Cable connector clamping device

A technology of cable joints and clamping devices, which is applied in the direction of cable joints, connections, line/collector components, etc., can solve problems such as short circuits in wiring systems, insufficient winding, safety accidents, etc., to speed up efficiency and avoid inefficiency , the effect of protecting against damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

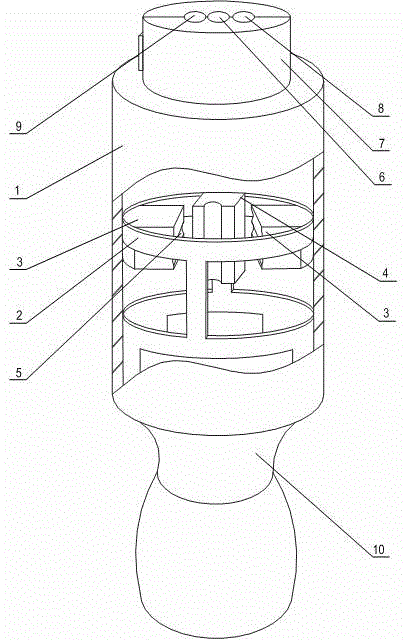

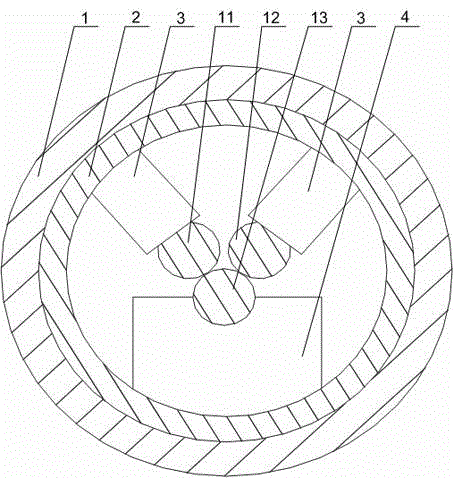

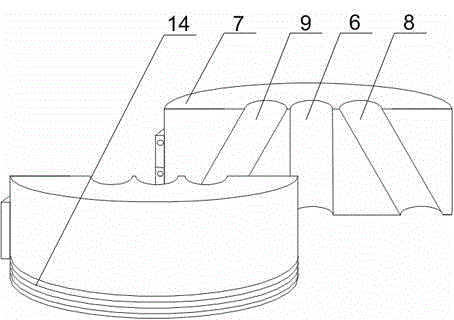

[0021] like Figure 1 to Figure 3As shown, this embodiment includes a cylinder body 1 with open upper and lower ends and a screw thread on its inner wall. Two joints 7 hinged to each other are movably arranged on the upper open end of the cylinder body 1, and one joint joint 7 There are three semi-circular grooves on the upper part of the connector. When the two lugs 7 are closed, two of the six semi-circular grooves respectively form the through hole A8, the through hole B9 and the through hole C6, and the axis of the through hole A8 is vertically downward. , the axis of the through hole B9 is inclined downward along the vertical direction, and the axes of the through hole C6 and the through hole B9 are arranged symmetrically along the axis of the through hole A8. The rotating bracket 2, the rotating bracket 2 runs through the lower end of the cylinder body 1, and the end of the rotating bracket 2 is connected with a handle 10, two winding blocks 3 and a limiting block 4 are ...

Embodiment 2

[0023] like figure 1 and image 3 As shown, in this embodiment, on the basis of Embodiment 1, an external thread 12 is provided on the outer wall of the lower end of the terminal head 7 , and the two terminal heads 7 are threadedly connected to the upper open end of the cylinder body 1 . As preferably, the threaded connection between the terminal head 7 and the cylinder body 1 is convenient for the quick separation of the wire head and the device after the two wire cores are entangled with each other, and the speed of connection is accelerated. Meanwhile, the threaded connection can also make the wire cores in the mutual Prevent the cable from rotating when winding, and avoid unstable connection of the entire wiring system.

[0024] The rotating bracket 2 includes an upper ring and a lower ring that are connected to each other and arranged at intervals. The upper ring and the lower ring are respectively screwed to the inner wall of the cylinder body 1. The winding block 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com