Acceleration sensor base with checking and calibration mechanism

An acceleration sensor and calibration technology, applied in the direction of measurement of acceleration, speed/acceleration/shock measurement, speed/acceleration/shock measurement equipment testing/calibration, etc., can solve the problems that the inspection work cannot be implemented, and the on-site calibration of the sensor can be achieved. Improve work efficiency and test accuracy, and reduce work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] like figure 1 As shown, an acceleration sensor base with an inspection and calibration mechanism includes a main drive system 1, a base box assembly 2, a support spring 3, a fixing bolt 4, a vibrating rod 5, a vibrating plate 6, and a roller 7.

[0030] 1. Main drive system ( figure 2 ): The main transmission system is mainly composed of a speed regulating motor 16, a coupling 17, a main transmission shaft 15, a rolling bearing assembly 13, a return spring 14, a position adjustment bolt 11, and a plane bearing 10. in:

[0031] 1) Speed-regulating motor 16: It generates the working speed during inspection and calibration, and its speed is adjustable.

[0032] 2) Coupling 17: Connect the speed regulating motor 16 and the main transmission shaft 15.

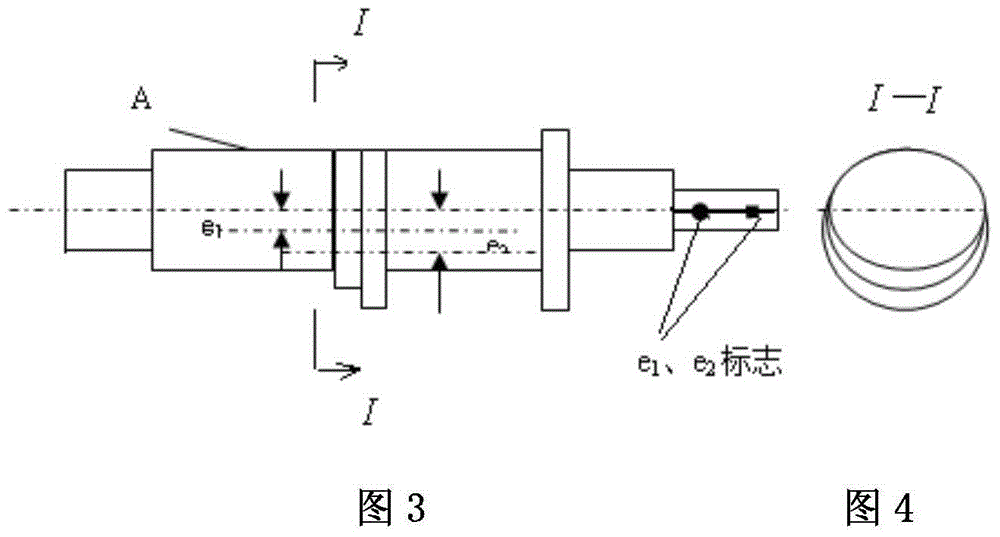

[0033] 3) Main drive shaft 15 ( image 3 , 4 ): Rotational movement is formed under the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com