Receiver part complex surface numerical control machining method

A technology for complex shapes and box-like parts, applied in the direction of digital control, electrical program control, etc., can solve problems such as different tangent points, low production efficiency, and lack of CNC machining technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

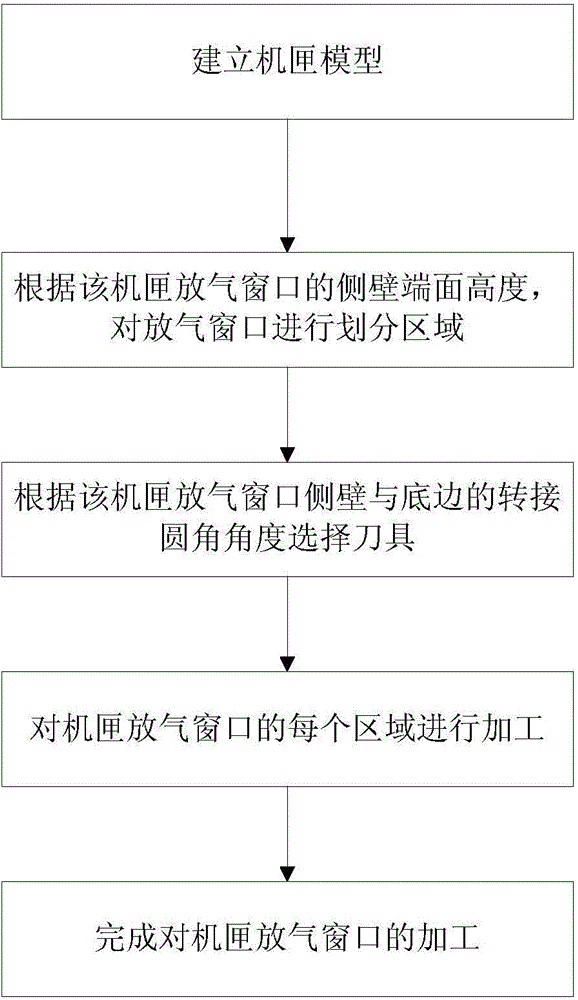

[0022] A numerical control machining method for the vent window of casing parts, the flow chart of the method is as follows figure 1 shown, including the following steps:

[0023] Step 1, establish the casing model;

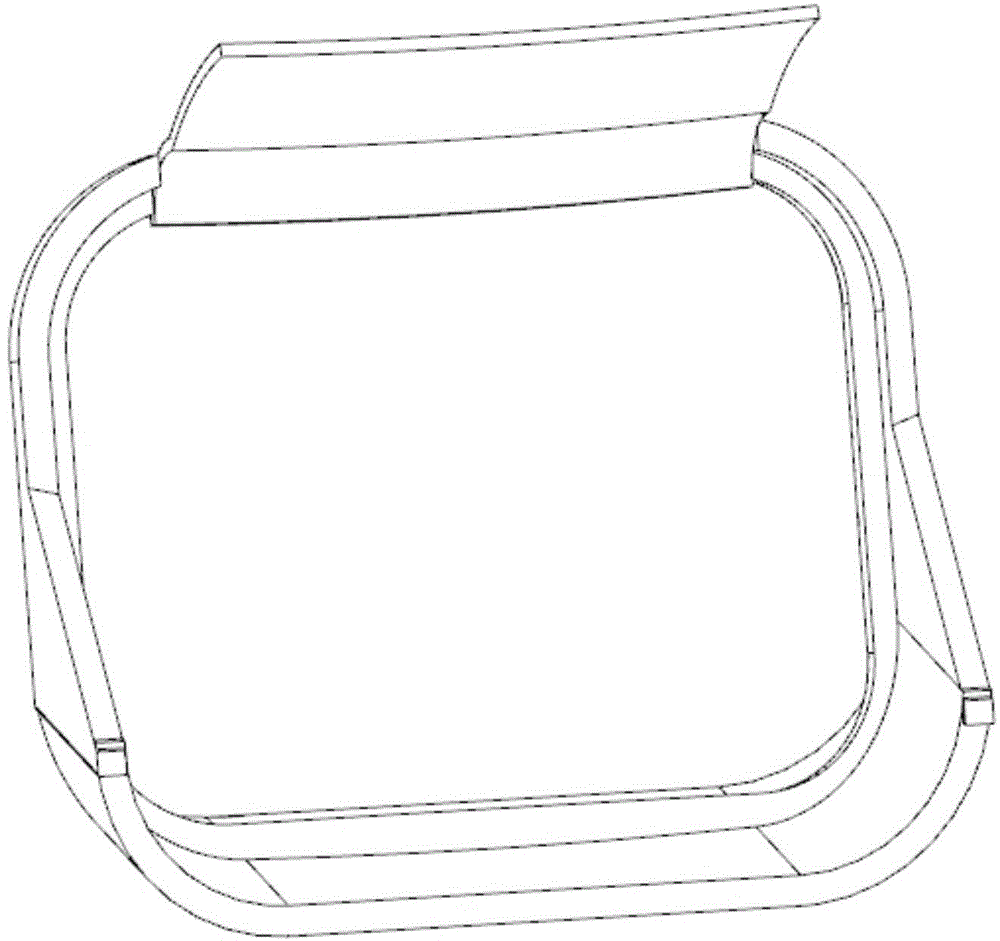

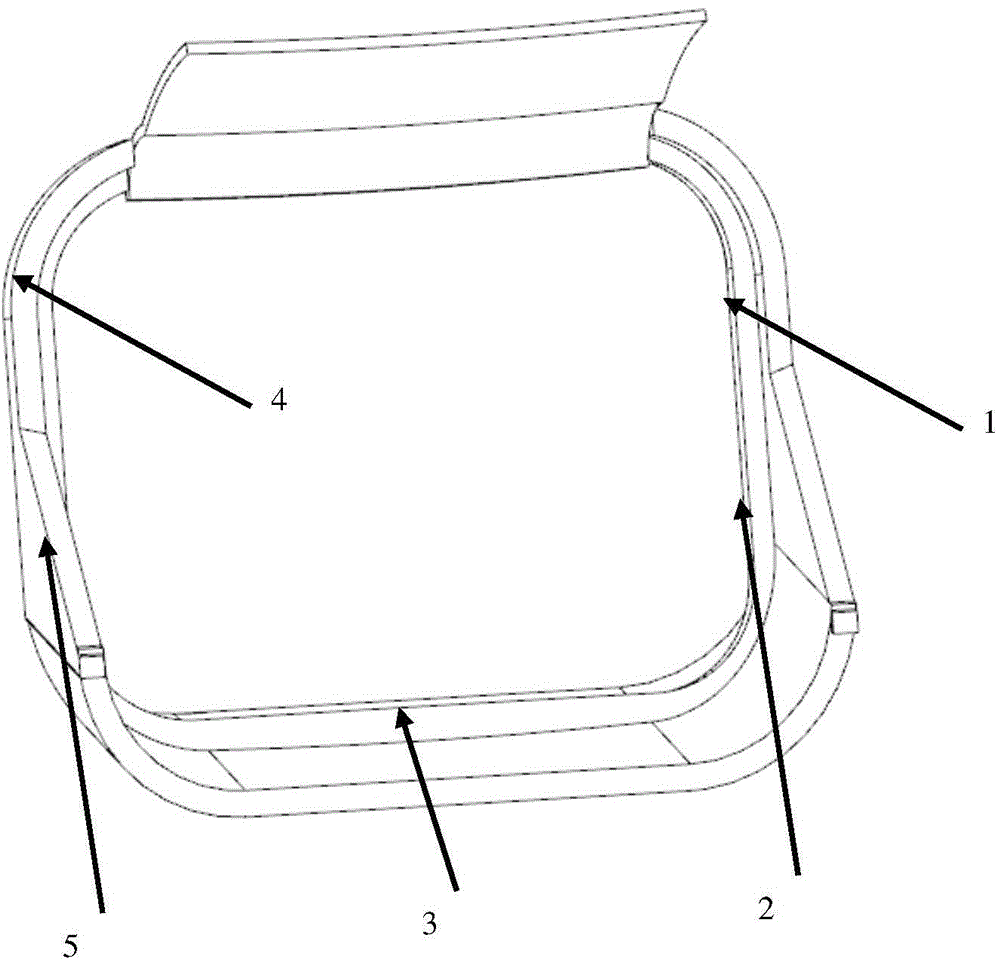

[0024] In the embodiment of the present invention, the basis for processing the deflation window is to create an accurate processing model, and only by relying on an accurate part model can a correct and reasonable tool path be created; therefore, in the embodiment of the present invention, UG is used to build Modeling and programming software creates a set of part models, such as figure 2 As shown, it laid the foundation for the subsequent programming work;

[0025] Step 2, according to the height of the side wall end surface of the air release window of the casing, the air release window is divided into regions;

[0026] When milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com