A visual inspection machine

An inspection machine and video technology, which is applied in the field of video inspection machines, can solve the problems of large equipment size, unsuitable adjustment, and difficult fixing of products, and achieve the effect of good verification results, high test consistency, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

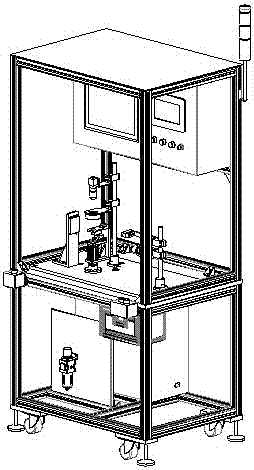

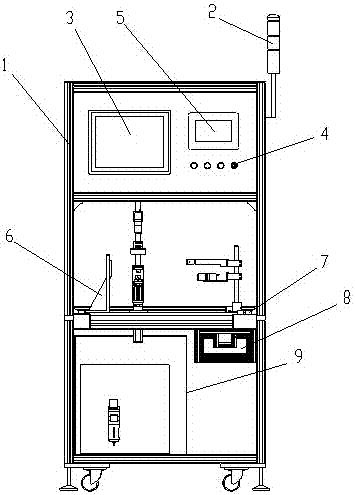

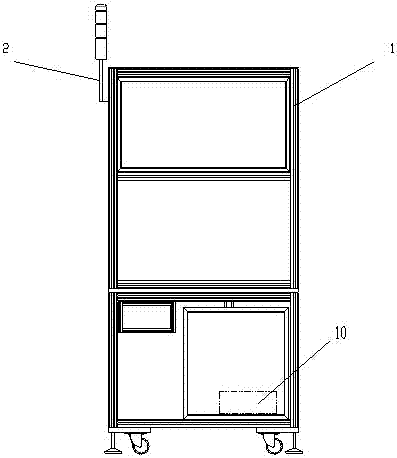

[0015] Such as Figure 1-4 As shown, a video inspection machine includes an aluminum profile frame 1, a button box 7, a defective product box 8, an electrical control box 9, a DMV controller 10, and a fixture assembly 6. Color indicator light 2, display 3, key switch 4 with indicator button, touch screen 5 are arranged on the inner upper part of aluminum profile frame 1; fixture assembly 6 is arranged on the inner middle part of frame 1; fixture assembly 6 includes servo motor 61, bearing Seat 62, clamping cylinder 63, linear lighting body 64, digital camera 65, ring lighting body 66, backlight lighting body 67, shell positioning cylinder 68, clamping cylinder 63 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com