Hypersonic wind tunnel airflow stabilizing device

A technology with stable airflow and hypersonic speed, which is applied in the field of aerodynamics, can solve the problems of uneven heating of the wall surface of the casing, reducing the compressive strength of the casing, and limiting the heating temperature of the stable section, so as to reduce the risk of wind tunnel operation, Effects of shortened start-up time and low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings.

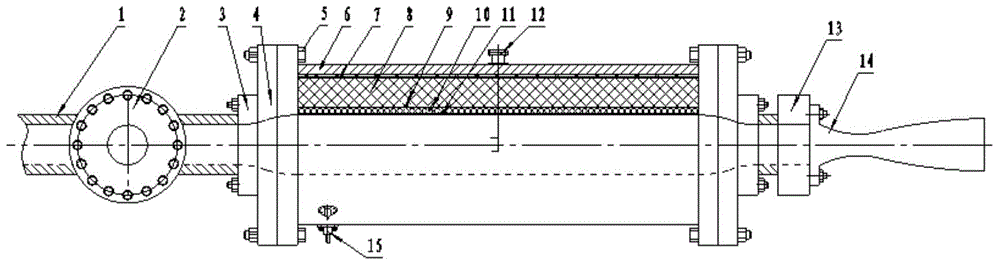

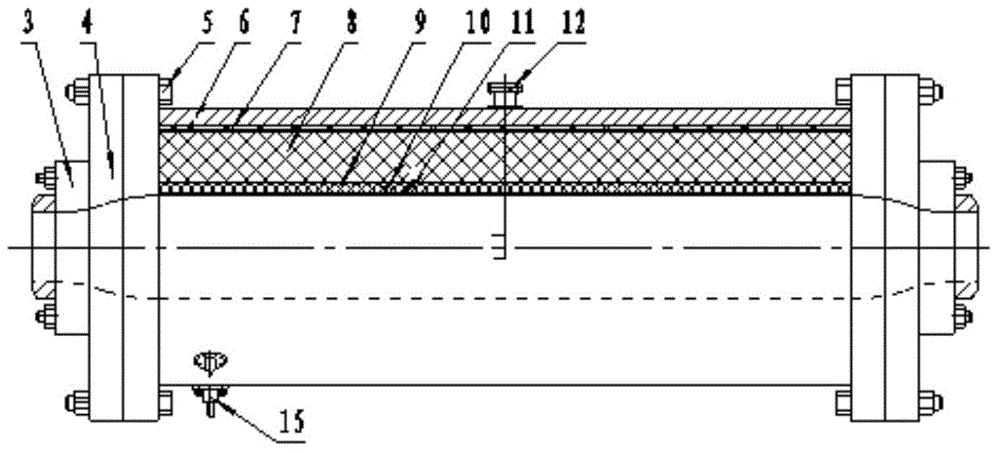

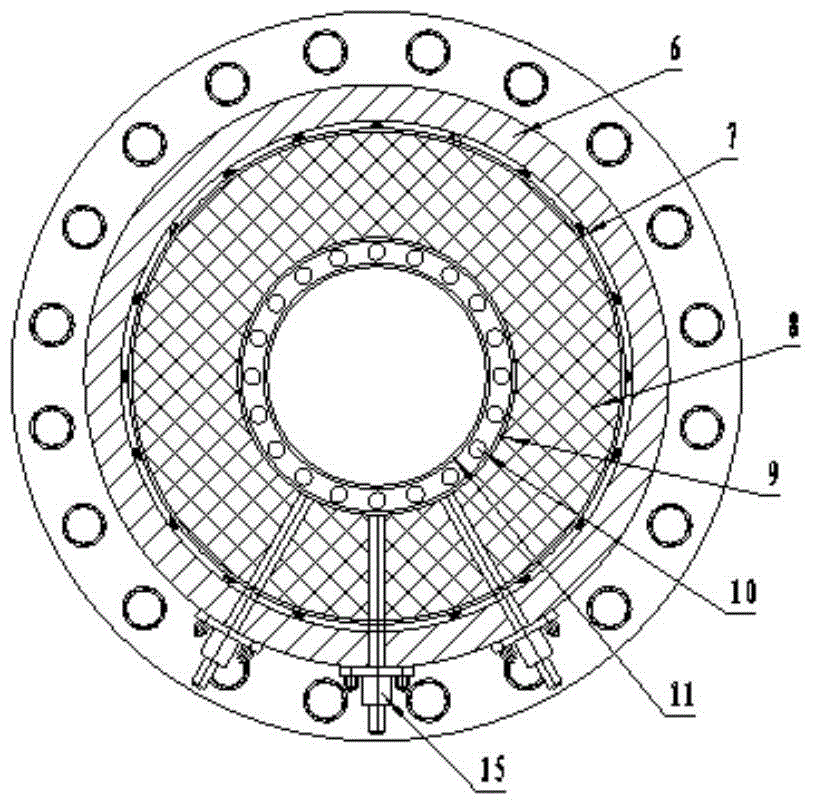

[0028] Such as figure 1 As shown in the system diagram of the airflow stabilization device, there are high-temperature and high-pressure pipelines 1 and high-temperature, high-pressure quick valve 2 in the front of the wind tunnel stabilization section, which are the air source input parts of the stabilization section, and the high-temperature and high-pressure airflow from the heater is passed through the control and input stable segment. The airflow decelerates, diffuses, and stabilizes in the stable section, and then passes through the contraction section to reach the outlet. The outlet of the stable section is connected to the locking mechanism 13, and is connected to the nozzle 14 through a hydraulic mechanism or a bolt fastener. There is a bent frame mounting seat 12 in the middle section of the shell cylinder 6, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com