Automatic loading and unloading device for punching machine

A technology of automatic loading and unloading, automatic feeding, applied in the direction of feeding device, peeling device, positioning device, etc., can solve the problems of high labor intensity, poor safety, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

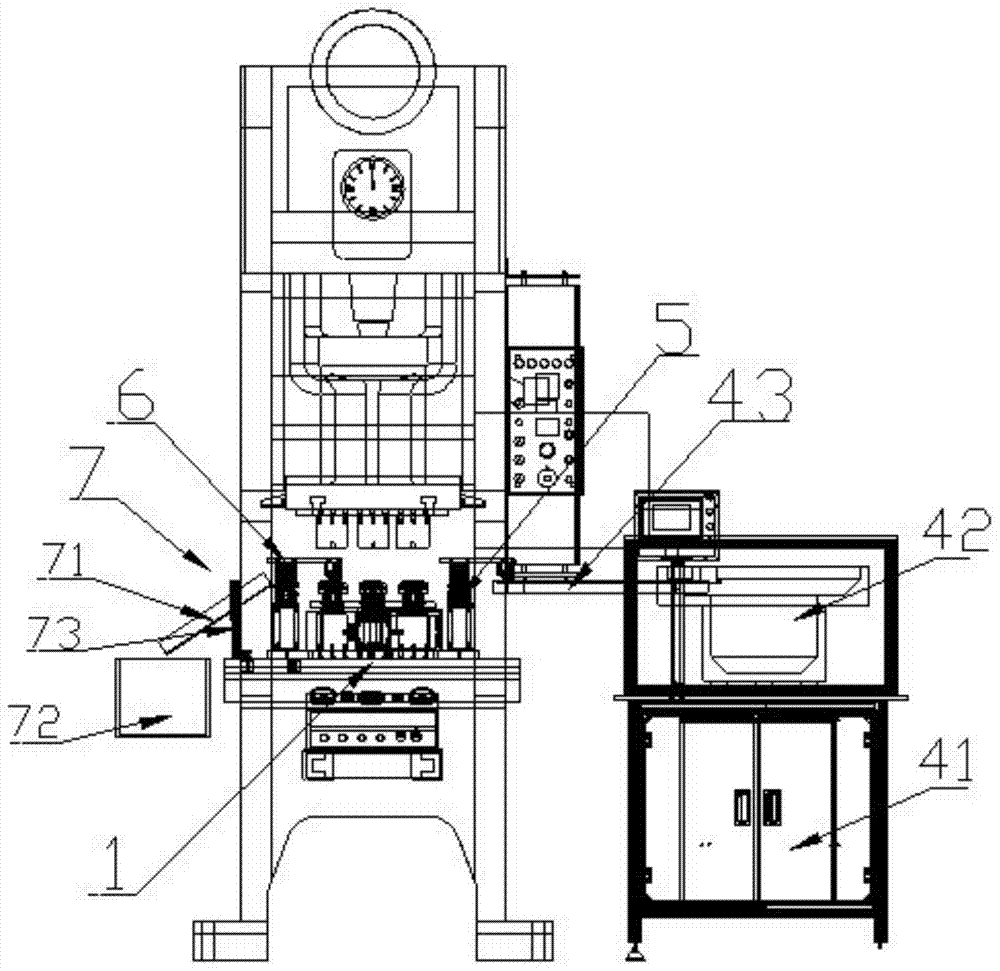

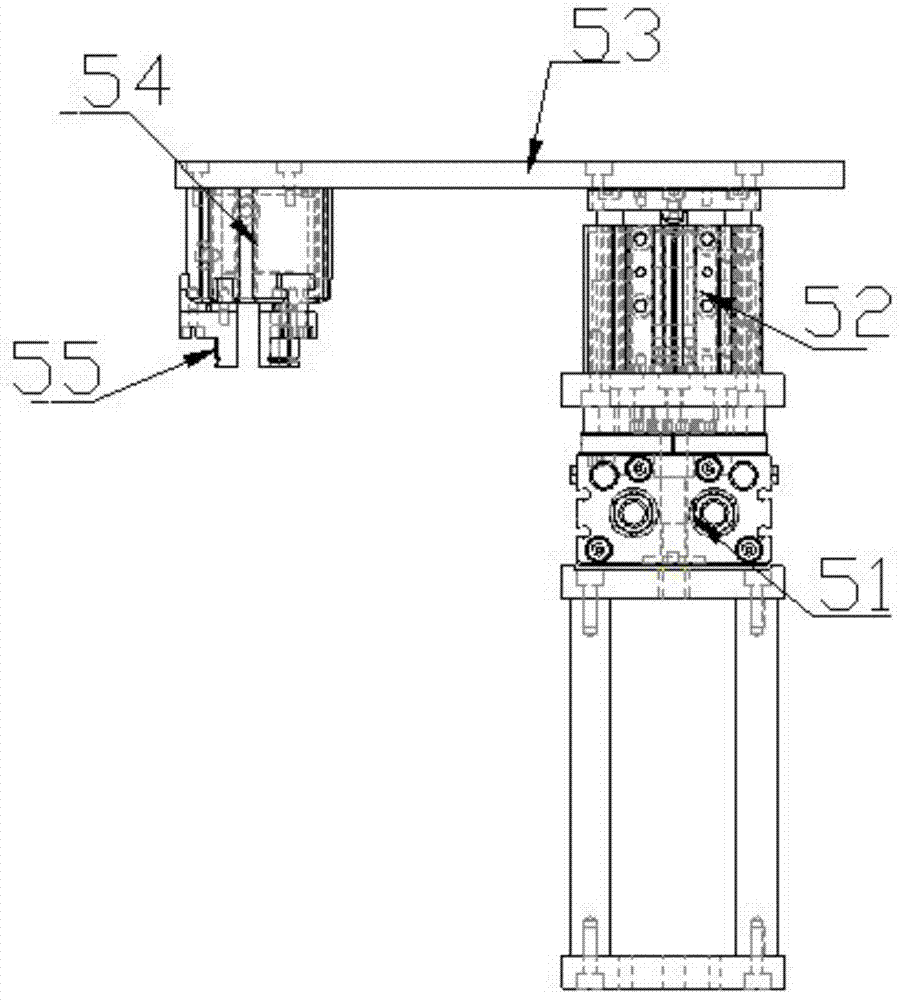

[0013] as attached figure 1 , 2 Shown is a kind of automatic loading and unloading device used in punching press according to the present invention, automatic feeding mechanism and automatic blanking mechanism; The automatic feeding mechanism includes a frame 41 arranged on one side of the punching machine platform 1, The vibrating plate 42, the automatic reclaiming manipulator 5 and the linear guide rail 43 extending from the vibrating plate 42 to the automatic reclaiming manipulator 5 arranged above the frame 41; the automatic feeding manipulator 5 includes a rotary cylinder 51 and a three-axis cylinder 52 , connecting plate 53, three-claw cylinder 54 and jig 55; the three-claw cylinder 52 is arranged above the rotary cylinder 51; one end of the connecting plate 53 is connected to the piston end of the three-claw cylinder 52, and the three-claw cylinder 54 is set At the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com