Single-mode fiber with ultra-low attenuation and large effective area

An effective-area, single-mode fiber technology, applied in multi-layer core/clad fibers, clad fibers, light guides, etc., can solve the problems of high core viscosity, reduced fiber attenuation performance, high cost, and increase the effective area. , bending loss improvement, the effect of reducing the attenuation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the embodiments.

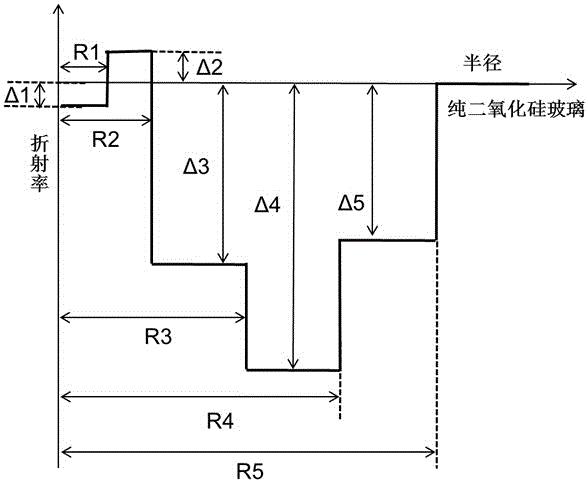

[0026] It includes a core layer and a cladding layer, the core layer includes a sunken core layer and an outer core layer from the center to the outside, and the cladding layer includes an inner cladding layer, a sunken inner cladding layer, an auxiliary outer cladding layer and an outer cladding layer from the inside to the outside, wherein , the radius of the sunken core layer is R 1 , the relative refractive index difference is , the radius of the outer core layer is R 2 , the relative refractive index difference is , the inner cladding radius is R 3 , the relative refractive index difference is , the radius of the sunk inner cladding is R 4 , the relative refractive index difference is , the radius of the auxiliary inner cladding is R 5 , the relative refractive index difference is , the outer cladding is pure silica glass layer, the outer cladding radius R 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com