Method and device for achieving return of electric lifting table when obstruction is encountered through current dual-filter mode

A lifting table and double-filtering technology, which is applied in the field of current double-filtering to realize the return of electric lifting tables in case of resistance and devices, can solve the complex manufacturing process of sensors and strain gauges, the influence of the sensitivity of system resistance and return, and the problems of sensors and strain gauges. Difficulty in installation and other issues, to achieve the effect of simple structure, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for realizing the retreat of an electric lifting table in case of resistance in a current double filtering method. The electric lifting table is lifted and lowered by the motor 1. The method includes the following steps:

[0044] Step a, obtaining the current signal flowing through the motor 1 and converting it into a voltage signal;

[0045] Step b, filtering the voltage signal;

[0046] Step c, collecting the voltage value of the voltage signal after filtering and processing, and then obtaining a comparison value;

[0047] Step d. Comparing the comparison value with the set value, making a decision to control the forward and reverse rotation of the motor 1 .

[0048] The calculation processing method in step c includes the following steps:

[0049] Step 1, collecting the voltage value of the filtered voltage signal N times to obtain N voltage values, and obtaining the sum of the N voltage values, where N>2;

[0050] Step 2. Repeat step 1 X times to obtain ...

Embodiment 2

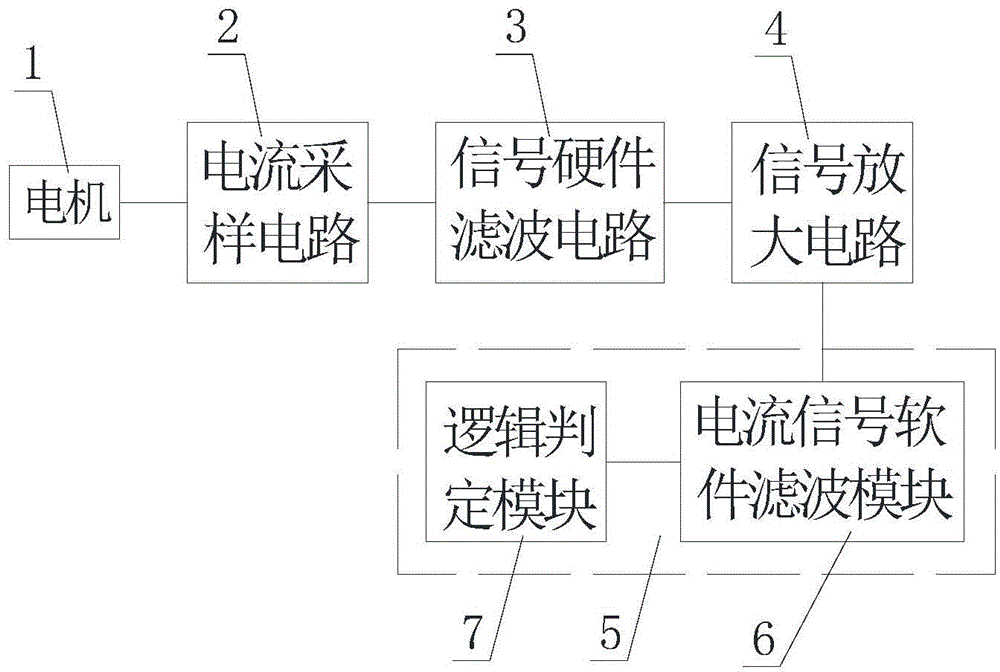

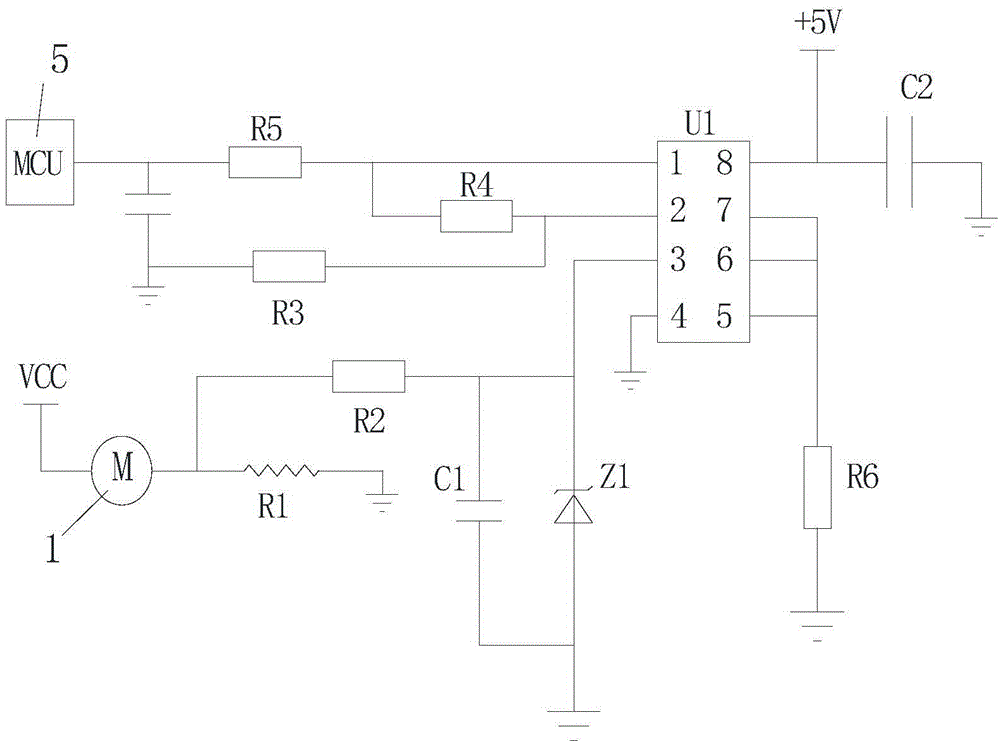

[0056] Such as Figures 1 to 2As shown, a current dual filtering method realizes the device for the electric lifting table to fall back when encountering resistance. The electric lifting table is driven by the motor 1. The device includes a current sampling circuit 2, a signal hardware filter circuit 3, a signal amplification circuit 4 and a single-chip microcomputer 5. The motor 1 is electrically connected to the single-chip microcomputer and is controlled to work. The motor 1, the current sampling circuit 2, the signal hardware filter circuit 3, the signal amplification circuit 4, and the single-chip microcomputer are electrically connected in turn. The single-chip microcomputer has a current signal software filtering module 6 and a logic judgment module 7. The current signal software filter module 6 performs arithmetic processing on the electrical signal input by the signal amplifier circuit 4 and then sends it to the logic judgment module 7 for judgment, thereby realizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com