Gas cylinder replacing system and method

A gas cylinder and gas type technology, which is applied in the direction of collaborative operation of devices, instruments, calculations, etc., and can solve problems such as gas cylinder replacement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

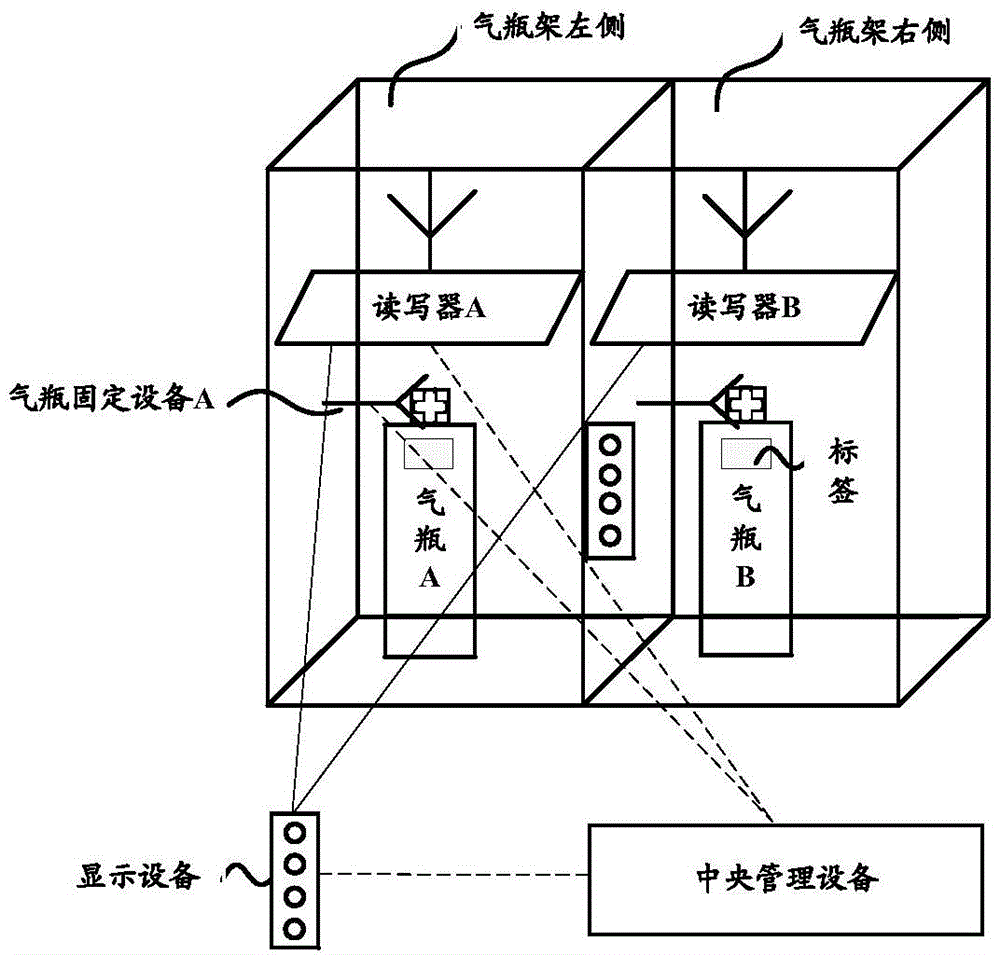

[0042] Embodiment 1 provides a gas cylinder replacement system, such as figure 1 As shown, it is a schematic structural diagram of the gas cylinder replacement system, which specifically includes: two readers, two gas cylinder fixing devices, display devices and central management devices. in,

[0043] The two readers are installed on the gas cylinder rack, and by adjusting the relevant parameters of the reader, the reader installed on the left side of the gas cylinder rack reads the The label on the gas cylinder, the reader installed on the right side of the gas cylinder rack reads the label on the gas cylinder placed on the right side of the gas cylinder rack, without misreading the gas cylinder on the opposite side of the gas cylinder and other gas cylinders. Label information on cylinders placed in bottle racks.

[0044] Wherein, the label information of the label on the gas cylinder is adapted to the gas type filled in the gas cylinder, and the label information of the ...

Embodiment 2

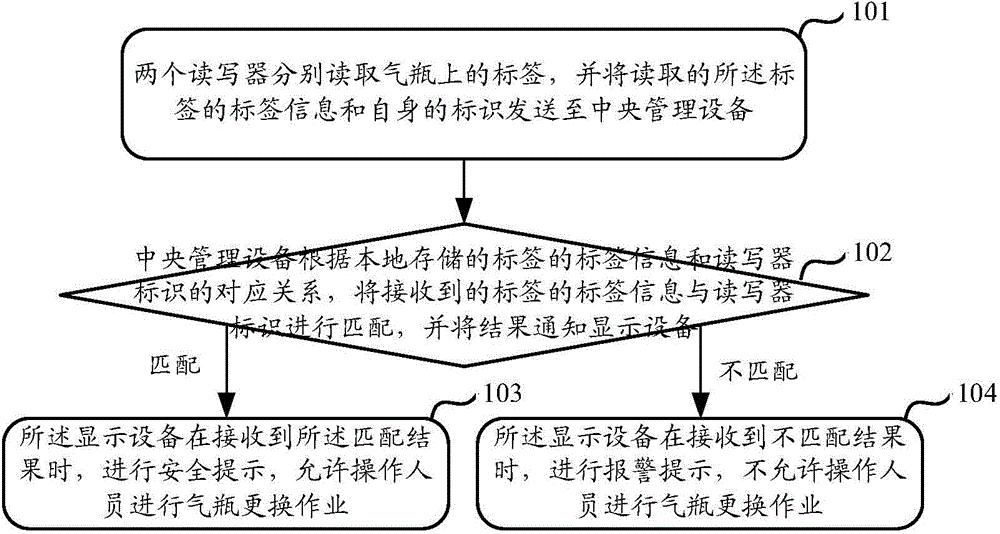

[0061] In Embodiment 2 of the present invention, a method for replacing a gas cylinder is provided, such as figure 2 As shown, the flow chart of the method steps for gas cylinder replacement provided by Embodiment 2 of the present invention specifically includes the following steps:

[0062] Step 101: two readers respectively read the tags on the gas cylinders, and send the read tag information and their own identification to the central management device.

[0063] Wherein, the two readers are installed on the gas cylinder rack, the reader installed on the left side of the gas cylinder rack reads the label on the gas cylinder placed on the left side of the gas cylinder rack, and is installed on the right side of the gas cylinder rack The reader reads the tags on the cylinders placed on the right side of the cylinder rack.

[0064] Step 102: The central management device matches the received label information of the tag with the reader-writer identifier according to the corre...

Embodiment 3

[0069] The following describes the gas cylinder replacement process in detail in combination with specific application scenarios.

[0070] Assume that the type of gas required to be provided on the left side of the gas cylinder rack is A, the type of gas required to be provided on the right side of the gas cylinder rack is B, the type of gas filled in gas cylinder A is A, and the type of gas filled in gas cylinder B is B; and the reader A is installed on the left side of the gas cylinder rack, and the reader B is installed on the right side of the gas cylinder rack, wherein, the reader A can only read the gas located on the left side of the gas cylinder rack. For the label information on the bottle, the reader B can only read the label information on the gas cylinder located on the right side of the gas cylinder rack.

[0071] Scenario 1: The gas cylinder is replaced correctly

[0072] Specifically, when changing the gas cylinder on the left side of the gas cylinder rack, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com