Motor stator punching plate

A stator punching and motor technology, which is applied to asynchronous induction motors, electric components, electrical components, etc., can solve the problems of large consumption of copper wires in windings, can not meet the requirements of saving and reduction, and low utilization rate of silicon steel sheets, and achieves reduction of copper wires. The effect of reducing dosage, production cost, and effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

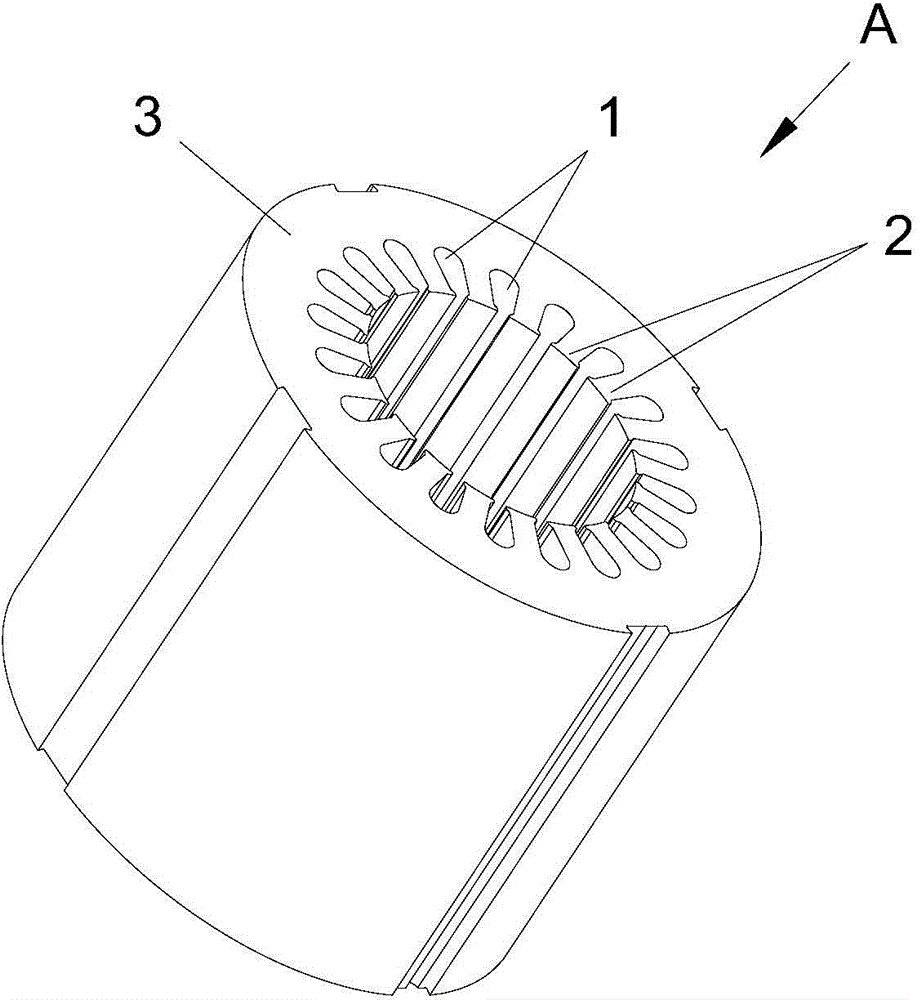

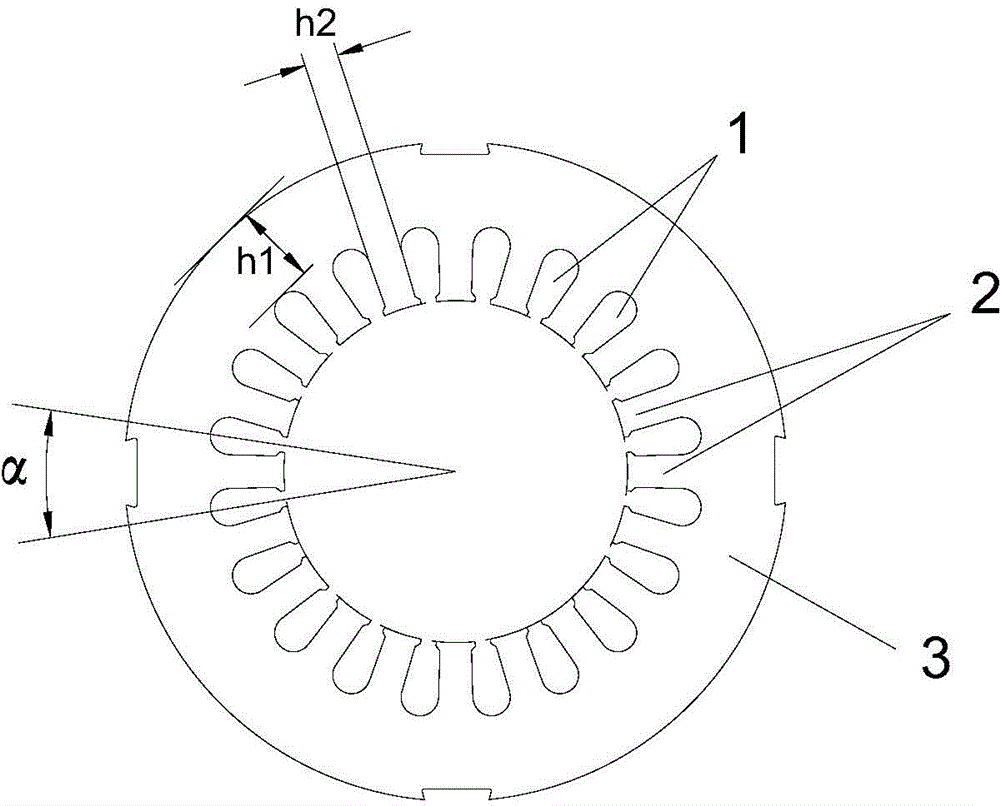

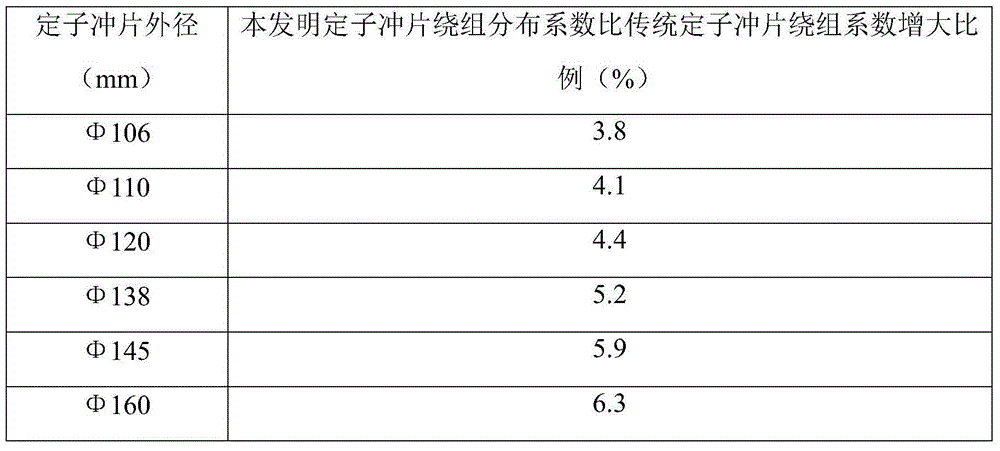

[0024] Such as figure 1 and figure 2 The structure of the motor stator punching sheet of the present invention shown in the figure is that the stator punching sheet is provided with winding slots 1 evenly arranged in phases with spaced teeth 2 along the circumference, and the area between the winding slot 1 and the outer periphery of the stator punching sheet is the stator punching sheet. The yoke of the sheet 3. The number of winding slots 1 is at least an odd multiple starting from 5 times of 4, but excluding common multiples of 4 and 6. Taking the number of winding slots 1 as a multiple of 5 of 20, and the outer diameter of the stator punching sheet as φ138mm as an example, the axis of the adjacent winding slot 1 and the angle α between the center point of the stator punching sheet is 18°, and the yoke 3 The length h1 is about 17mm, and the tooth width h2 is about 3.7mm, both of which are larger than the parameters of the traditional stator punch. Taking the YL series t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com