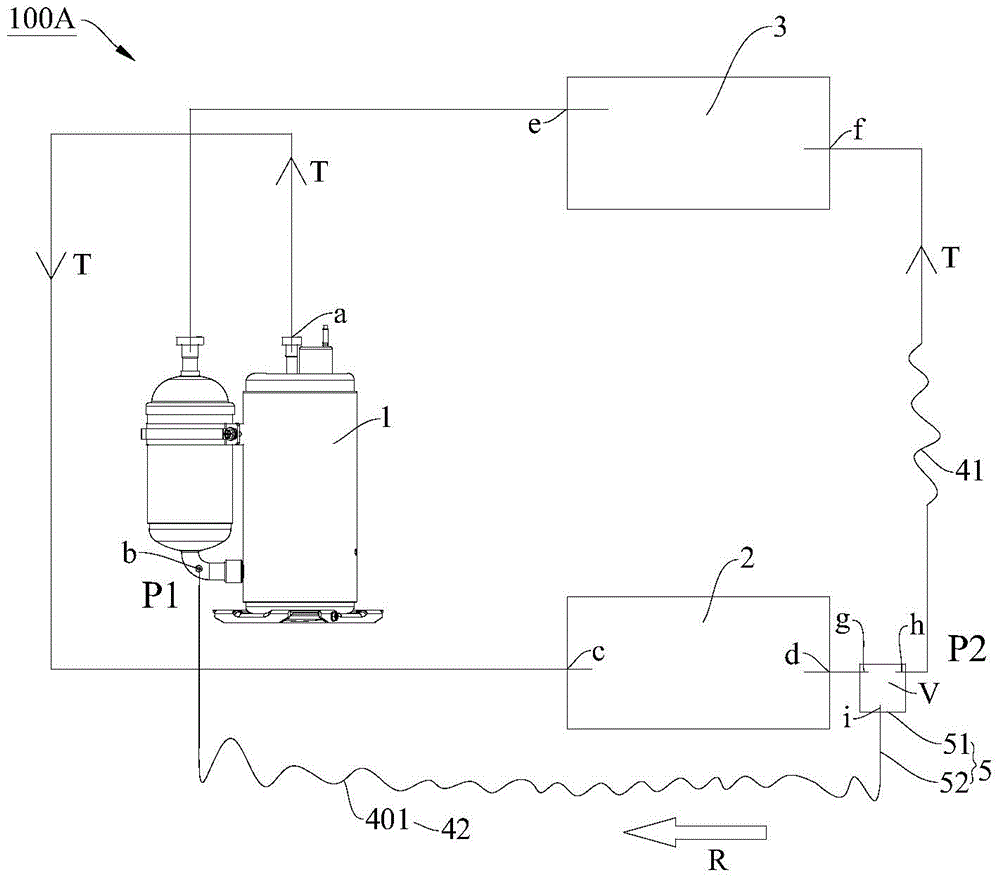

[0062] In this example, as figure 1 As shown, a second throttling element 42 is connected in series between the oil outlet i and the suction port b, that is, the second throttling element 42 is connected in series on the oil return pipe 52, thereby reducing the flow from the oil outlet i to the suction When the oil reaches the suction port b, the pressure will not be too high, so as to prevent the oil from affecting the quality and pressure of the refrigerant entering the compressor 1 from the indoor heat exchanger 3.

[0063] Specifically, in the refrigerant circulation channel T, during the process of the refrigerant flowing out from the refrigerant outlet h to the suction port b through the indoor heat exchanger 3, the refrigerant will have a certain pressure loss. The internal pressure of V is P2, and the pressure at the suction port b of the compressor 1 is P1, then P2>P1. In order to ensure that the refrigerated oil can smoothly flow to the suction port b through the oi...

no. 2 example

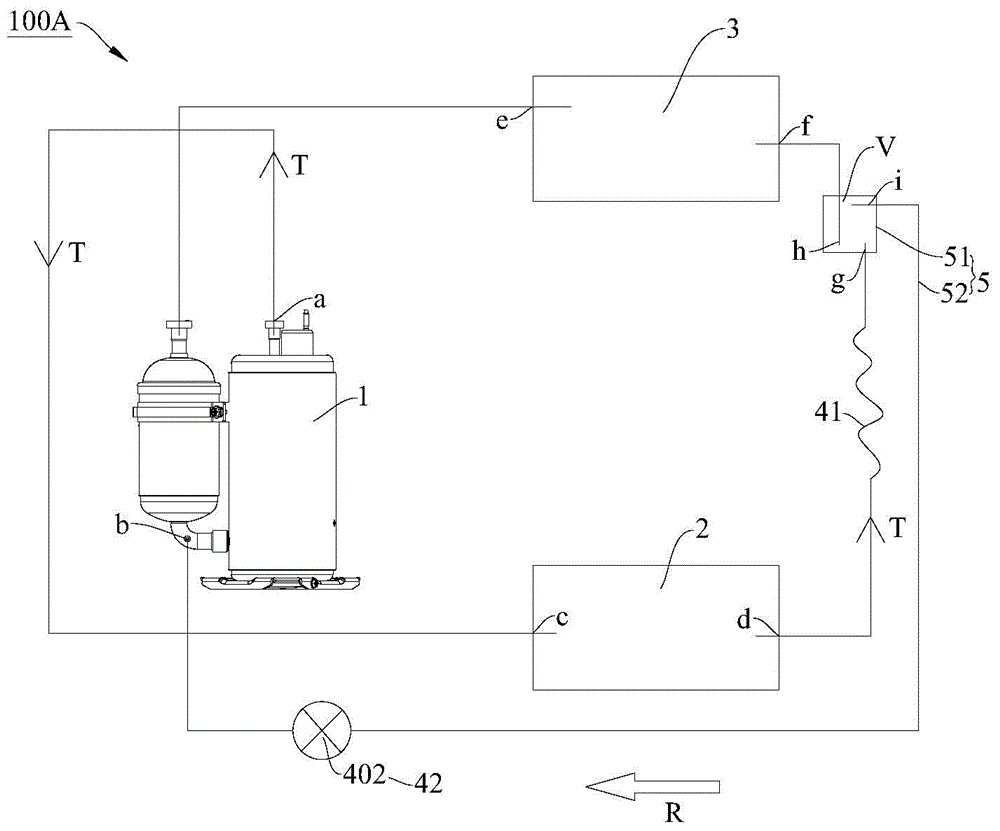

[0072] In the second embodiment, as figure 2 As shown, the structure of the single-cooling type refrigerating apparatus 100A is basically the same as that of the single-cooling type refrigerating apparatus 100A in the first embodiment, which will not be repeated here.

[0073] The difference is that in the second embodiment, the second throttle element 42 is an electronic expansion valve 402 . That is, the oil return device 5 performs oil return and pressure drop through the electronic expansion valve 402 . Of course, the second throttling element 42 may also adopt other pressure reducing elements, which are not specifically limited here.

[0074] It can be seen from the second embodiment that the arrangement of the inlet g and the refrigerant outlet h is not limited to being connected in series between the outdoor heat exchanger 2 and the first throttling element 41, and the inlet g and the refrigerant outlet h can also be connected in series between the indoor heat exchang...

no. 3 example

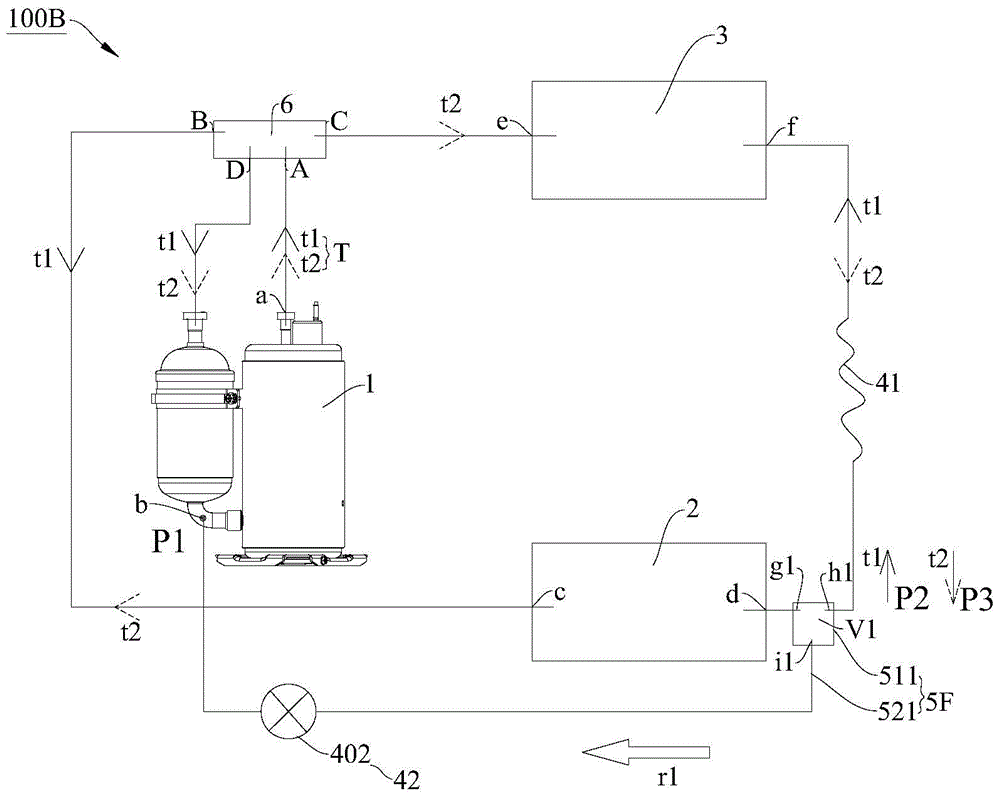

[0093] In this example, as image 3 As shown, a second throttle element 42 is connected in series between the first oil outlet i1 and the suction port b. In this way, the pressure of the oil flowing from the first oil outlet i1 to the suction port b can be reduced, and the pressure will not be too high when the oil reaches the suction port b, thereby preventing the oil pair from entering the refrigerant circulation passage T into compression The quality and pressure of the refrigerant inside the unit 1 are affected.

[0094] In the third embodiment, the first inlet g1 and the first refrigerant outlet h1 are connected in series between the outdoor heat exchanger 2 and the first throttling element 41, that is, in the figure 1 , the first liquid separator 511 is connected in series between the outdoor heat exchanger 2 and the first throttling element 41 .

[0095] Advantageously, the second throttling element 42 is configured to adjust the amount of depressurization of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com