A stage curtain opening and closing device

A technology for opening and closing devices and stage curtains, which is applied to stage devices, devices used in theaters, circuses, etc., entertainment, etc. It can solve the problems of easy breakage of steel wires and inability to bend and move steel wires, and achieve load reduction and small tightening force , to ensure the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

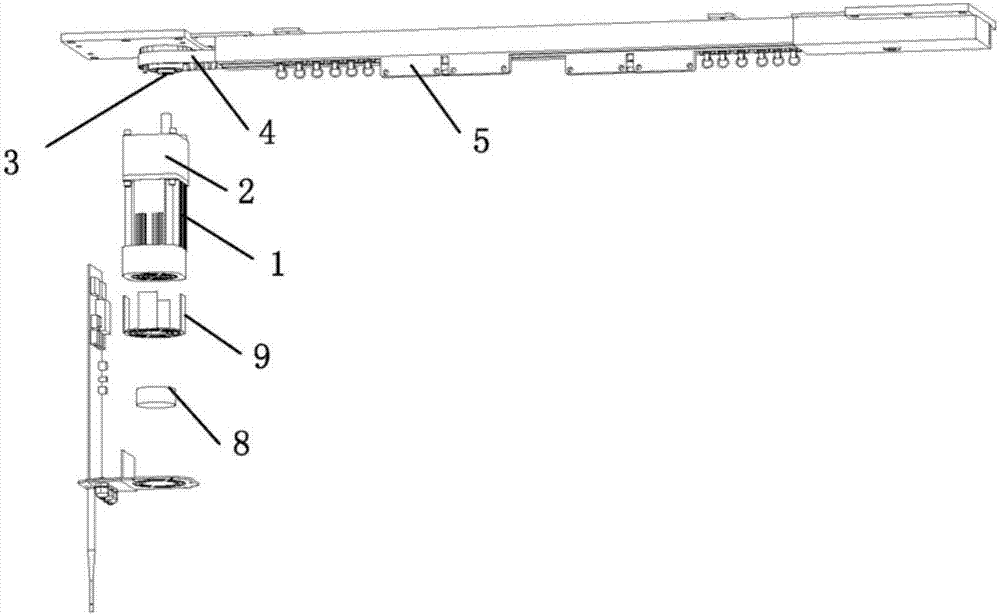

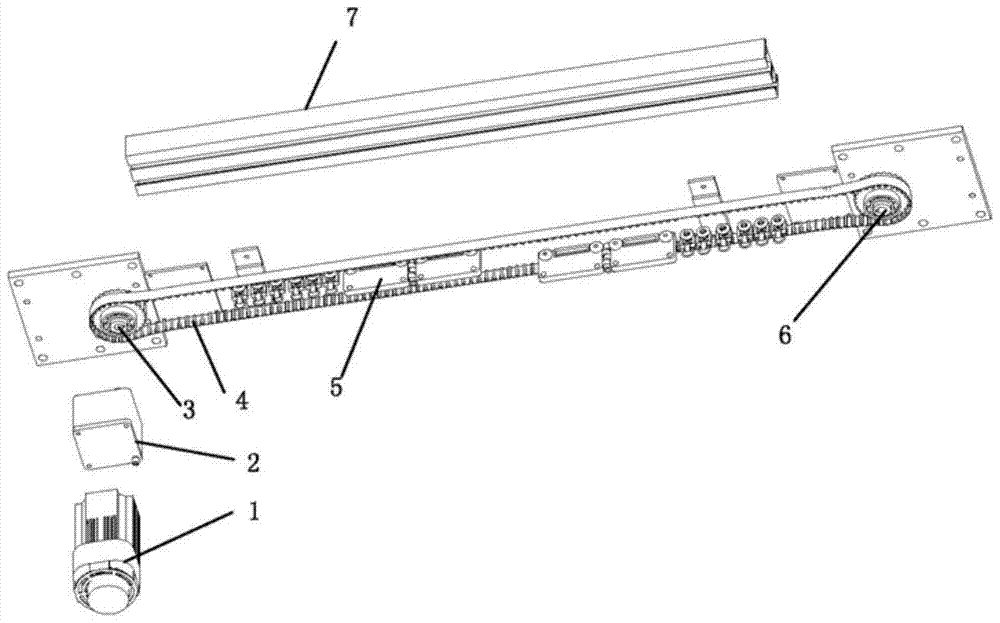

[0027] A stage curtain opening and closing device, such as figure 1 As shown, a track 7, a motor, a transmission mechanism and a pulley 5 are provided, and the motor drives the pulley 5 to move through the transmission mechanism. The transmission mechanism includes a main gear 3, a driven gear 6 and a synchronous belt 4, and the synchronous belt 4 is wound around The motor is drivingly connected to the main gear 3 and the driven wheel, and the synchronous belt 4 moves along the track 7 .

[0028] The transmission mechanism of the present invention transmits power movement through the meshing of the toothed belt and the gear, and the toothed belt and the gear are closely connected, so there is no relative sliding between the toothed belt and the gear, which can ensure an accurate transmission ratio, ensure stable transmission, and increase transmission efficiency. The load capacity of the mechanism is that the longest track 7 is 30 meters long;

[0029] The synchronous belt 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com