Power conversion device

A technology for power conversion devices and mounting components, which is applied to output power conversion devices, circuit devices, printed circuit grounding devices, etc. Substrate cost, heat generation suppression, and effects of improved noise resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

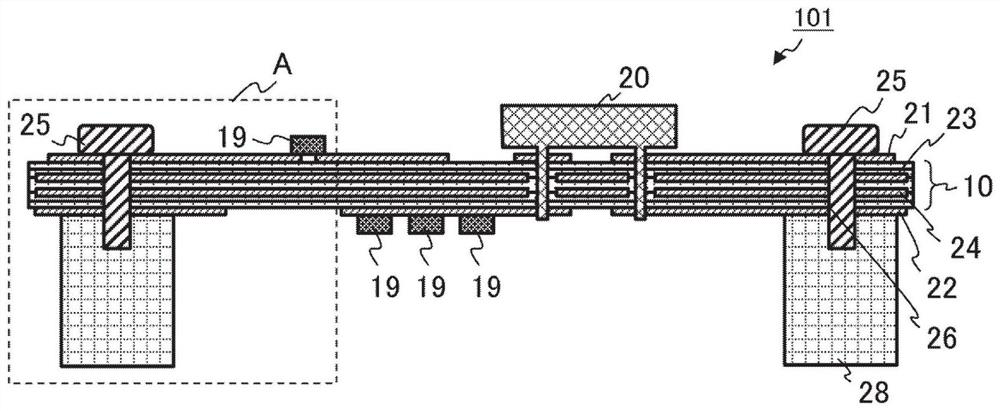

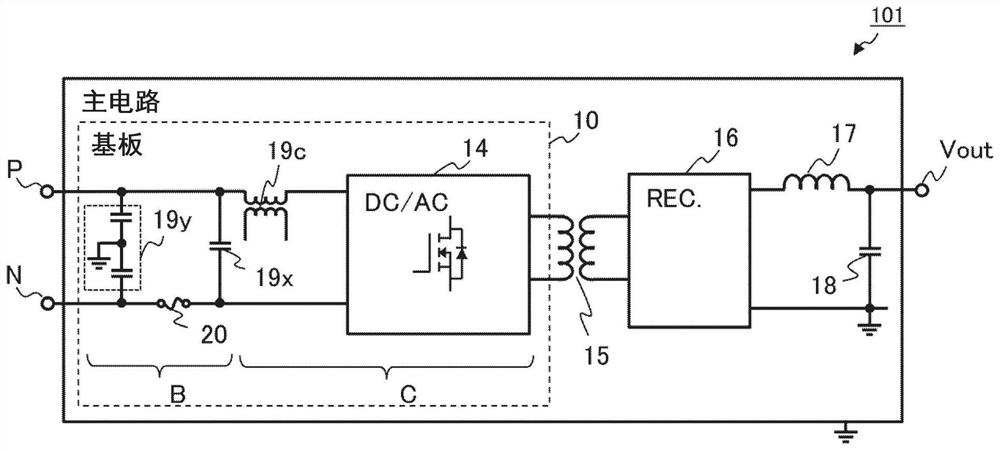

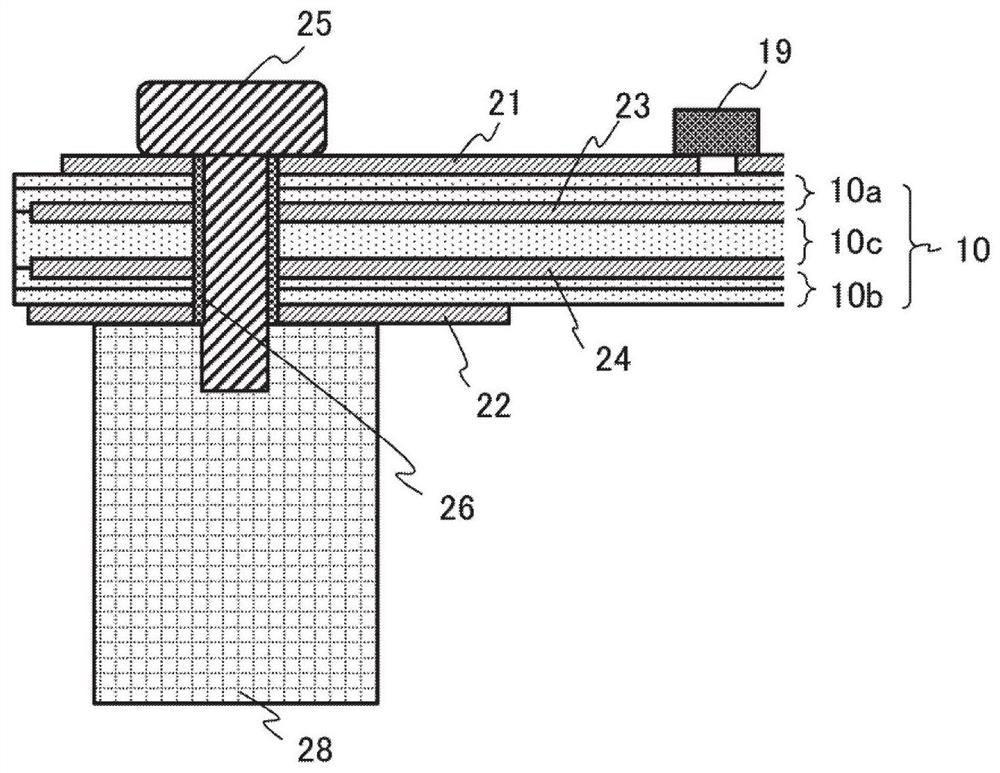

[0026] figure 1 It is a sectional view showing the configuration of the main circuit of the power conversion device according to the first embodiment. figure 2 It is a circuit diagram showing the configuration of the main circuit of the power conversion device. image 3 yes figure 1 A partial enlargement of area A of .

[0027] Such as figure 1 As shown, the main circuit 101 of the power conversion device according to Embodiment 1 is configured to include: a substrate 10; a first wiring layer 21 and a second wiring layer 22 provided on both sides of the substrate 10; The first GND layer 23 and the second GND layer 24 which are arranged on the inner layer part of the substrate 10 under the layer 22 respectively; part 19; a lead insertion part 20 arranged on the surface of the substrate 10 and connected to the first wiring layer 21 and the second wiring layer 22; and a cooler (or case) 28 through which The mounting screw 25 is attached to a through hole 26 as a first throu...

Embodiment approach 2

[0048] In Embodiment 1, a case where wiring layers and GND layers are a four-layer substrate is shown, but in Embodiment 2, a case where wiring layers and GND layers are a six-layer substrate will be described.

[0049] Figure 5 It is a sectional view showing the configuration of the main circuit of the power conversion device according to the second embodiment. Figure 6 yes Figure 5 A partial enlargement of region D of . Such as Figure 5 and Figure 6 As shown in FIG. figure 1 21, Figure 5 , Figure 6 21a) between the first GND layer 23 and the second wiring layer ( figure 1 22, Figure 5 , Figure 6 22a) and the second GND layer 24 are respectively provided with a third wiring layer ( Figure 5 , Figure 6 21b) with the fourth wiring layer ( Figure 5 , Figure 6 22b). Other configurations of the main circuit 102 of the power conversion device according to the second embodiment are the same as those of the main circuit 101 of the power conversion device ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com