Integrated crawler full-mobility crushing station

A fully mobile crushing station technology, applied in the field of machinery, can solve the problems of high construction cost, long construction period, and low work efficiency of crushing stations, and achieve the effects of simple structure, large production capacity, and short mobile auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

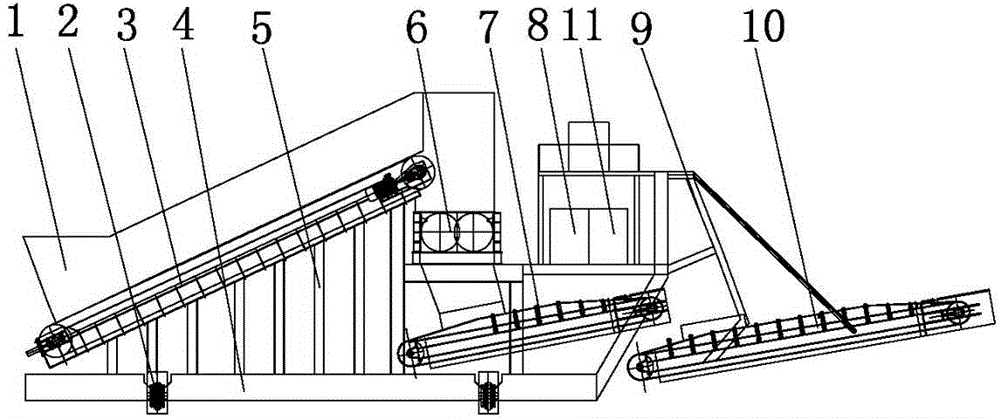

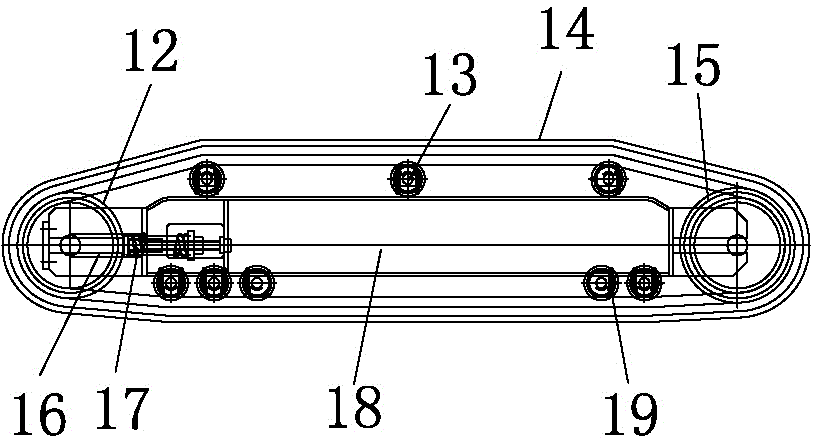

[0009] Depend on Figure 1-2 Given, the present invention comprises hydraulic station 11, electrical control box 8, crawler-type traveling device 2, base 4, belt conveyor one 10, hydraulic cylinder 9, belt conveyor two 7, crusher 6, heavy apron feeder 3 and material The warehouse 1 and the base 4 are fixed with a hydraulic station 11, an electrical control box 8, a crusher, a heavy apron feeder 3 and a belt conveyor 2 7, the base is fixed on the crawler-type walking device 2, and the heavy apron feeder 3 has material Warehouse 1, there is a crusher under the head of the heavy-duty apron feeder 3, there is a belt conveyor 2 7 at the lower part of the discharge port of the crusher 6, there is a belt conveyor 1 10 at the lower part of the discharge end of the belt conveyor 2 7, and the hydraulic station 11 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com