Probe and method for measuring humidity of wet steam by rigid microwave coaxial line

A technology of humidity measurement and coaxial line, applied in the field of wet steam humidity measurement probe, can solve the problems of inability to accurately measure wet steam humidity, heat dissipation and thermal inertia, and difficulty in accurate measurement of heating amount, etc. Conducive to the effect of accurate measurement, fast heating and reducing thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

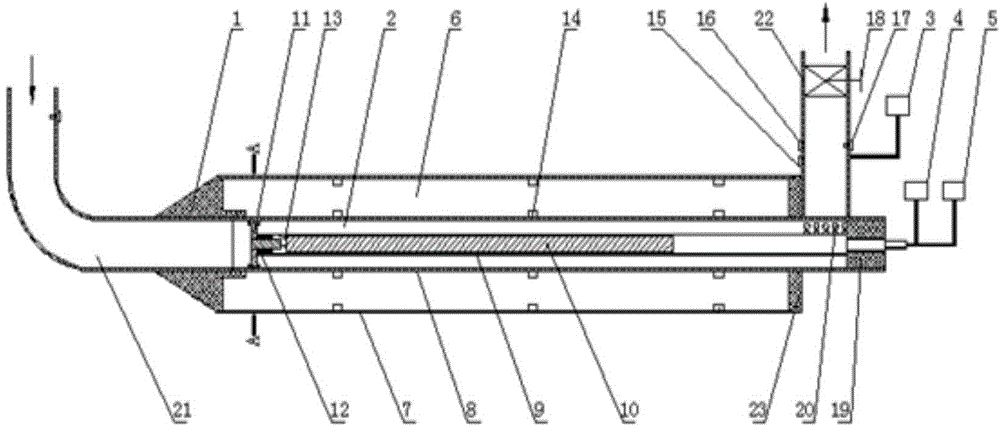

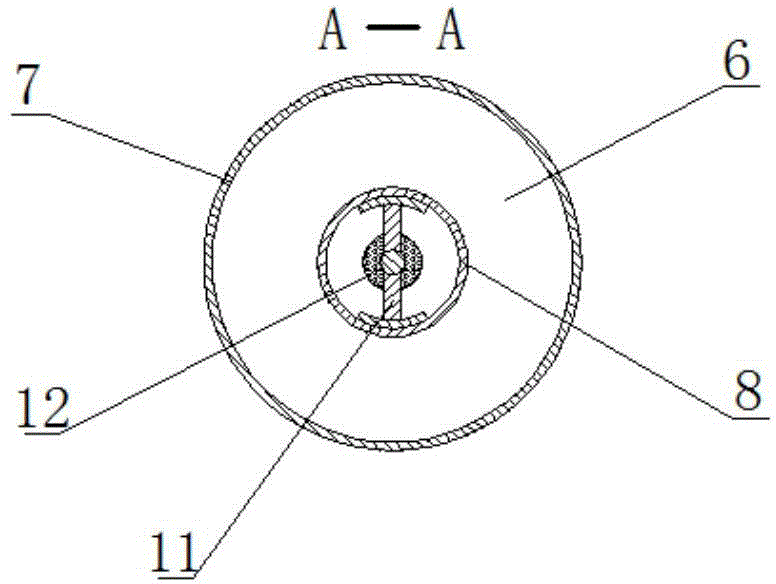

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] refer to figure 1 and figure 2, the moisture vapor humidity measuring probe utilizing microwave hard coaxial cable according to the present invention comprises a hard coaxial cable outer conductor 8, a sampling head 21, an end connector 1, an outer sleeve 7, a rear end cover 23, and a draft tube 22. Regulating valve 18, vacuuming equipment, T-shaped positioning bracket 11, ceramic sleeve 12, hard coaxial inner conductor 9, microwave source 5, microwave power meter 4, porous corundum rod 10, hard coaxial terminal resistance 13 and data acquisition system 3; one end of the hard coaxial outer conductor 8 and one end of the sampling head 21 are all sleeved in the end connector 1, and the sampling head 21 is connected with the hard coaxial outer conductor 8, and the outer casing 7 The two ends of the two ends are respectively socketed on the end connector 1 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com