Flexible connecting pipeline and construction method for using flexible connecting pipeline in base isolated buildings

A flexible connection and construction method technology, which is applied in the direction of adjustable connection, pipeline laying and maintenance, pipe/pipe joint/pipe fitting, etc., can solve the problem of small displacement and deformation of metal bellows, common metal bellows are easy to have, and are not suitable for seismic isolation buildings and other issues, to achieve the effect of shortening the construction period, improving overall safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

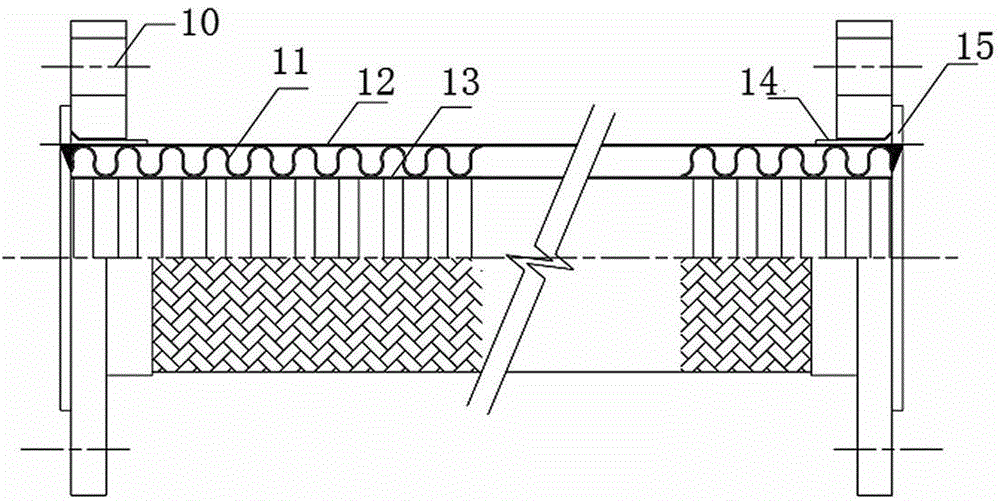

[0039] like figure 1 As shown, a flexible connection pipe 4 for earthquake-isolated buildings includes a corrugated pipe 11 and a joint 15 arranged at the end of the corrugated pipe 11, and a mesh sleeve 12 is sleeved on the outside of the bellows 11, and the mesh sleeve 12 and the joint The junction of 15 is fixed with net cover pressing ring 14, so that net cover 12 is fixed on the outside of bellows 11. In particular, a circular thermoplastic rubber liner 13 is provided inside the corrugated pipe 11 to improve the tensile strength and deformability of the flexible connecting pipe 4 and facilitate the removal of residues accumulated in the corrugated pipe 11 .

[0040] In order to prevent the rubber gasket 13 from collapsing under the pressure-free state, the rubber gasket 13 and the bellows 11 are bonded with Chemlock.

[0041] As a preference of this embodiment, the thickness of the rubber gasket 13 is 3 mm, the thickness of the single ring corrugation of the bellows 11 i...

Embodiment 2

[0052] Using the flexible connecting pipe 4 described in Embodiment 1, the thickness of the rubber gasket 13 is 3 mm, the thickness of the single ring corrugation of the bellows 11 is 1.8 mm, and the pitch between the corrugations is 3.5 mm.

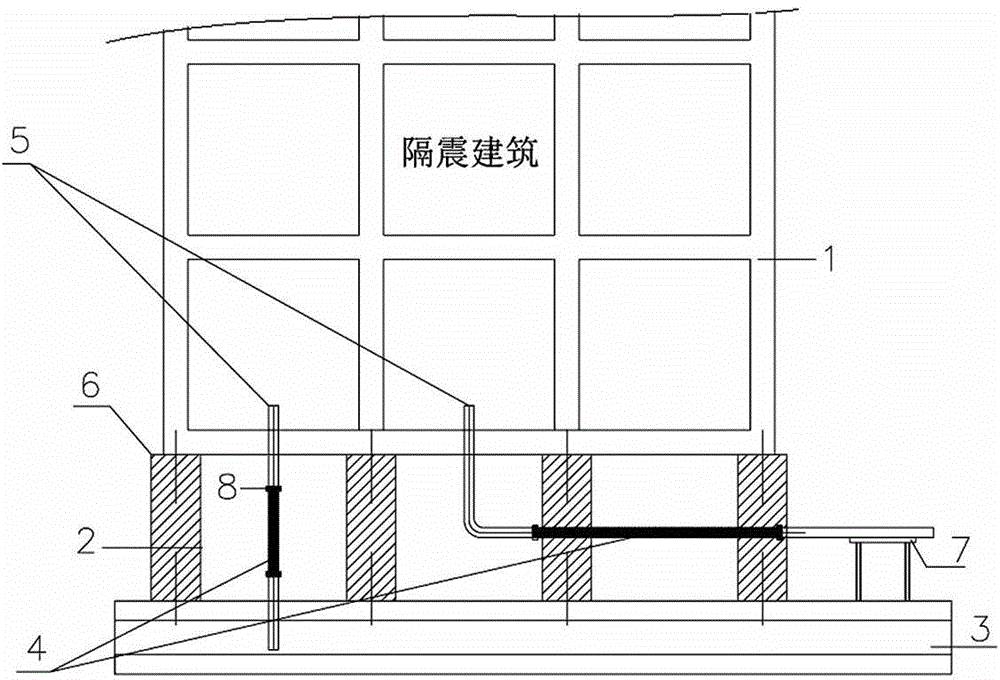

[0053] When the flexible connecting pipe 4 needs to be installed vertically, such as image 3 As shown, this embodiment provides the specific technological process for the installation of flexible connection pipes for earthquake-isolated buildings as follows:

[0054] Step 1: Determine the net height of the isolation layer 2, determine the net height of the isolation layer 2 according to the use of the isolation layer 2 (underground garage, basement, etc.), and further determine the installation position and length of the flexible connecting pipe 4, flexible The length of the connecting pipe 4 should meet the displacement requirement of not less than the displacement of the isolation support under rare earthquakes;

[0055] Step 2: Duri...

Embodiment 3

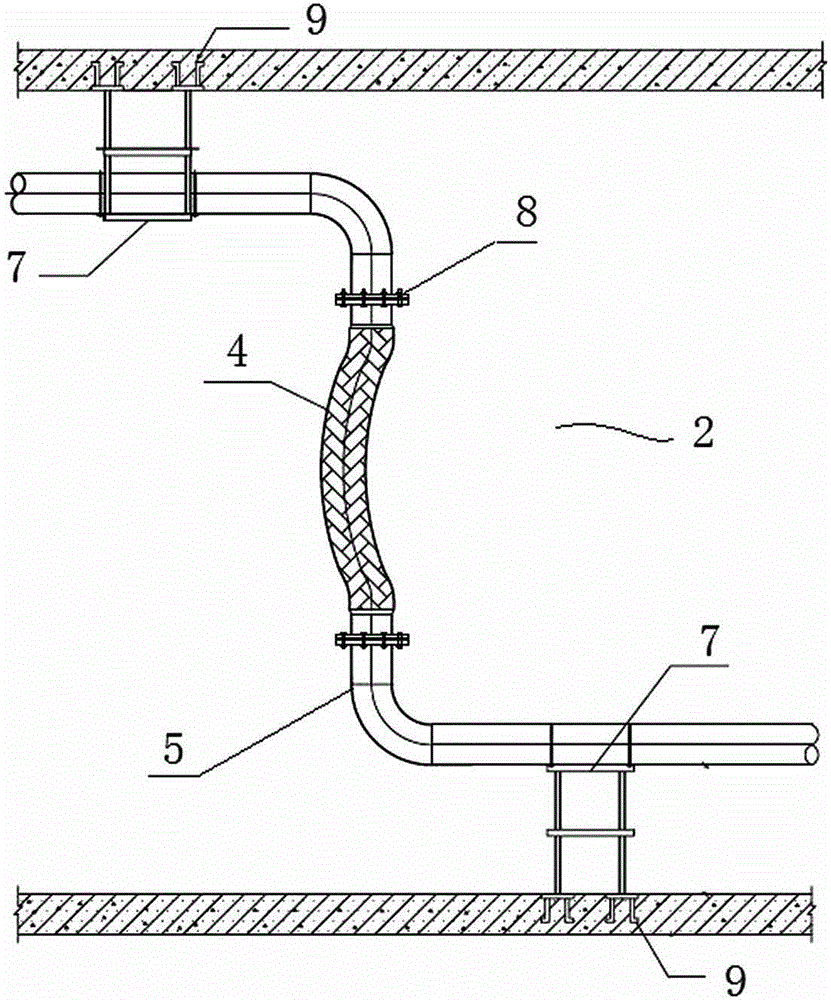

[0061] When the flexible connecting pipe 4 described in Embodiment 1 is installed in the shock-isolation layer 2 in a horizontal direction, as Figure 4 , Figure 5 and Figure 6 As shown, this embodiment provides the specific technological process for the installation of flexible connection pipes for earthquake-isolated buildings as follows:

[0062] Step 1: Determine the net height of the isolation layer 2, determine the net height of the isolation layer 2 according to the use of the isolation layer 2 (underground garage, basement, etc.), and further determine the installation position and length of the flexible connecting pipe 4, flexible The length of the connecting pipe 4 should meet the displacement requirement of not less than the displacement of the isolation support under rare earthquakes;

[0063] Step 2: Pre-embed the fixed platform embedded parts 9 at appropriate positions on the top and bottom plates of the seismic isolation layer 2, and lay a ground-type mobile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com