Method and device for measuring friction factor of plastic micro forming

A technology of friction factor and measurement method, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of measurement errors of small-sized samples, and achieve the effect of high precision and simple experimental devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

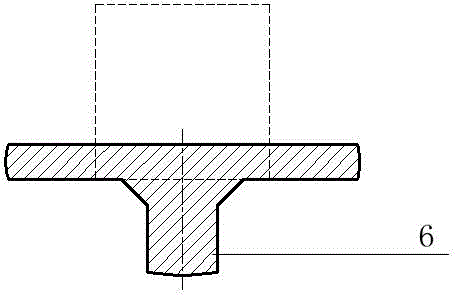

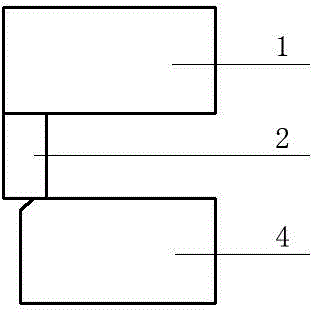

[0026] Such as figure 1 As shown, the measuring device used in the method for measuring the friction factor of plastic microforming in this embodiment is composed of an indenter 1, a sample 2, a positioning ring 3, a mold 4, a fixing ring 5, etc., and their combination sequence is as follows: And the indenter 1, the sample 2, the positioning ring 3, the mold 4 and the fixing ring 5 are arranged in sequence. The pressure head 1 can move up and down.

[0027] Both the mold 4 and the positioning ring 3 adopt a split design, the mold 4 is composed of two split molds, and the positioning ring 3 is composed of two split positioning rings. The split mold 4 is designed to facilitate the removal of parts, and the divided positioning ring 3 is designed to facilitate the removal of the positioning ring 3 after the indenter compresses the sample.

[0028] The sample 2 is cylindrical, and the positioning ring 3 after the two petals are bonded is in the shape of an inverted cup. The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com