Light Electric Slewing Hook Set

A hook group, electric technology, applied in the direction of load hanging components, load blocks, transportation and packaging, etc., can solve the problems of difficult parts processing, large volume and weight, complex structure, etc., to achieve stable combination, safe and reliable work , the effect of simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with drawings and embodiments.

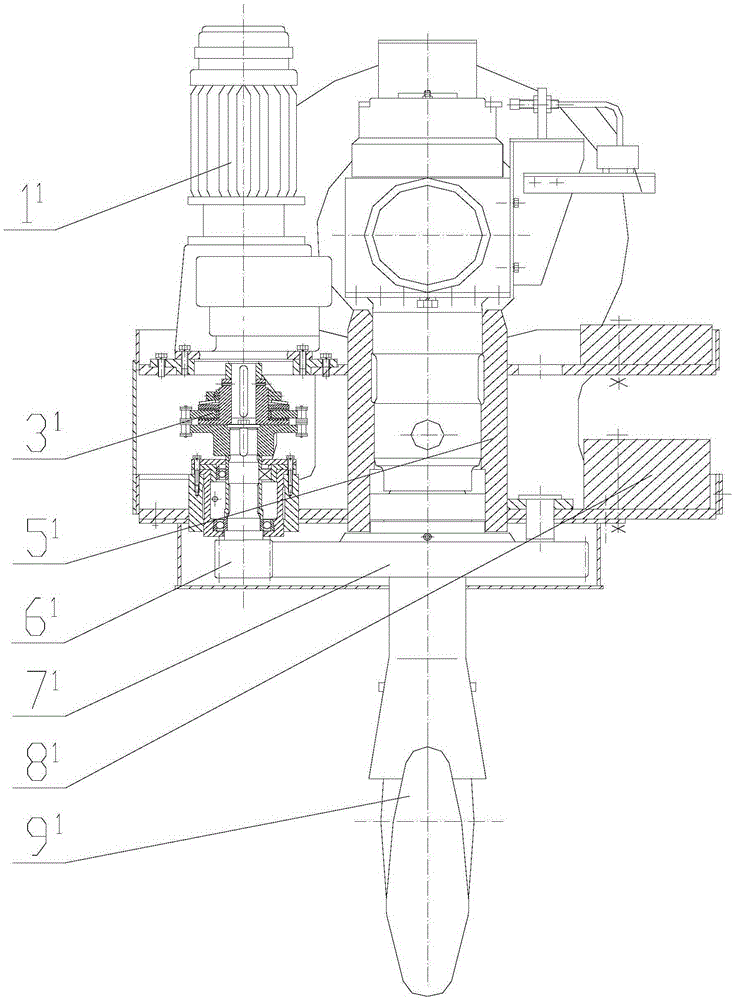

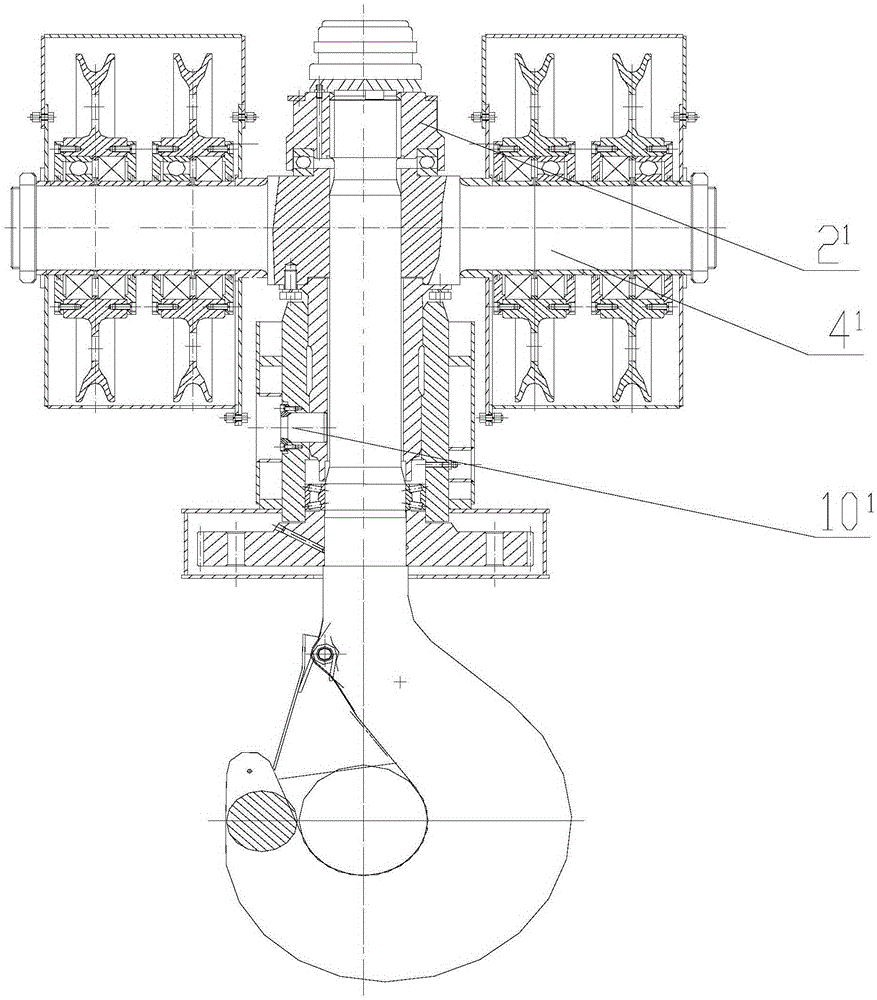

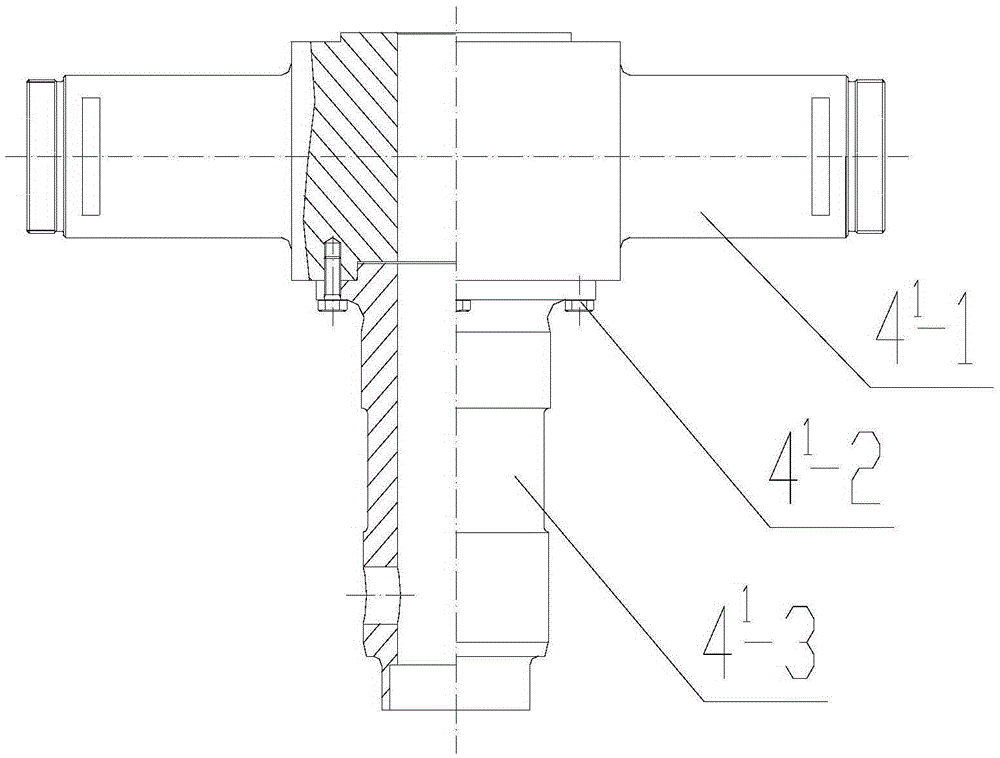

[0053] The light-duty electric slewing hook set includes a deceleration motor, a pulley mechanism, a gear mechanism and a hook mechanism. The deceleration motor 1 has a side flange and an end flange; the pulley mechanism includes a pulley shaft 2 and a pulley, and the two sets of pulleys are installed on the The two ends of the pulley shaft 2; the gear mechanism includes a pinion 13, a support 12 and a gear assembly 9, and the pinion 13 is fixed on the output shaft of the reduction motor 1 by a key 15; the support 12 is a conical frame, and the top surface of the support 12 is a large Ring, the small ring on the bottom surface is the bearing seat, the top surface of the support 12 is bolted to the flange of the reduction motor 1 end, the bearing 16 is installed in the bearing seat on the bottom surface of the support 12, the pinion 13 is supported on the bearing 16, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com