High-measuring-frequency magnetostriction sensor

A technology of magnetostriction and frequency measurement, which is applied in the direction of measuring devices, instruments, and the use of wave/particle radiation devices to transmit sensing components. drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

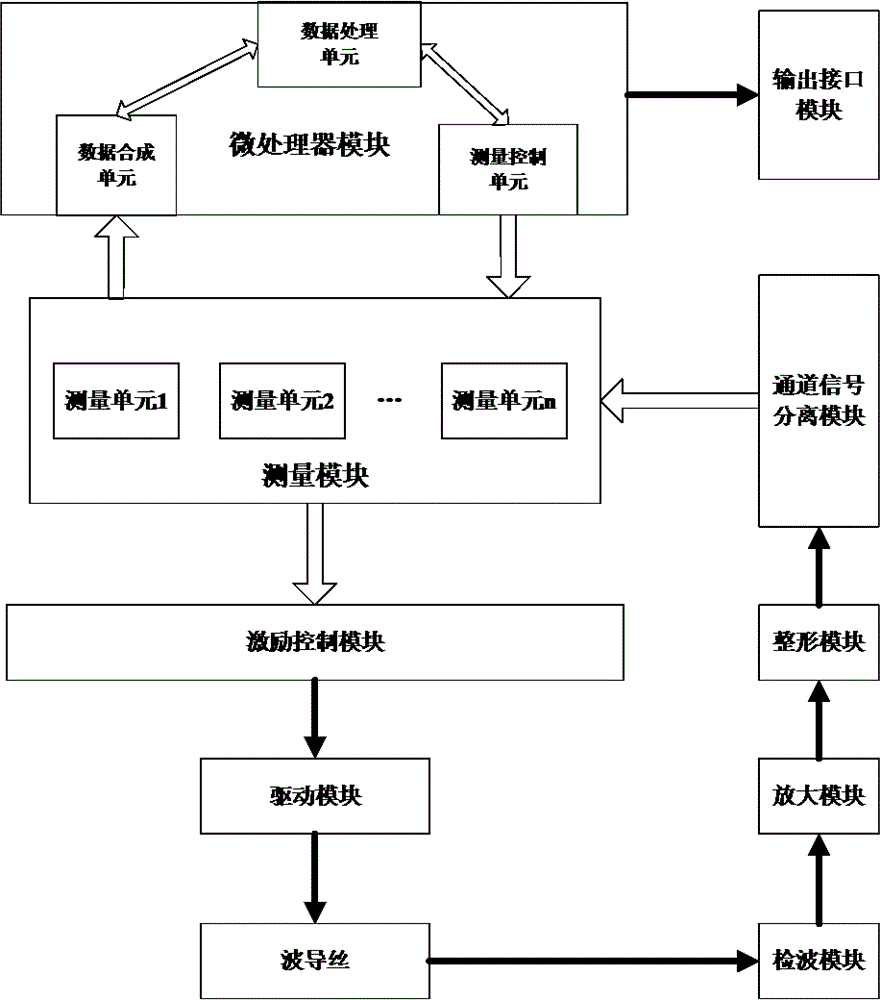

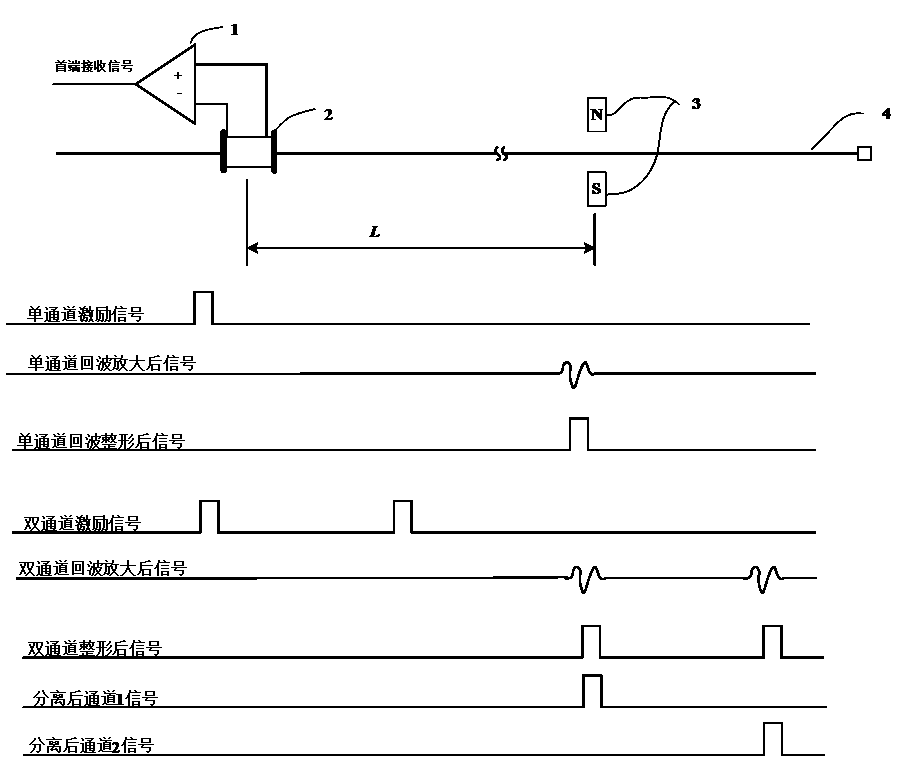

[0067] Embodiment 1: A magnetostrictive sensor with high measurement frequency, the sensor includes an electronic cabin, a measuring rod and a magnetic ring vernier, a waveguide wire is arranged in the measuring rod, and the electronic cabin includes a microprocessor module, a measurement module, and an excitation control module , a drive module, a detection module, an amplification module, a shaping module, a channel signal separation module and an output interface module. The microprocessor module is connected with the measurement module and the output interface module respectively; the measurement module is connected with the microprocessor module and the excitation control module respectively; the excitation control module is connected with the measurement module and the drive module respectively; the drive module is respectively connected with the excitation control module and the waveguide wire Connection; the waveguide wire is connected to the drive module and the wave d...

Embodiment 2

[0074] Embodiment 2: A magnetostrictive sensor with high measurement frequency, the sensor includes an electronic cabin, a measuring rod and a magnetic ring vernier, a waveguide wire is arranged in the measuring rod, and the electronic cabin includes a microprocessor module, a measurement module, and an excitation control module , a drive module, a detection module, an amplification module, a shaping module and an output interface module. The microprocessor module is connected with the measurement module and the output interface module respectively; the measurement module is connected with the microprocessor module and the excitation control module respectively; the excitation control module is connected with the measurement module and the drive module respectively; the drive module is respectively connected with the excitation control module and the waveguide wire connection; the waveguide wire is connected to the drive module and the wave detection module respectively; the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com