Panel feeding and detecting device

A technology for inspection devices and panels, applied in the direction of electrical components, circuits, semiconductor/solid-state device testing/measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] The invention is a panel feeding inspection device, which automates the panel picking and placing, improves the efficiency and accuracy of panel inspection, and at the same time reduces the risk of fragments caused by personnel during picking and placing operations.

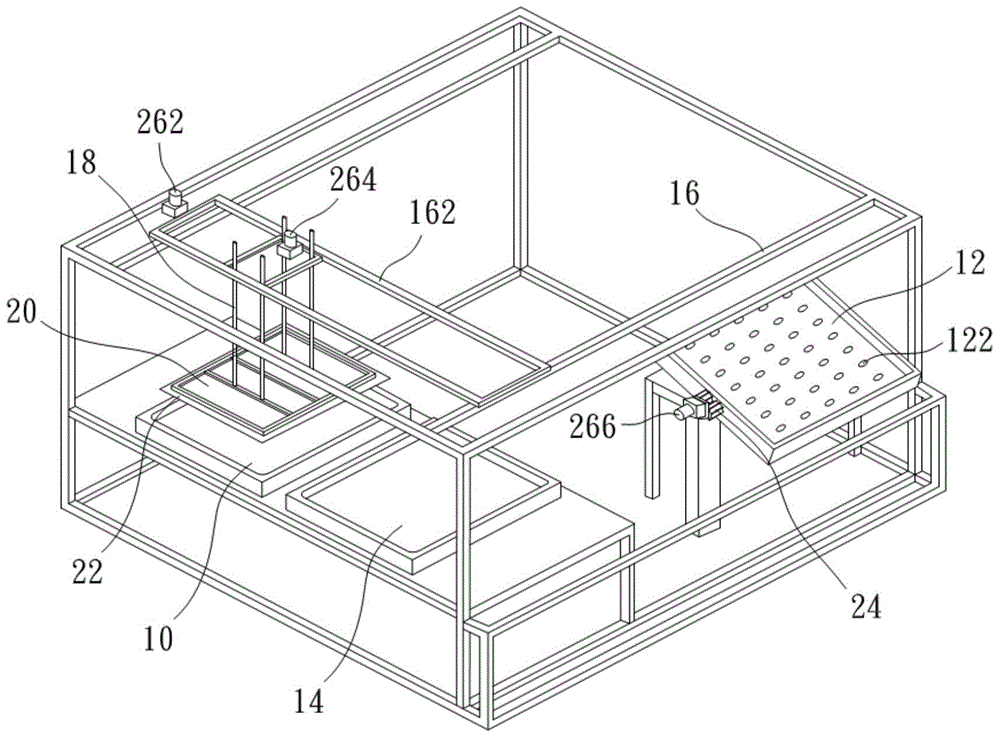

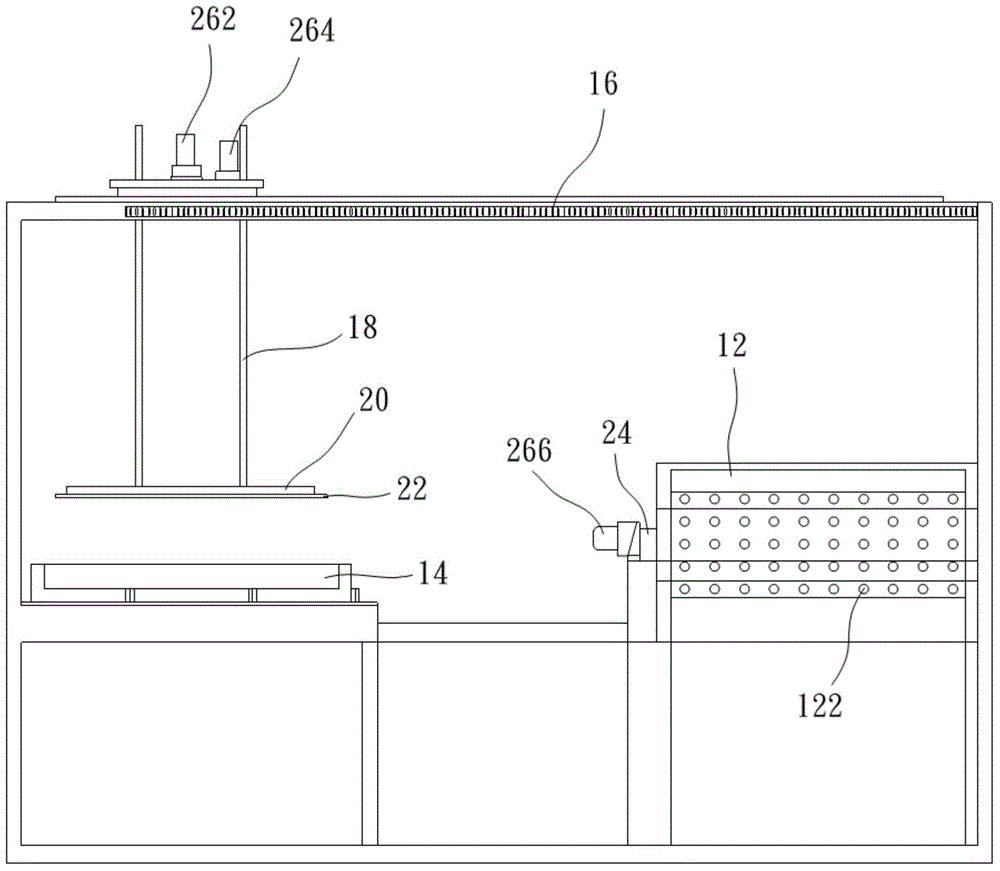

[0029] Please refer to figure 2 , which is a perspective view of the panel feeding inspection device of the present invention. The present invention includes a feeding place 10, a receiving place 14 and a light box 12, wherein the feeding place 10 is used to place the panel 22 to be inspected, and the light box 12 provides At least one light source 122, this light source 122 can be a light emitting diode (LED), when the panel 22 is placed on the light box 12, the light source 122 emits light and shines on the panel 22, and the reflected light of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com