Lubricating composition

A technology of lubricating composition and comb polymer, which is applied in the direction of lubricating composition, petroleum industry, etc., and can solve the problems of long-term or continuous fuel economy of undisclosed comb polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Poly-alpha olefin base oils (PAOs) and their preparation are well known in the art. Preferred poly-alpha olefin base oils that may be used in the lubricating compositions of the present invention may be derived from linear C 2 -C 32 , preferably C 6 -C 16 , alpha olefins. Particularly preferred starting materials for the poly-alphaolefins are 1-octene, 1-decene, 1-dodecene and 1-tetradecene.

[0025] In view of the high production costs of PAOs, the use of base oils of Fischer-Tropsch origin is strongly preferred over PAO base oils. Thus, preferably, the base oil contains more than 50 wt.%, preferably more than 60 wt.%, more preferably more than 70 wt.%, even more preferably more than 80 wt.%. Most preferably greater than 90 wt.% Fischer-Tropsch derived base oil. In a particularly preferred embodiment, not more than 5 wt.%, preferably not more than 2 wt.%, of the base oil is not a base oil of Fischer-Tropsch origin. Even more preferably 100% by weight of the base...

Embodiment

[0103] lubricating oil composition

[0104] A wide variety of engine oils are formulated for use in crankcase engines.

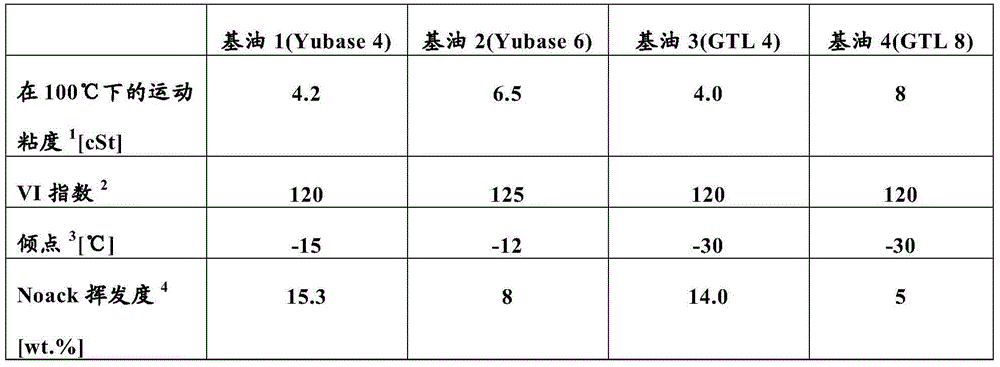

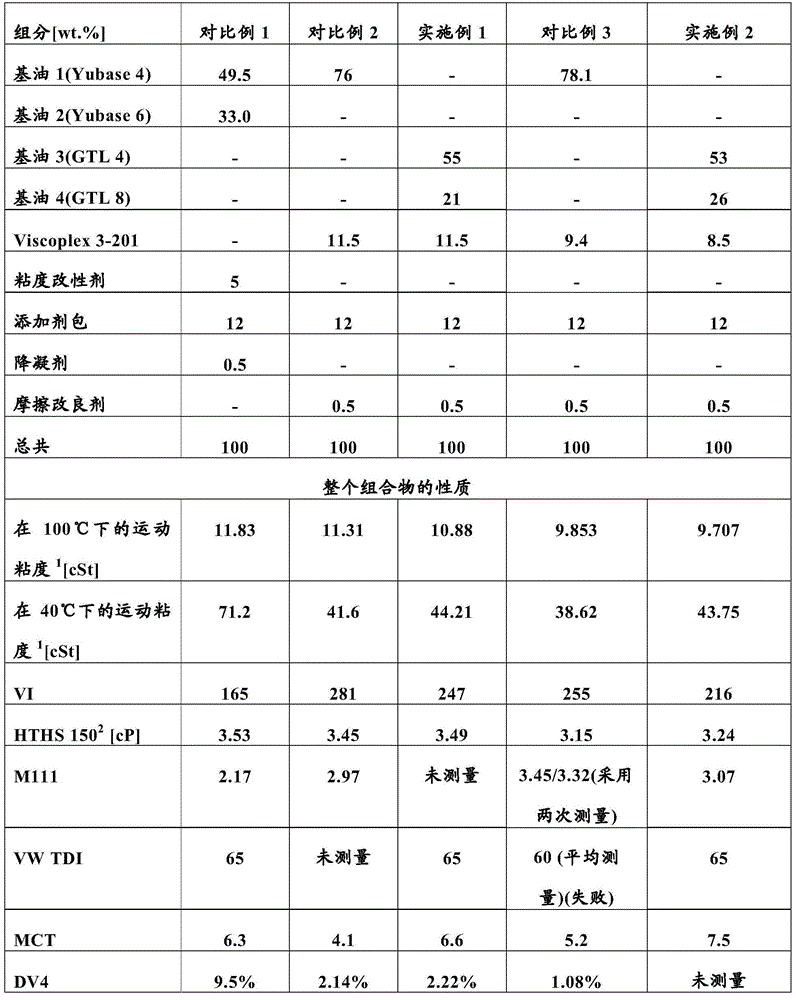

[0105] Table 1 shows the properties of the base oils used. Table 2 shows the composition and properties of the fully formulated engine oil formulations tested; the contents of the components are given in wt.%, based on the total weight of the fully formulated formulations.

[0106] "Base Oil 1" is a commercially available Group III base oil with a kinematic viscosity (ASTM D445) of 4.2 cSt (average) at 100°C. Base Oil 1 is commercially available from, for example, SK Energy (Ulsan, South Korea) (under the trade name "Yubase 4").

[0107] "Base Oil 2" is a commercially available Group III base oil with a kinematic viscosity (ASTM D445) of 6.5 cSt (average) at 100°C. Base Oil 2 is commercially available from, for example, SK Energy (Ulsan, South Korea) (under the trade name "Yubase 6").

[0108] "Base Oil 3" is a Fischer-Tropsch derived base oil ("GTL 4") ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com