Off-circuit tap-changer for transformation after force discharging of moving contact

A technology of tap changer and moving contact, applied in the direction of electric switch, contact electrical connection, contact drive mechanism, etc., can solve the problems of inability to reverse rotation when changing gears, large torque, shortening insulation distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

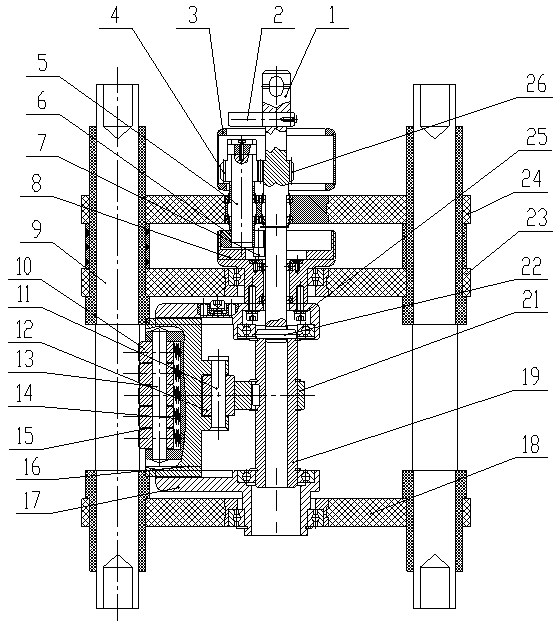

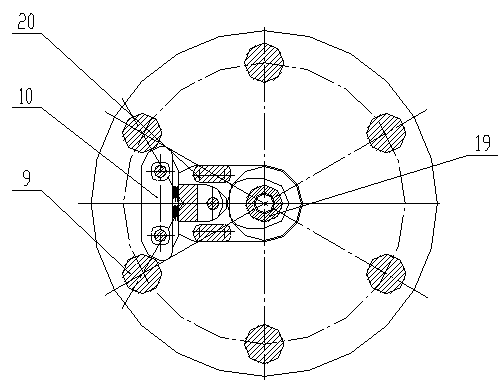

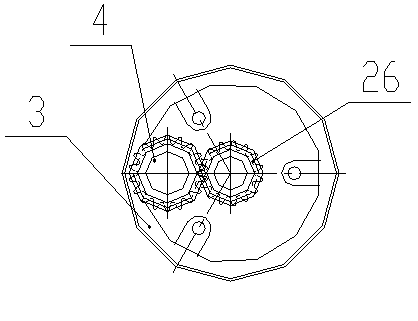

[0027] The purpose of the present invention is to solve the performance requirements of reliable and stable contact of off-excitation tap changer, accurate contact gear position and small shift torque, and can remove contact contact foreign objects (for example: non-conductive carbon-like objects, Non-conductive other substances in the transformer oil, etc.), the following will be further explained in conjunction with the accompanying drawings.

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown in the figure, a non-excitation tap changer is converted after the moving contact is unloaded, including the main shaft 1, the gear indicator rod 2, the shield cover 3, the gear system, the sheave system, the contact bracket, the moving contact system, the static contact Head system, cam system.

[0029] Main shaft 1 is used to provide rotational torque to the switch gear system and the cam system.

[0030] The gear indicating rod 2 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com