Display substrate, display panel, manufacturing method thereof, and display device

A manufacturing method and display substrate technology, which can be applied in the fields of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., and can solve problems such as the influence of display substrates and display panel manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

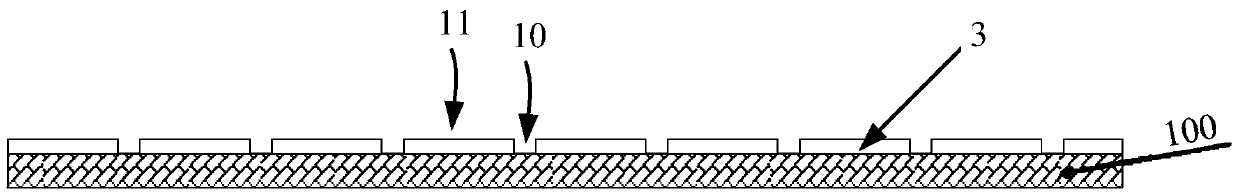

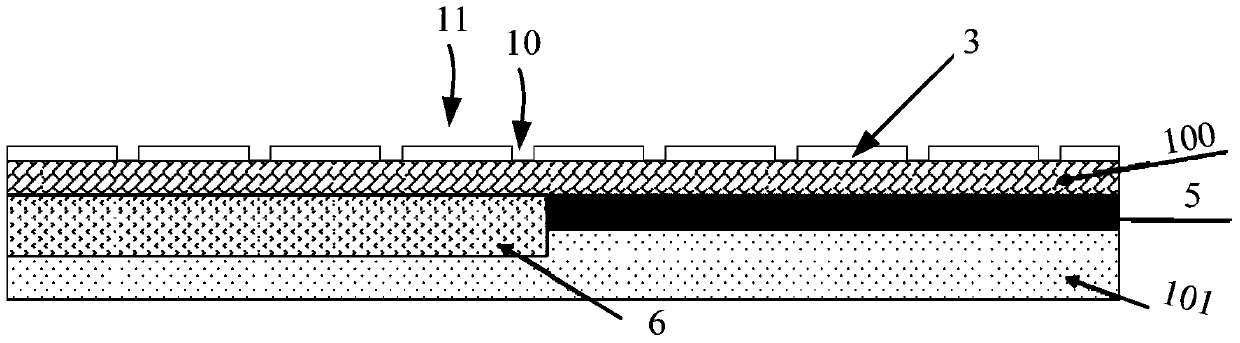

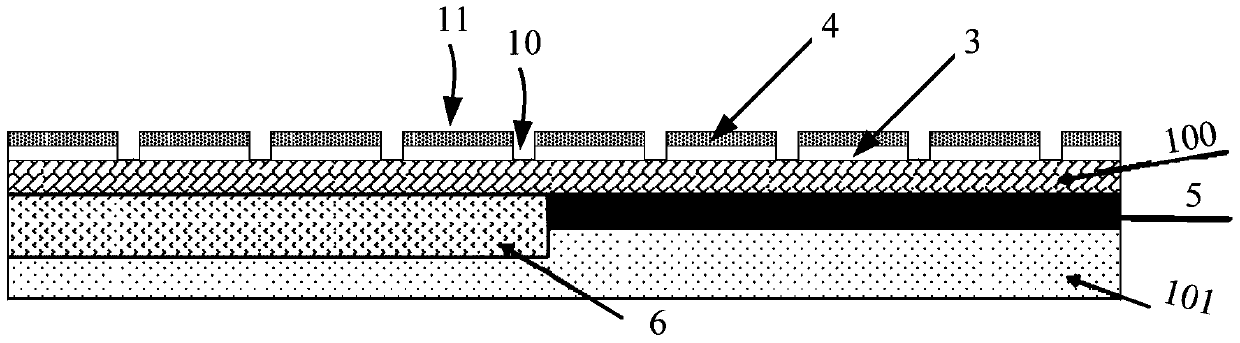

[0056] In the prior art, when the display substrate and the grating are integrated, since the light-shielding stripes of the grating are made of black photoresist, in order to meet a sufficiently low light transmittance, the thickness is relatively thick, often several microns, resulting in subsequent formation The problem that the substrate substrate is not firmly adsorbed when displaying the film layer. However, if the display film layer is formed first, the manufacturing process of the grating will have an impact on the display film layer.

[0057]In view of the above-mentioned technical problems, the present invention provides a method for manufacturing a display substrate. The method first forms a grating stripe pattern on one surface of the base substrate through a stable interposer, wherein the interposer and the base substrate One of them has the property of adsorbing a certain opaque material, and the other does not have the property of adsorbing said opaque material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com