drive unit for vehicle

A driving device and vehicle technology, applied in the direction of electrical devices, power devices, electric power devices, etc., can solve the problems of increased assembly man-hours, increased manufacturing costs, and increased number of parts, so as to reduce the number of parts and improve freedom. The effect of simplification and simplification of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

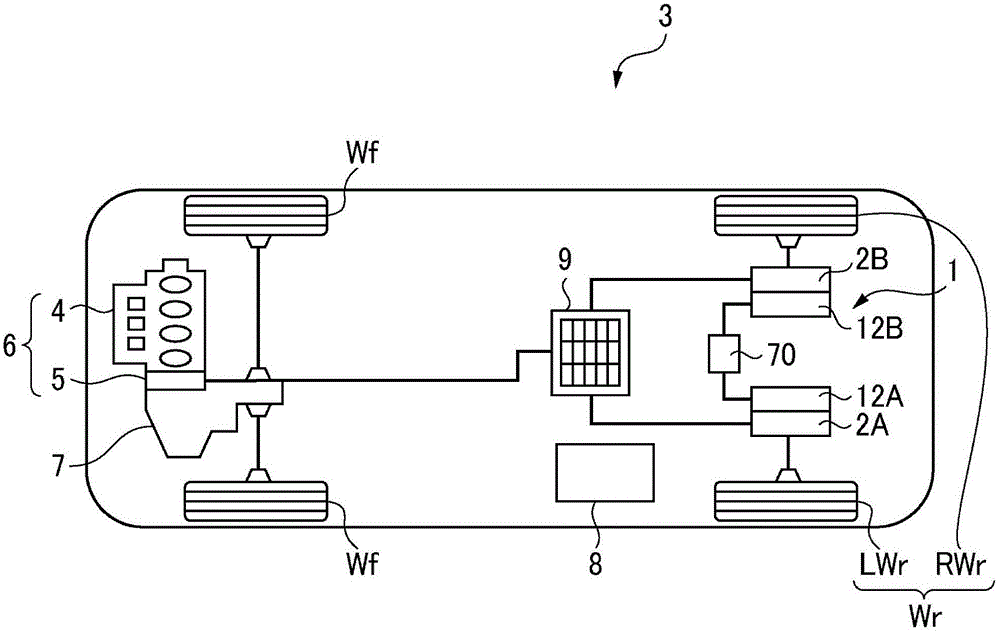

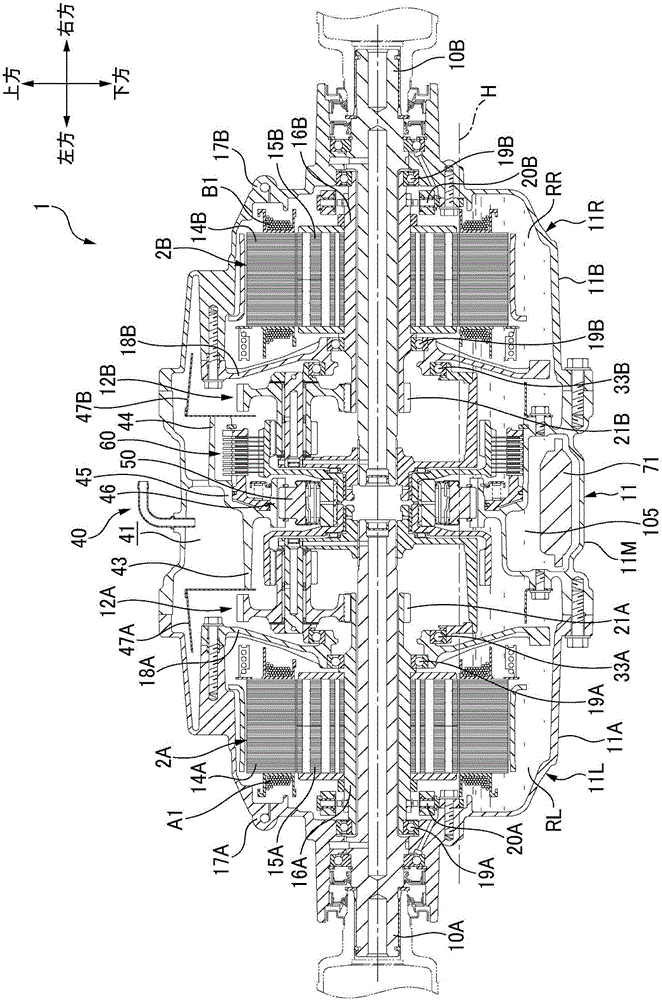

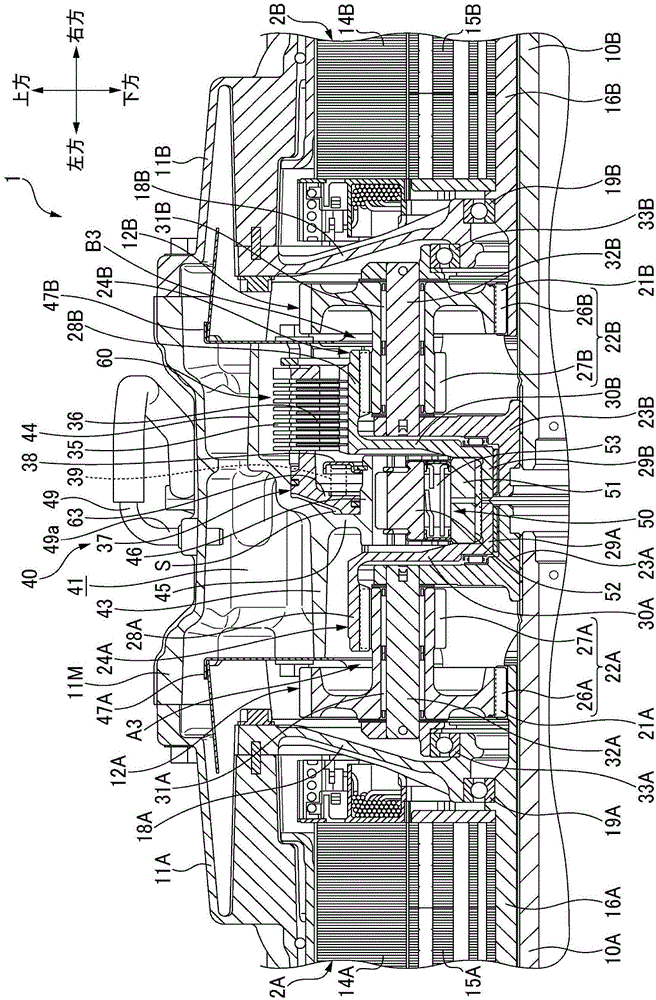

[0077] The driving device for a vehicle of the present invention is a device in which an electric motor is used as a driving source for wheel driving, and is used, for example, figure 1 A vehicle with a drive system as shown. In the following description, a case where the vehicle drive device is used for driving the rear wheels will be described as an example, but it may also be used for driving the front wheels.

[0078] figure 1 The illustrated vehicle 3 is a hybrid vehicle having a driving device 6 (hereinafter referred to as a front-wheel drive device) in which an internal combustion engine 4 and an electric motor 5 are connected in series at the front of the vehicle. The transmission device 7 transmits power to the front wheels Wf, and on the other hand, the drive device 1 (hereinafter, referred to as a rear wheel drive device) provided at the rear of the vehicle differently from the front wheel drive device 6 transmits power to the rear wheels Wr (RWr , LWr) transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com