Laser measurement device for centralization error

A laser measurement and error technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low precision, cumbersome operation, long time, etc., to improve measurement accuracy and resolution, high measurement accuracy, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

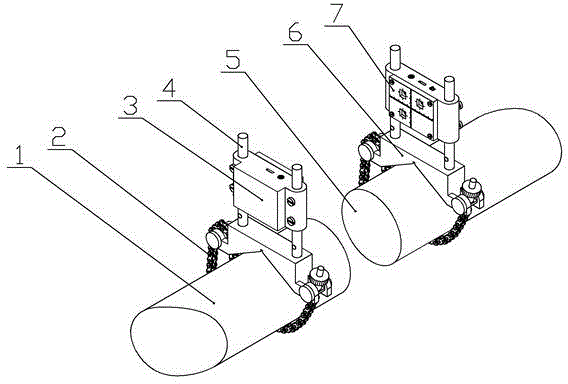

[0024] see figure 1 As shown, the present invention is made up of the first shaft to be measured 1, the laser emitting device 3, the second shaft to be measured 5 and the laser receiving device 7, the laser emitting device 3 is fixed on the first shaft to be measured 1, and the laser receiving device 7 fixed on the second axis 5 to be measured;

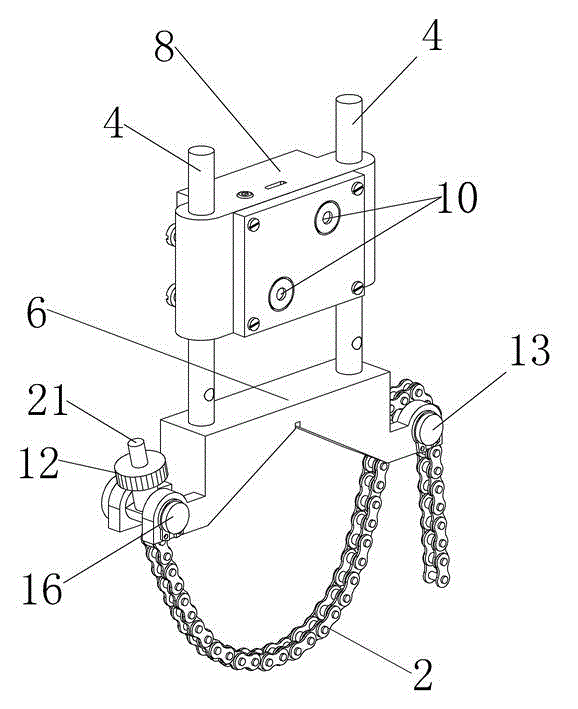

[0025] see image 3 and Figure 4 As shown, the laser emitting device 3 is composed of a locking chain 2, a fixed rod 4, a V-shaped block 6, a transmitter housing 8, a battery 9, a laser 10, a transmitter housing cover 11, a knurled nut 12, a A pin shaft 13, buckle 14, retaining ring 15 and second pin shaft 16 are composed, the battery 9 and two lasers 10 are fixed on the transmitter housing 8 by screws, the axes of the two lasers 10 are all horizontal, and the transmitter housing There is a power switch and a charging interface on the body 8, and the emitter shell cover 11 is fixed on the emitter shell 8 by screws to form a packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com