Wire-free guide wire

A wire guide nozzle and wire threading technology, which is applied to the field of online cutting equipment, can solve the problems of high difficulty in threading, damage to the wire guide structure and workpiece, and low replacement frequency, so as to reduce the time for threading and use and reduce the investment in use. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

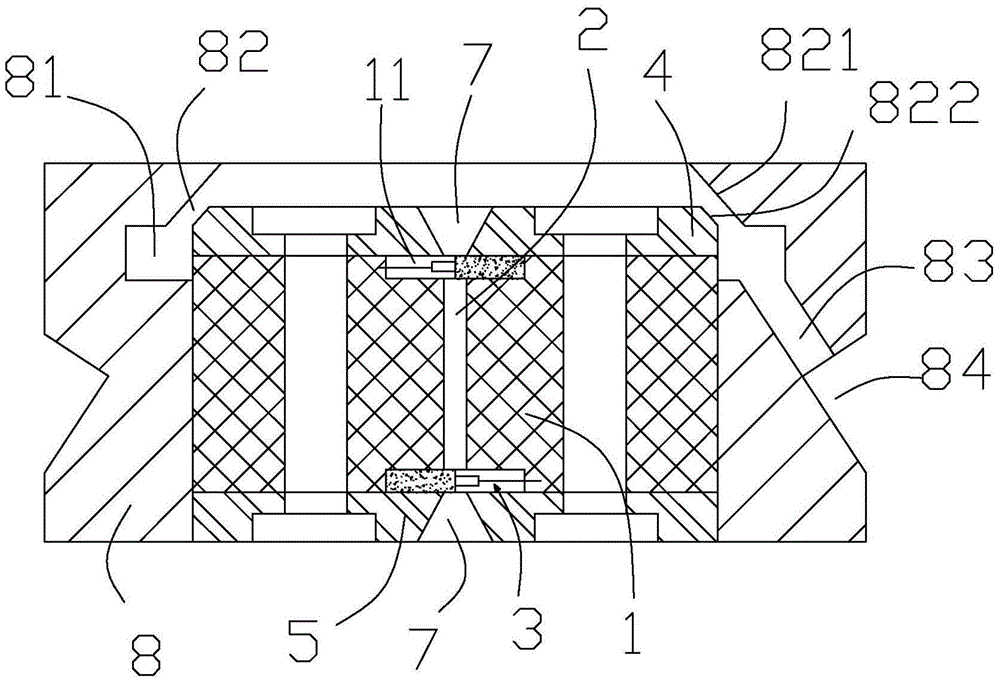

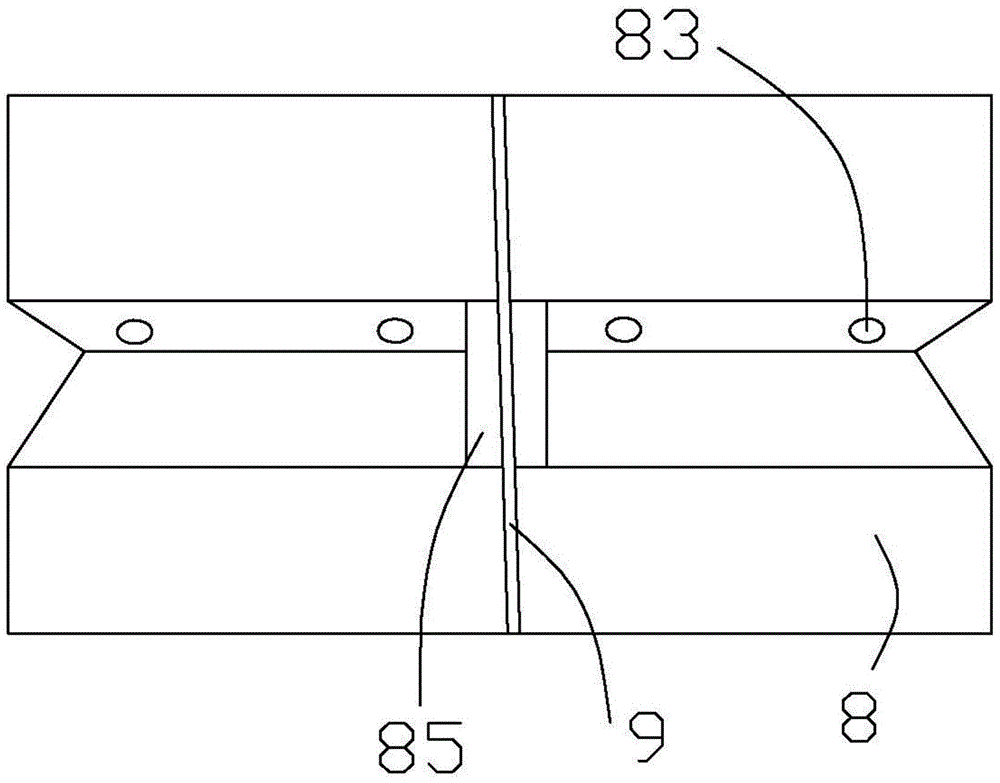

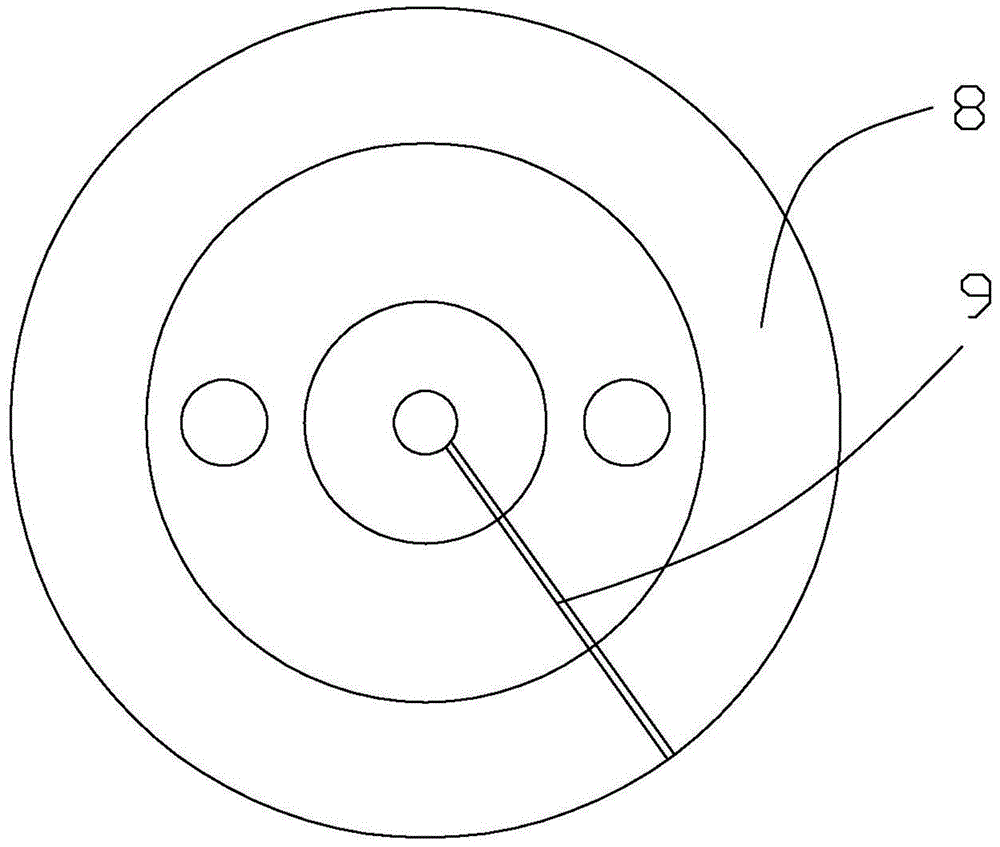

[0029] refer to Figure 1 to Figure 4 As shown, the wire-free guide nozzle includes a cylinder 1, a central hole 2 passing through the top and bottom of the cylinder is arranged in the middle of the cylinder, and a wire positioning device 3 is arranged on the cylinders at both ends of the central hole, and two wire positioning devices On the contrary, it is arranged and fixed on the cylinder by the upper guard plate 4 and the lower guard plate 5 respectively. The silk thread positioning device is made up of a positioning block 31 and a one-way passage device 32. A semicircle positioning hole 6 is arranged on one side of the positioning block. The semicircle positioning hole Located above the central circular hole, the upper guard plate and the lower guard plate at both ends of the central circular hole are also provided with a round table structure avoidance hole 7, and the outer sheath 8 is fixed on the cylinder, and the outer sheath is located on the side of the upper guard p...

Embodiment 2

[0040]The difference between Embodiment 2 and Embodiment 1 is that the angle between the wire inlet and the bottom of the outer sheath is 85 degrees, and the wire inlet width is 0.5 mm. When molybdenum wire is set, the large angle and large width can ensure that the operator pushes it in. The smoothness, the setting is more convenient, and the precision requirement of processing is also reduced.

Embodiment 3

[0042] The difference between Embodiment 3 and Embodiment 1 is that the angle between the wire inlet and the bottom of the outer sheath is 88 degrees, the wire inlet width is 0.3 mm, and the angle is closer to the vertical angle, which reduces the pulling of the molybdenum wire and the molybdenum wire. damage. The smaller width can ensure that the molybdenum wire is pushed in close to the positioning block, so that the force is minimal and labor-saving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com