Fault diagnosing and positioning method for four position sensors of four-phase switch reluctance motor

A switch reluctance motor, sensor failure technology, applied in instruments, measuring devices, etc., can solve the problems of position sensor output signal edge pulse loss, switched reluctance motor commutation failure, inapplicability and other problems, to achieve a wide range of engineering application value, The diagnostic method is reliable and the effect of avoiding misdiagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

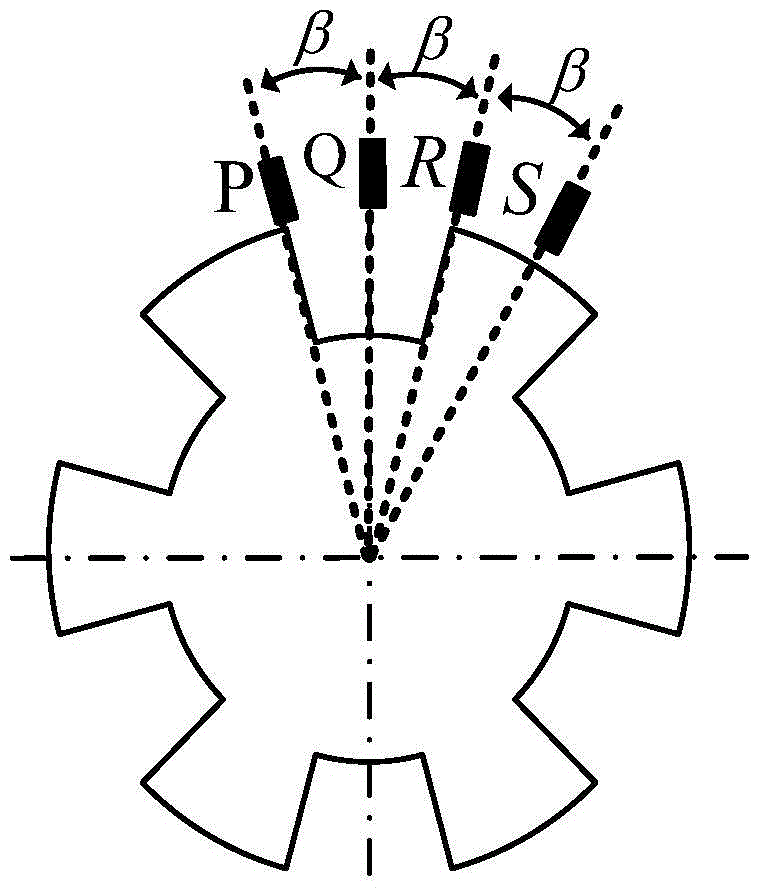

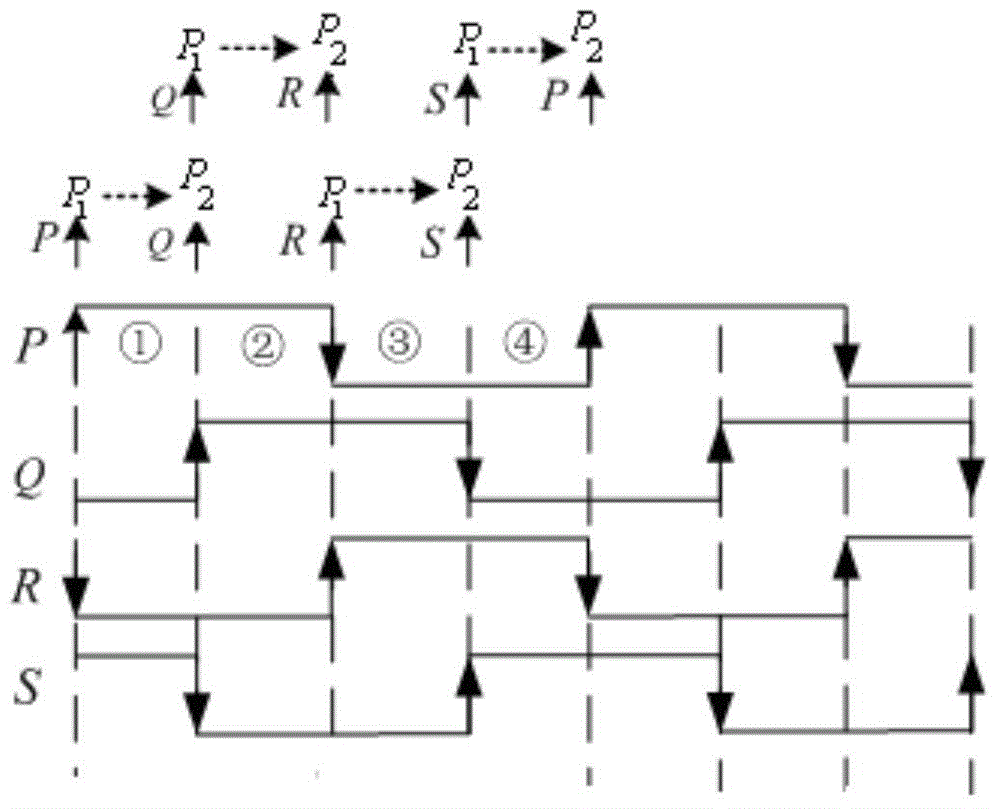

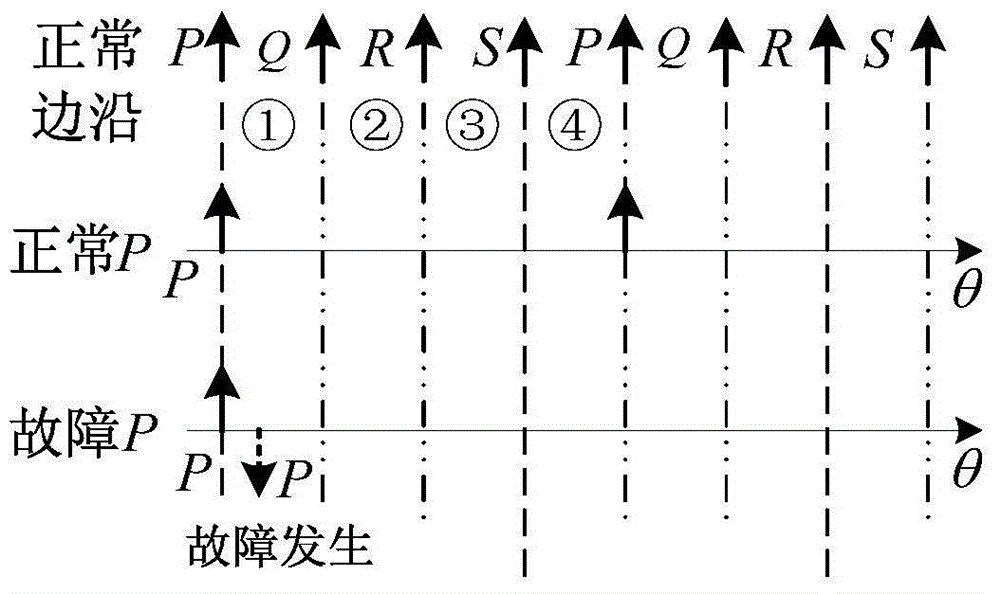

[0040] figure 1 Shown is a schematic diagram of the installation of four position sensors P, Q, R and S of a four-phase 8 / 6 structure switched reluctance motor. The output signal of the position sensor is as figure 2 As shown, the output signal phase of the switched reluctance motor position sensor P is earlier than the output signal phase of the position sensor Q, the output signal phase of the position sensor Q is earlier than the output signal phase of the position sensor R, and the position sensor R The output signal phase is earlier than the output signal phase of the position sensor S in time, and the output signal phase of the position sensor S is earlier than the output signal phase of the position sensor P; set the rising edge of the output signal of the position sensor P to the rising edge of the output signal of the position sensor Q The edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com