Superheat degree measurement method and device

A technology of measuring device and measuring method, applied in the direction of measuring device, measuring heat, using electric device, etc., can solve the problems of installation difficulty, measurement error, large error, etc., and achieve the effect of high precision, reliability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

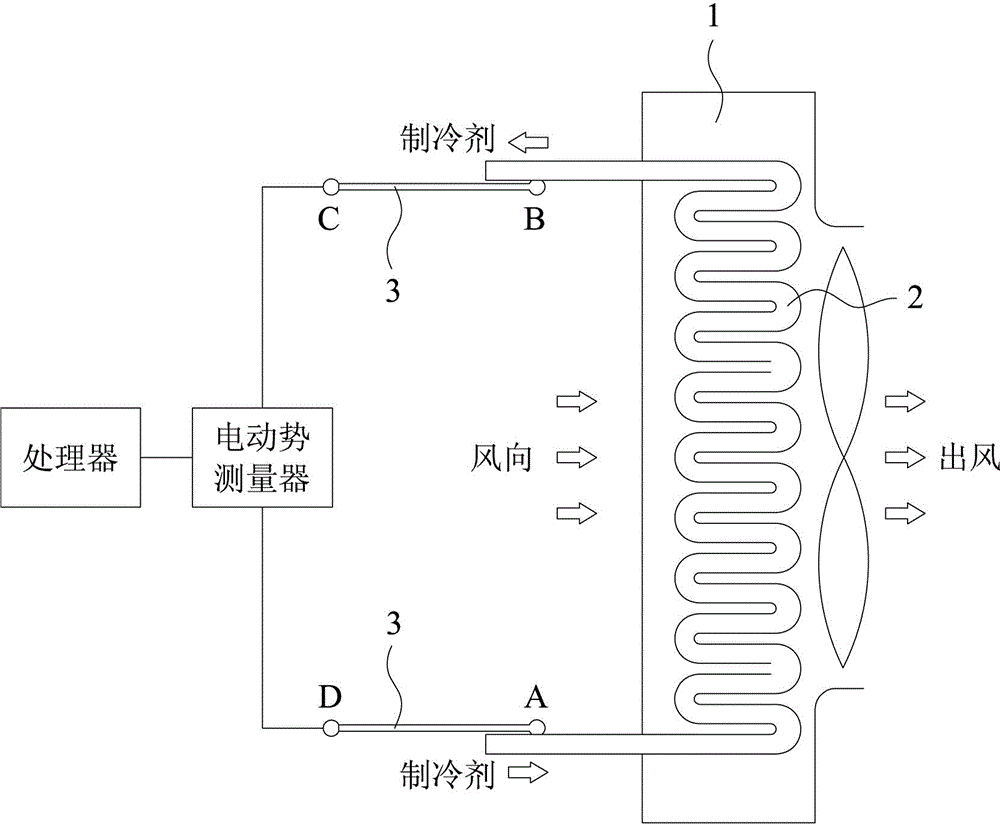

[0020] Embodiment 1: There is an evaporator 1 in the refrigeration cycle, and the evaporator 1 has an evaporator pipeline 2 through which the refrigerant flows. Usually, the evaporator pipeline 2 is a curved metal tube (such as a copper tube), and its two The ends are the inlet and outlet ends respectively and extend outside the evaporator 1 . Usually, the evaporator 1 is used to realize the superheat degree, an important parameter of the refrigeration system, which is used to measure the difference between the superheat temperature and the saturation temperature of the refrigerant in the refrigeration cycle.

[0021] A superheat measurement method for measuring superheat is realized based on the Seebeck effect. First, the electrodes 3 are respectively connected to the inlet and outlet ends of the evaporator pipeline 2. The electrodes 3 contain metal materials and are different from the material used in the evaporator pipeline 2. For example, the material of the electrode 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com