Gas-butting-type automatic-opening double-layer baking oven

An automatic opening and oven technology, applied in coating, device for coating liquid on surface, surface pretreatment, etc., can solve the problems of small operating space, high plant height requirements, inconvenient film penetration, etc., to prevent personal injury. Safety accident, large operation space, high automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

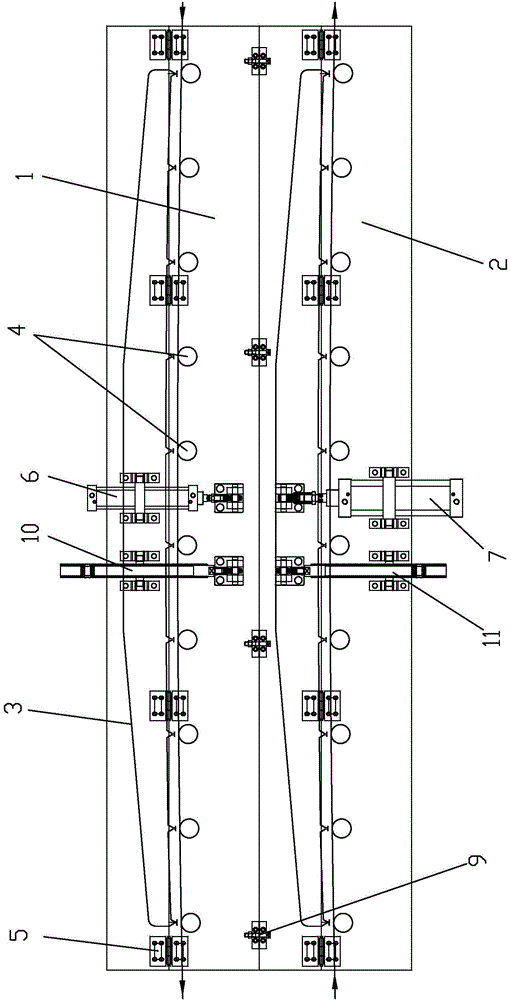

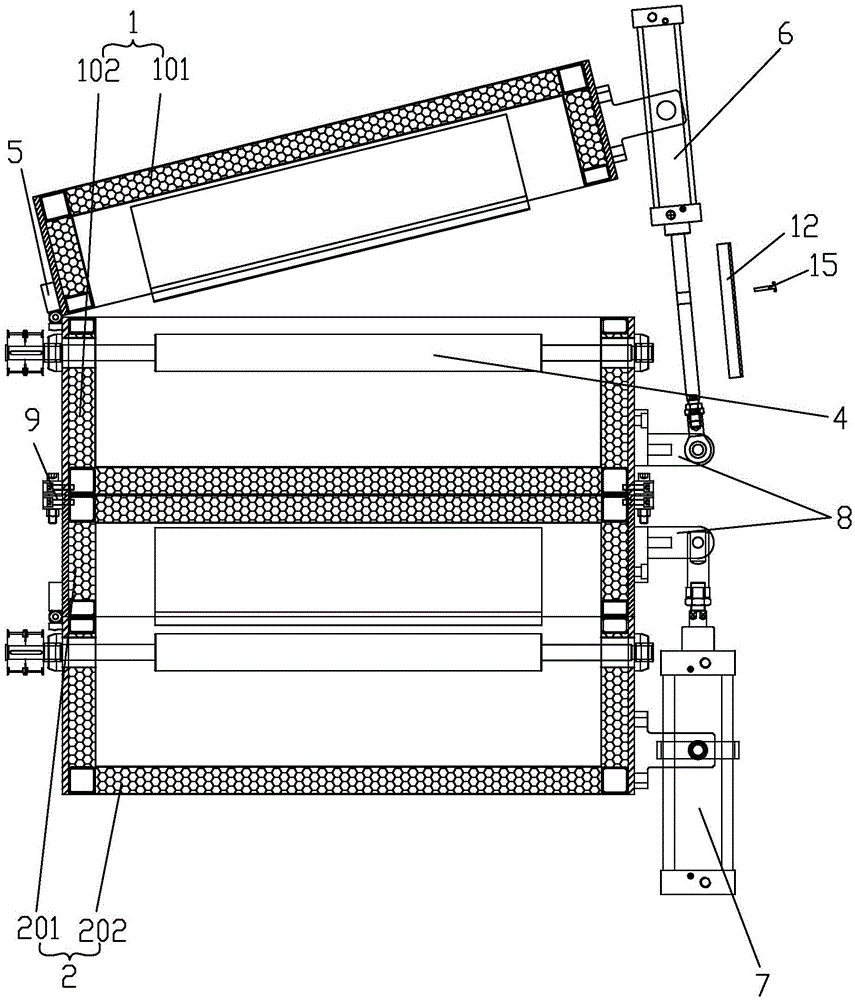

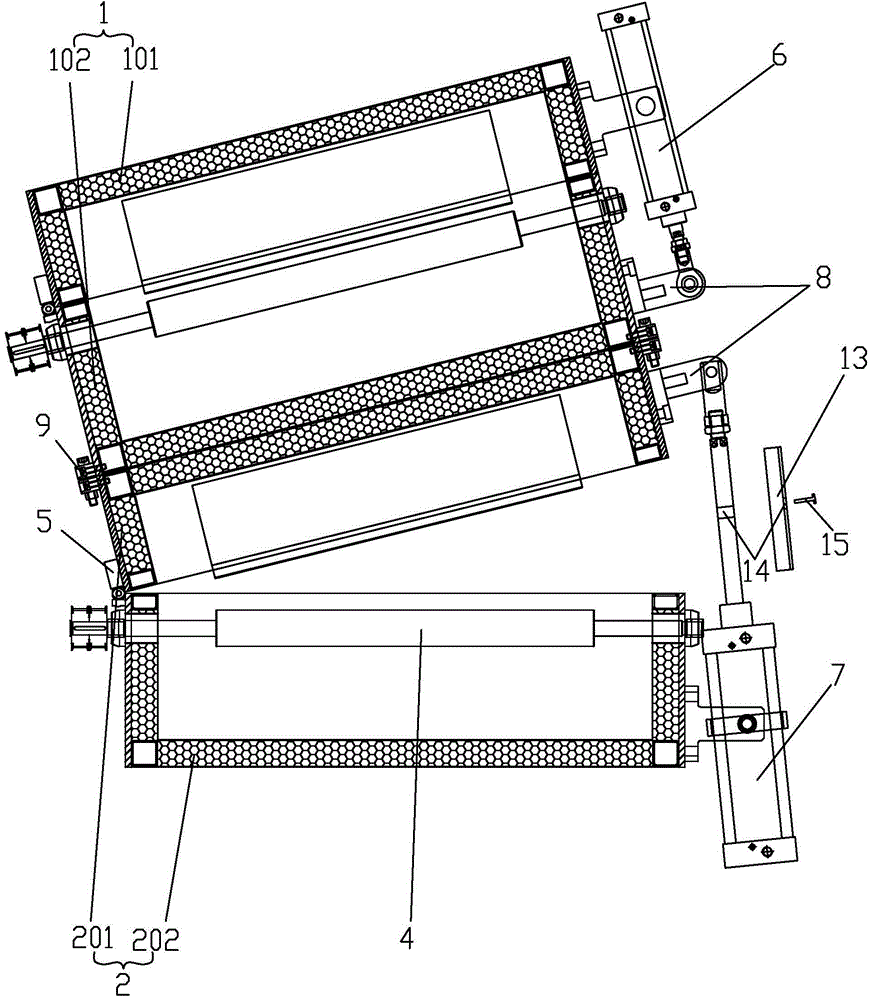

[0027] A gas-top type double-layer oven that is automatically opened, including an upper oven 1 for drying a substrate 3 and a lower oven 2 located below the upper oven 1, the upper oven 1 and the lower oven 2 are provided with a traction unit The transition roller 4 for the substrate 3 to move the film, the upper oven 1 includes an upper oven cover 101 and an upper oven box 102 that are hinged on one side through a hinge 5 and can be interlocked with each other, and the other side of the upper oven 1 There is an upper cylinder 6 that opens the upper oven 1 through the extension of the piston rod, and the lower oven 2 includes a lower oven cover 201 and a lower oven body 202 that are hinged on one side through a hinge 5 and can be interlocked. The other side of the lower oven 2 is provided with the lower cylinder 7 that opens the lower oven 2 by extending the piston rod, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com