A skid-mounted Claus sulfur tail gas treatment device

A tail gas treatment, skid-mounted technology, applied in the direction of sulfur preparation/purification, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of failing to meet environmental emission standards, large energy consumption for regeneration, and serious equipment corrosion. Achieve the effects of solving excessive sulfur content, improving recovery efficiency and purity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

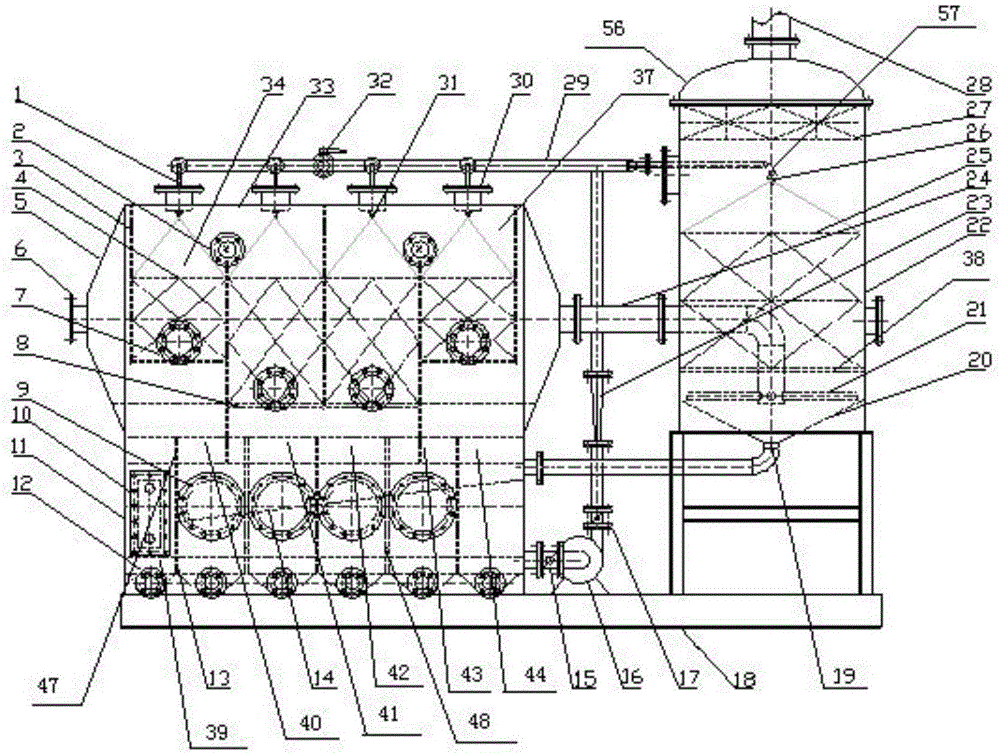

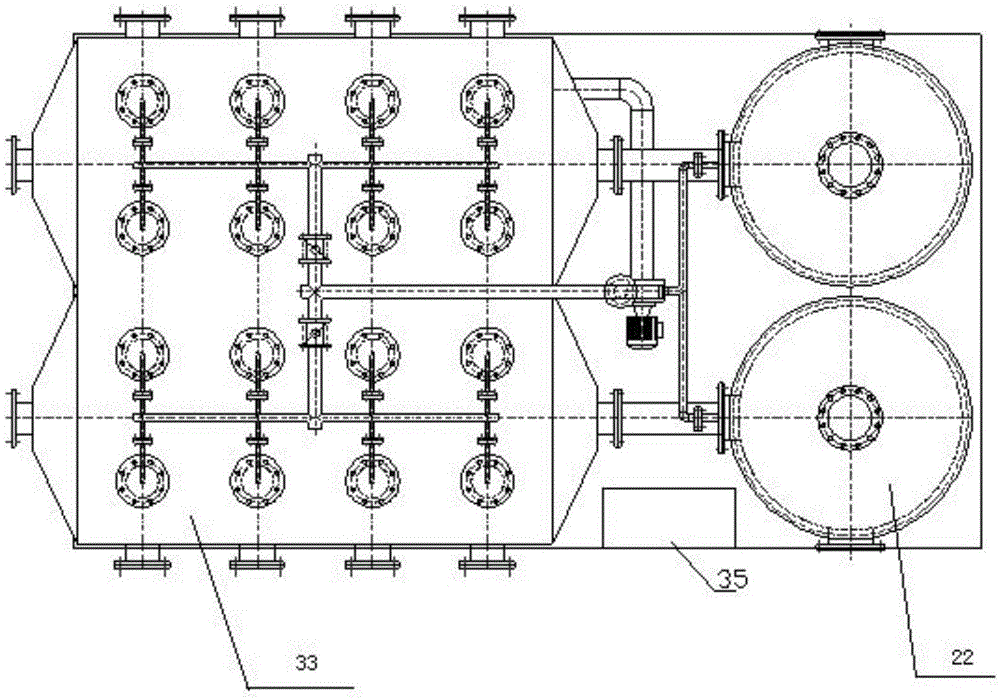

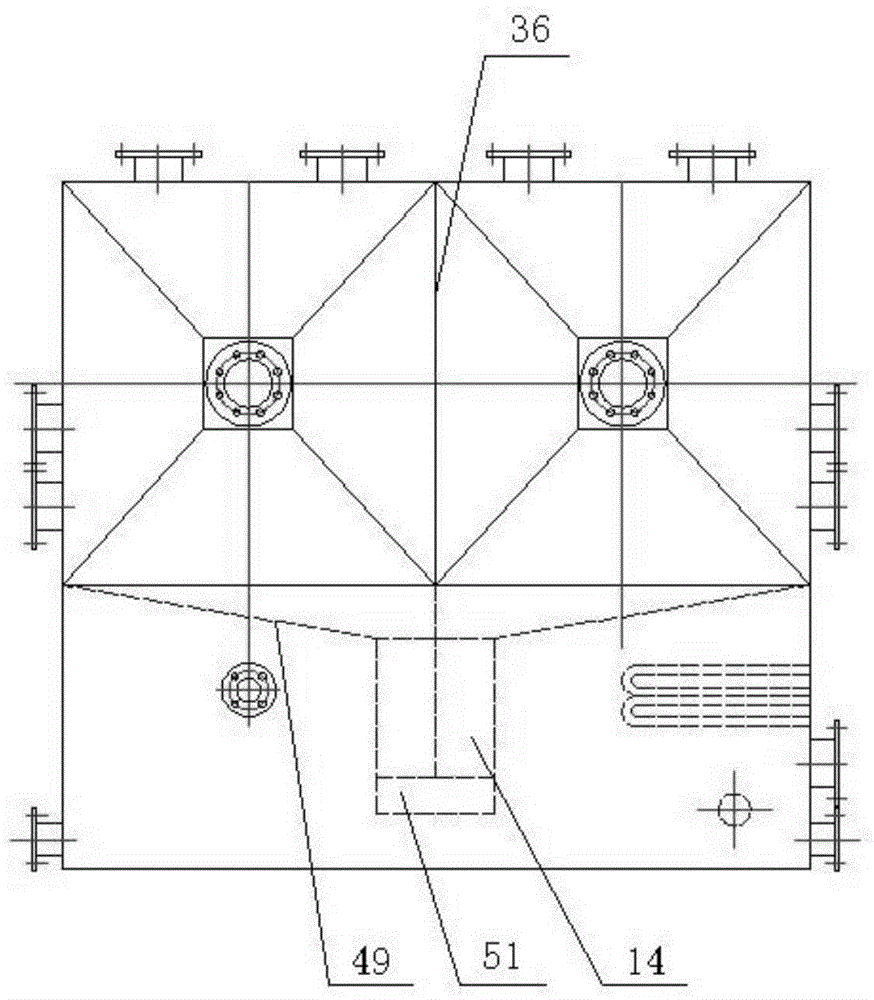

[0033] refer to Figure 1 to Figure 4 , a skid-mounted Claus sulfur tail gas treatment device, including two absorption towers 33, an electrolytic tank 11 and a secondary absorption tower 22.

[0034] The absorption tower 33 is rectangular and horizontal, and the ratio of length, width and height of the absorption tower 33 is 2:1:1. The electrolytic box 11 is welded at the bottom of the absorption tower 33 . Both ends of the absorption tower 33 are respectively provided with a first air inlet 6 and an air outlet 24 . Two absorption towers 33 are separated by central dividing plate 36, and the top of central dividing plate 36 is rectangle, and the bottom of central dividing plate 36 is right-angled trapezoid, and rectangular length is identical with absorption tower 33 lengths, and rectangular width is 1.8 of absorption tower 33 heights. times, the upper bottom of the right-angled trapezoid is the same as the length of the rectangle, and the length of the lower bottom of the ...

Embodiment 2

[0048] A skid-mounted Claus sulfur-containing tail gas treatment device includes two absorption towers 33 , an electrolysis box 11 and a secondary absorption tower 22 .

[0049]The absorption tower 33 is rectangular and horizontal, and the ratio of length, width and height of the absorption tower 33 is 2.8:1:1. The electrolytic box 11 is welded at the bottom of the absorption tower 33 . Both ends of the absorption tower 33 are respectively provided with a first air inlet 6 and a first air outlet 24 . Two absorption towers 33 are separated by central dividing plate 36, and the top of central dividing plate 36 is rectangle, and the bottom of central dividing plate 36 is right-angled trapezoid, and rectangular length is identical with absorption tower 33 lengths, and rectangular width is 1.6 of absorption tower 33 heights. times, the upper bottom of the right-angled trapezoid is the same as the length of the rectangle, and the length of the lower bottom of the right-angled trape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com