Serially connected electricity supply power supply for multi-stage depressed collector traveling wave tube

A series power supply, traveling wave tube technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of large volume and weight, complex implementation, large volume, etc., to meet system requirements, convenient circuit implementation, high power density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

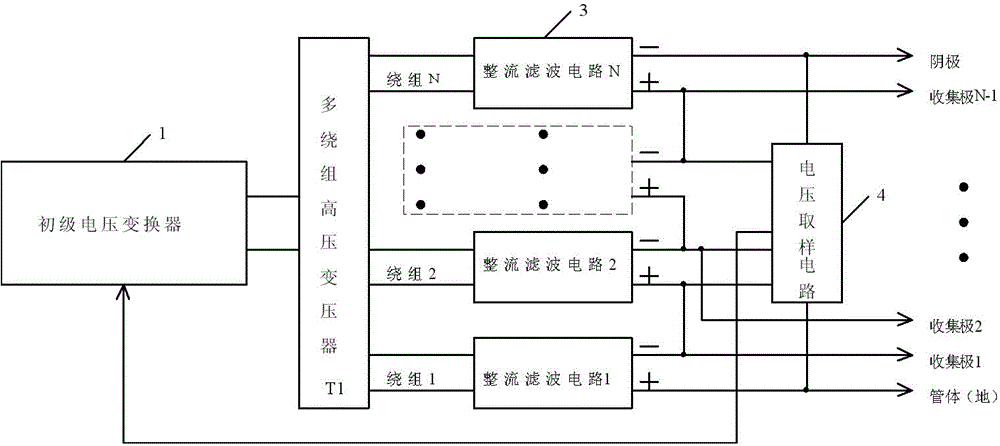

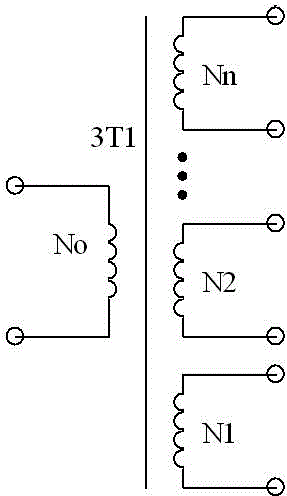

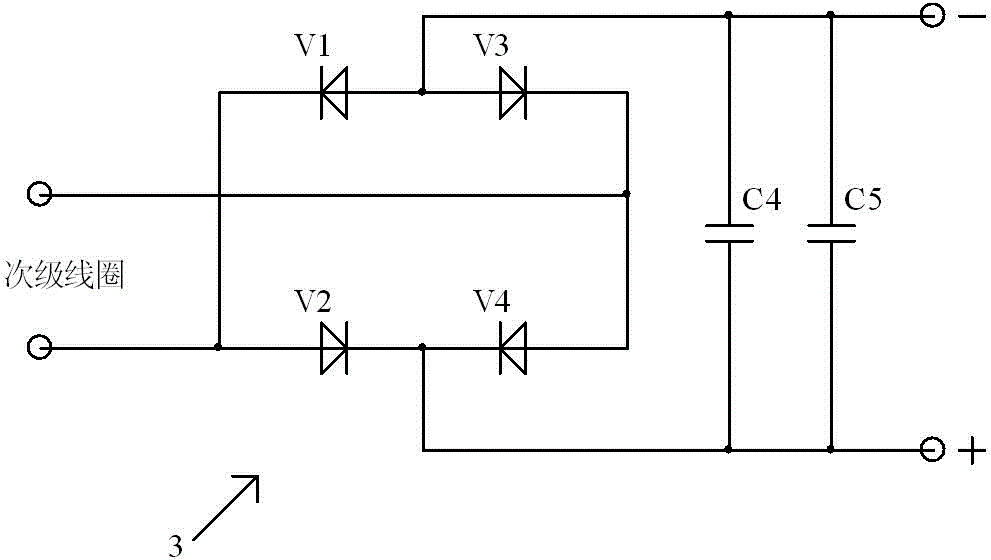

[0020] A series power supply for a multi-stage step-down collector traveling wave tube, including a primary voltage converter 1, the output terminal of which is connected to the primary coil N of a multi-winding high-voltage transformer T1 0 The N secondary coils of the multi-winding high-voltage transformer are respectively connected to the input terminals of N rectifier filter circuits 3, N≥2, the output positive terminals of two adjacent rectifier filter circuits 3 are connected to the output negative terminals, the first The output positive terminals of the rectifying and filtering circuits 3 are connected to the tube body of the traveling wave tube, the output negative terminals of the first to N-1 rectifying and filtering circuits 3 are respectively connected to the N-1 collecting poles of the traveling wave tubes, and the Nth rectifying The negative output terminal of the filter circuit 3 is connected to the cathode of the traveling wave tube, and the output terminal of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com