Stress detector calibration device

The technology of a calibration device and a stress gauge is applied in the field of the stress gauge calibration device, which can solve problems such as inconvenience and achieve the effects of reasonable accuracy, simplified structure, and guaranteed structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

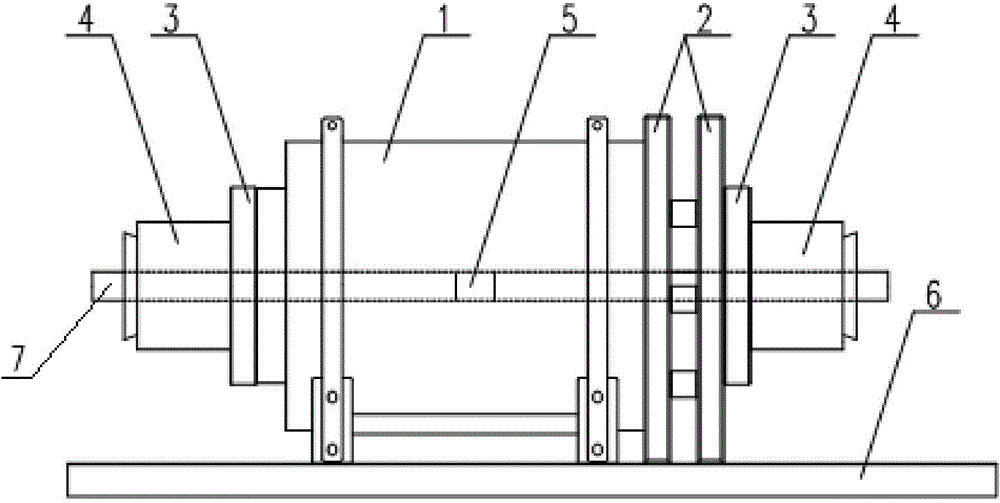

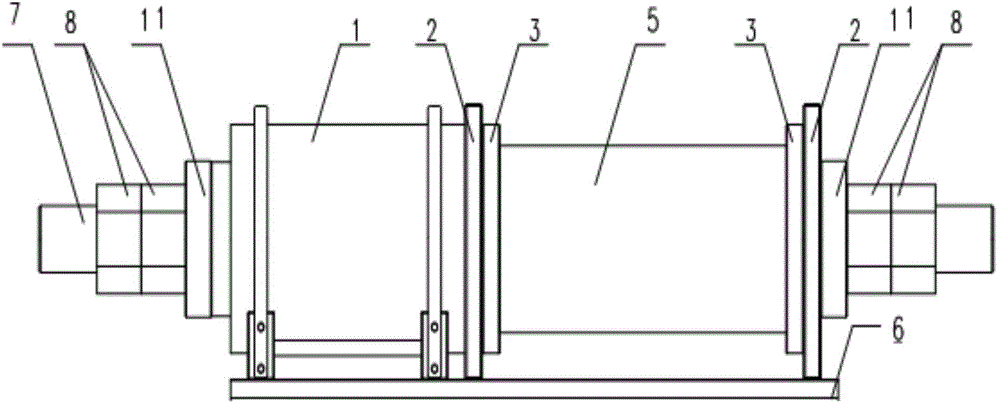

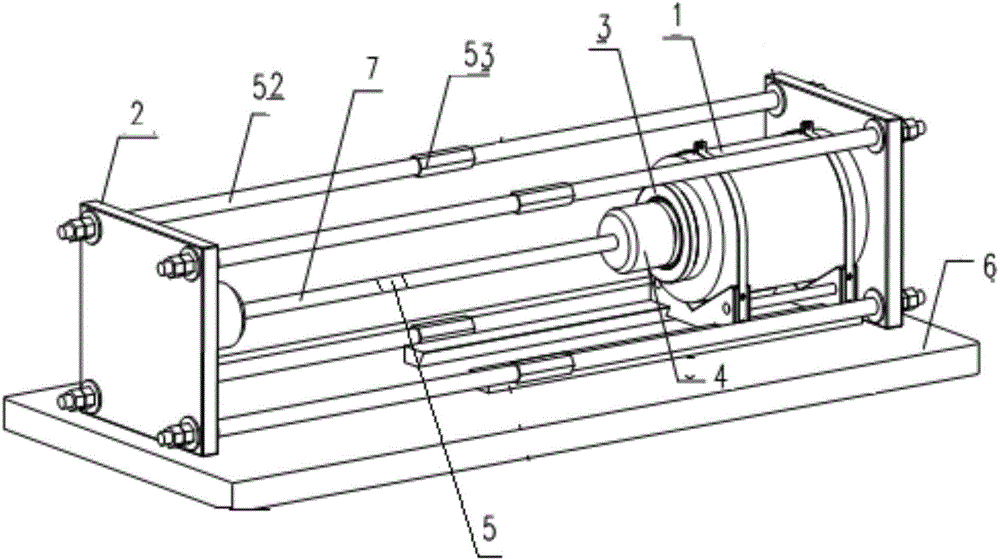

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , figure 2 , image 3 As shown, the strain gauge calibrating device of the present invention includes a sliding guide rail 6 and a strain gauge 7, and a jack assembly 1, a baffle plate 2 and a forced centering plate 3 are arranged on the slide guide rail 6, and the strain gauge 7 passes through the The jack assembly 1 , the baffle plate 2 and the forced centering plate 3 are clamped, and the strain gauge 7 is externally connected with a calibration detection device 5 .

[0021] Compared with the traditional structure, the structure of the present invention is more optimized and simplified. In actual use, the strain gauge 7 only needs to be clamped through the jack assembly 1, the baffle plate 2 and the forced centering plate 3 in sequence, and then the corresponding tension or pressure is applied through the jack assembly 1, and then the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com